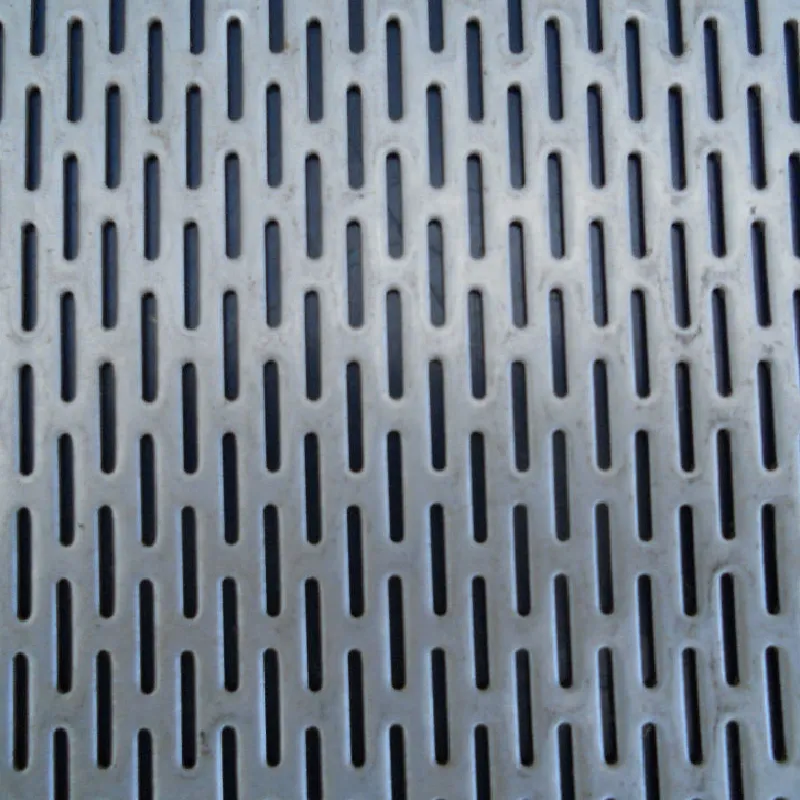

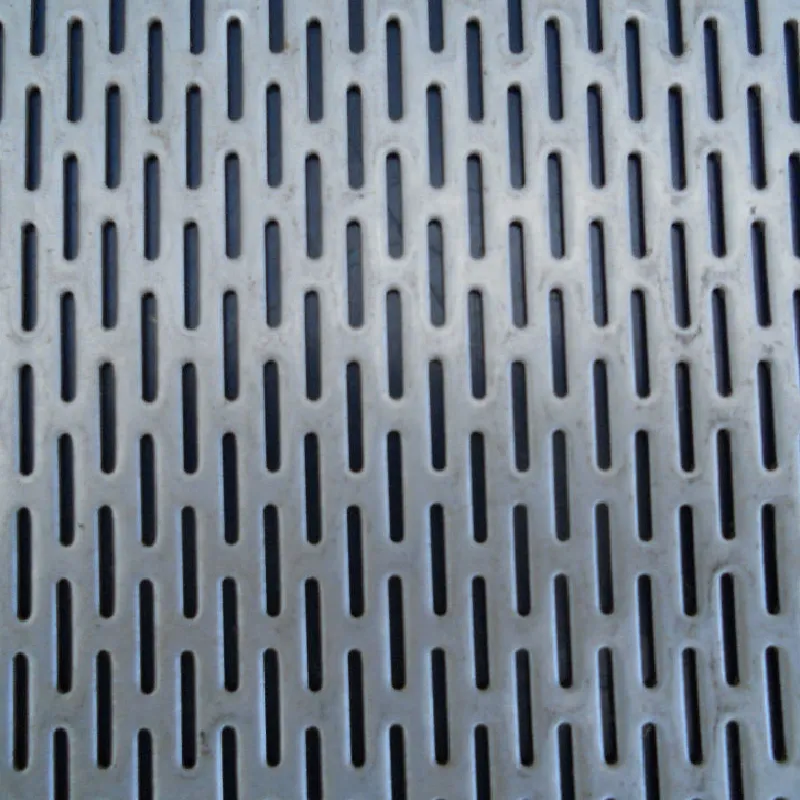

Steel bar grating represents an essential component in various architectural and industrial applications. Its versatility and robustness are evident in infrastructure developments worldwide, providing optimal solutions for structural support, safety, and aesthetic needs.

The use of steel bar grating stems from its high strength-to-weight ratio, corrosion resistance, and superior load-bearing properties. These characteristics make it the ideal choice for platforms, walkways, and stair treads in both commercial and industrial settings. The open-grid construction ensures maximum ventilation and drainage, critical for maintaining safety and longevity in environments prone to moisture and weather-related challenges.

A profound understanding of the manufacturing process further highlights the expertise ingrained in steel bar grating's development. The process involves joining steel bars at intersecting points with a welding process under immense heat and pressure, ensuring durability and longevity. This methodology provides unrivaled structural integrity, allowing the grating to withstand heavy loads and intense use over time.

The steel used in grating is typically of high quality, further asserting the product's authoritativeness in heavy-use applications. It is carefully selected to meet stringent international standards, assuring clients of its reliability. For instance, galvanized or stainless steel variants offer enhanced protection against rust, effectively reducing maintenance needs and increasing the lifespan of the installations.

Incorporating steel bar grating into a design requires a strategic approach. The open nature is not only functional but adds an industrial aesthetic appeal, increasingly popular in modern architecture. The design possibilities are extensive, with various bar sizes and spacing options available, enabling customization according to specific project requirements. This customization is fundamental to achieving desired safety, functionality, and aesthetic outcomes.

steel bar grating

Professionals across industries have consistently endorsed steel bar grating for its trustworthiness. Facility managers, architects, and engineers rely on its proven record to provide dependable service in demanding scenarios. The durability of steel grating ensures it performs remarkably under pressure, providing peace of mind in environments where safety is paramount.

Moreover, the expertise required to select the right type of steel bar grating cannot be overstated. Comprehensive knowledge of load requirements, environmental conditions, and regulatory standards is essential to making informed decisions. Furthermore, expertise in installation techniques ensures the grating performs optimally over its lifespan, mitigating risks associated with improper fitting and use.

Emerging trends in steel bar grating involve sustainable practices. As the world moves towards greener construction solutions, steel grating is increasingly being included in eco-friendly projects. Its recyclability and energy-efficient production processes position it as a conscientious choice for environmentally responsible construction efforts, thus enhancing its credibility further in the industry.

The evolution of steel bar grating has also embraced advanced technologies. Innovations in manufacturing and materials science have allowed for lighter, more robust structures. These advancements continue to shape the industry, driven by a commitment to improving safety and efficiency while maintaining economic viability for stakeholders.

In conclusion, steel bar grating stands as a paragon of structural and aesthetic utility. Its comprehensive benefits extend beyond mere functionality. This component embodies a fusion of experience, expertise, and reliability, continually proving itself indispensable across a spectrum of applications. For decision-makers in architecture and industrial design, steel bar grating offers a timeless solution, founded on resilience and informed by years of proven success.