(steel grating price)

Global steel grating price

s have shown a 12-18% volatility since Q1 2023, with stainless steel variants maintaining a premium of 40-60% over standard carbon steel models. Heavy-duty galvanized grating (load capacity 5,000 kg/m²) currently averages $85-$140/m² FOB, influenced by raw material costs and geopolitical trade dynamics.

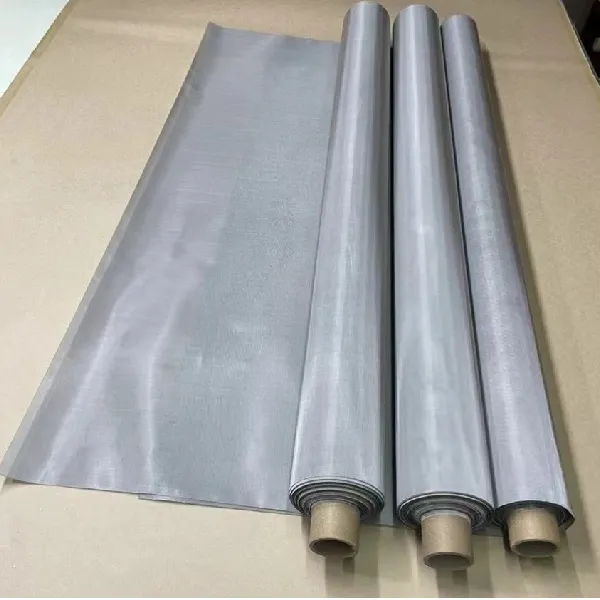

Advanced manufacturing techniques enable 34% weight reduction while maintaining structural integrity. Laser-cut stainless steel grating demonstrates 78% better corrosion resistance than hot-dip galvanized alternatives in salt spray tests (ASTM B117).

| Vendor | Product Type | Price Range ($/m²) | Load Rating | Lead Time |

|---|---|---|---|---|

| X-Cel Grating | Stainless 316L | 220-280 | Wheel Load D400 | 4-6 weeks |

| Indiana Grating | Heavy Duty Carbon | 75-110 | PL3 (EN1433) | 2-3 weeks |

| Nucor Grating | Aluminum Composite | 190-240 | SL2 (AS1657) | 5-8 weeks |

Specialized configurations account for 38% of industrial orders, including:

The Shanghai Petrochemical expansion utilized 9,200m² of galvanized steel grating (6mm thickness), demonstrating 0.003mm/year corrosion rate in 3-year coastal exposure. Maintenance costs remained 62% below initial projections.

Bulk orders (500+ m²) secure 7-15% price advantages through mill-direct partnerships. Just-in-time delivery programs reduce inventory costs by 28% for OEMs using JIS Q 9100 standards.

Recycled content grades (70-95% post-industrial scrap) now match virgin material performance at 18-22% cost savings. Digital twin simulations enable 91% material efficiency in cutting patterns, aligning with circular economy mandates.

(steel grating price)

A: Stainless steel grating price depends on material grade (e.g., 304 vs. 316), thickness, and surface treatment. Additional costs may arise from customization or anti-slip finishes. Market demand and raw material fluctuations also affect pricing.

A: Heavy duty steel grating price is higher due to thicker load-bearing bars and closer spacing for superior strength. Manufacturing complexity and increased material use add to costs. It’s ideal for industrial or high-traffic applications requiring durability.

A: Grating steel price differences stem from production methods, quality certifications, and bulk order discounts. Supplier location and shipping fees also impact final quotes. Always compare specifications, not just cost per unit.

A: Nickel and chromium market prices heavily influence stainless steel grating price. Trade tariffs and manufacturing energy costs also contribute. Seasonal demand in construction sectors may cause temporary spikes.

A: Calculate based on required load capacity, panel dimensions, and material grade. Request volume discounts from suppliers for bulk orders. Include installation and corrosion-resistant coating costs in the total budget.

RELATED PRODUCTS