Stainless steel mesh sheets have become an integral component in numerous industries, playing a crucial role due to their exceptional durability, corrosion resistance, and versatility. As demand for these sheets grows, understanding their capabilities, applications, and benefits enhances one's ability to make informed purchasing decisions.

Renowned for their durability, stainless steel mesh sheets stand out by providing long-lasting solutions in environments that demand robust material performance. Constructed from high-quality stainless steel, these sheets can withstand harsh conditions, including exposure to moisture and a variety of chemicals, without succumbing to rust or degradation. This resilience makes them ideal for a wide range of applications, from industrial to architectural uses.

In industrial settings, stainless steel mesh sheets are prized for their strength and durability. They serve critical functions in industries such as petrochemical, pharmaceutical, and food processing. In these contexts, the mesh sheets are often used for filtration, sieving, and separation purposes. Their resistance to corrosion and temperature variations ensures that they maintain structural integrity and performance, safeguarding against contamination and ensuring that operations run smoothly.

Architecturally, stainless steel mesh sheets provide both functional and aesthetic benefits. They are increasingly utilized in contemporary design for facades, cladding, and interior designs. Architects and designers opt for these sheets not just because of their durability, but also because they offer a sleek and modern appearance. They allow light and air to pass through, creating a visually pleasing effect while also serving the practical purpose of shade and ventilation.

stainless steel mesh sheets

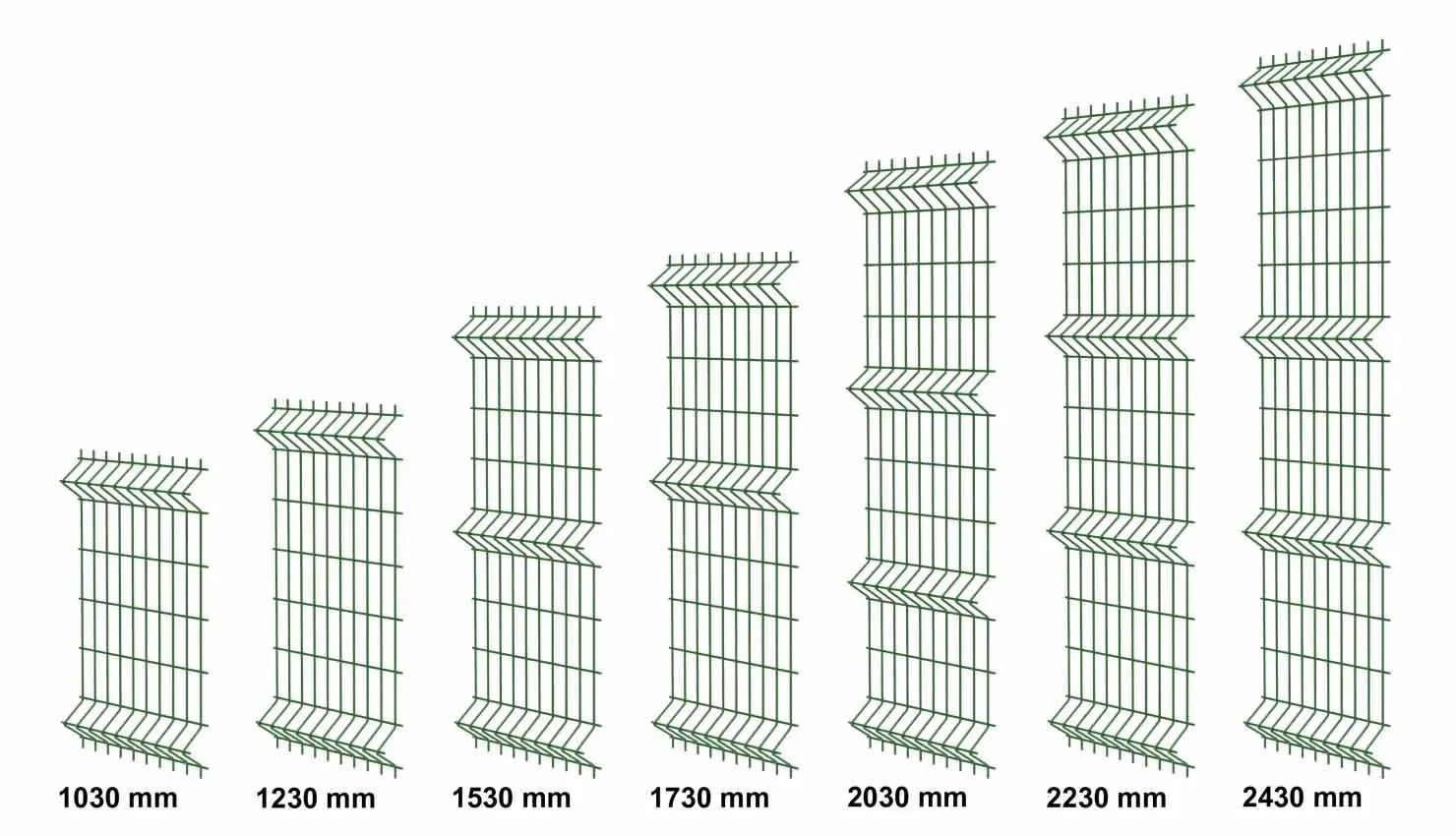

Choosing the right type of stainless steel mesh sheet depends on the specific requirements of the application. Experts recommend considering factors such as mesh size, wire diameter, and weave style. The mesh size determines the size of particles that can pass through, making it crucial for filtration purposes. Wire diameter affects the strength and flexibility of the mesh, influencing how it will perform under stress. The weave style can vary from plain to twill or Dutch, with each style offering unique benefits in terms of strength and filtration efficiency.

The authority in stainless steel mesh sheet manufacturing lies in factories that adhere to stringent quality control processes and industry standards. Certification and compliance with international standards such as ISO and ASTM are markers of trustworthiness, assuring customers of the product’s quality and performance. When sourcing stainless steel mesh sheets, it is advisable to opt for suppliers who can provide documentation and test results, ensuring that the mesh meets the specific requirements necessary for the intended use.

Real-world experiences of businesses utilizing stainless steel mesh sheets illustrate their value. A case in point is a beverage company that significantly improved its filtration process efficiency by replacing traditional filters with stainless steel mesh. The switch not only enhanced the clarity of their product but also reduced maintenance costs and downtime, exemplifying the sheets' practical benefits.

In conclusion, stainless steel mesh sheets are indispensable in both industrial and aesthetic applications due to their unmatched durability, flexibility, and functionality. An understanding of their properties and applications, guided by expert advice, ensures that businesses and designers alike can leverage these materials to their maximum potential. Trusting in reputable manufacturers and adhering to quality standards ensures that the advantages of stainless steel mesh sheets are fully realized, paving the way for innovations across various sectors.