When navigating the realm of construction and industrial applications, stainless steel welded mesh emerges as a robust and versatile solution. This exceptional product, renowned for its strength, durability, and resistance to corrosion, has garnered significant attention from engineers, construction professionals, and industrial experts globally.

Stainless steel welded mesh is manufactured by welding intersecting rows and columns of steel to create a grid-like pattern. This design not only ensures high tensile strength but also enhances its ability to withstand harsh environments. The material’s inherent resistance to rust and corrosion makes it an ideal choice for both outdoor and indoor use, outlasting many alternatives and thus providing long-term value and reliability.

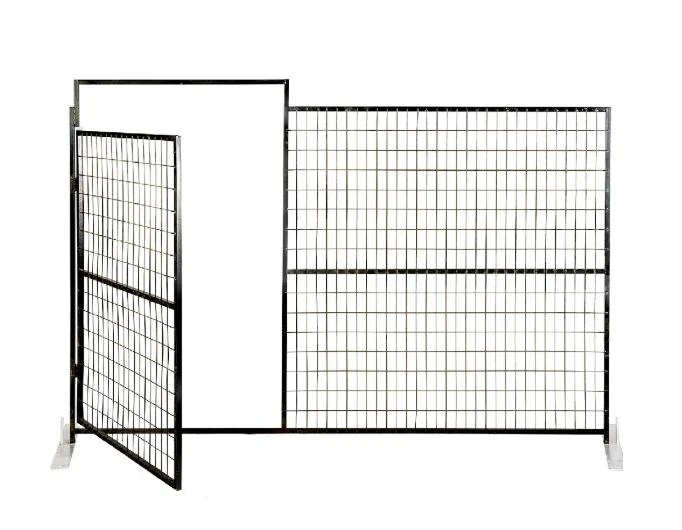

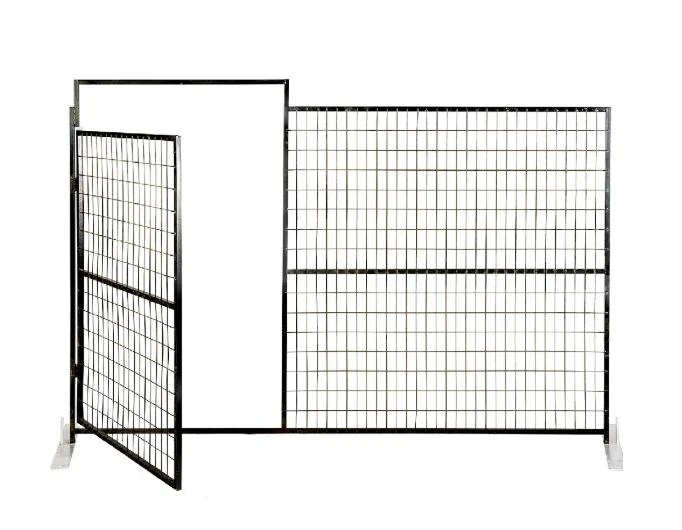

One of the principal benefits of stainless steel welded mesh is its adaptability. It is extensively used in a variety of applications ranging from fencing and security barriers to architectural cladding and agricultural enclosures. For example, in architectural projects, the mesh serves both aesthetic and functional purposes. Its modern and sleek appearance adds contemporary flair to facades and interior designs, while its structural integrity ensures safety and support.

In the realm of agriculture, stainless steel welded mesh acts as an outstanding solution for animal enclosures and plant support systems. Its resistance to weather and ability to withstand animal pressure without deformation make it a preferred choice among farmers and agricultural professionals. Conceivably, this material plays a vital role in protecting livestock and ensuring crop safety against pests and environmental factors.

Industry professionals appreciate stainless steel welded mesh for its role in security applications as well. With its unmatched toughness and resistance to tampering, it is a cornerstone of security fencing and barriers around sensitive areas such as power plants, airports, and military facilities. This mesh, in combination with additional security technologies, provides an almost impervious barrier to unauthorized entry, thus safeguarding vital infrastructure.

stainless steel welded mesh

From an expert perspective, the selection of stainless steel grade is crucial when considering welded mesh for a specific application. Grades such as 304 and 316 offer excellent corrosion resistance, but understanding the specific environmental conditions is critical for ensuring optimal performance. Grade 316, for instance, contains molybdenum, which augments its ability to withstand saline environments, making it a prime choice for coastal applications.

Trustworthiness in the choice of material manufacturer is paramount. When sourcing stainless steel welded mesh, it is essential to rely on manufacturers with a proven track record of producing high-quality, certified products. This confidence is often supported by adherence to international quality standards, which guarantees that the mesh can withstand the necessary pressures and environmental conditions it will face.

Moreover, the manufacturing process plays a significant role in determining the quality of the final product. Advanced welding techniques and precision engineering ensure that the mesh retains its properties and meets stringent industry standards. Professionals in the field consistently advocate for products that have undergone rigorous testing to validate their strength and durability.

In conclusion, stainless steel welded mesh serves as an indispensable asset across various sectors, offering unparalleled benefits in terms of durability, versatility, and performance. The material’s adaptability to diverse applications underscores its value and ensures its continual demand. Through careful selection of grade, credible sourcing, and adherence to best manufacturing practices, professionals can assure the effective implementation and long-lasting benefits of stainless steel welded mesh in their respective domains.