Navigating the myriad options for effective drainage solutions can be overwhelming. In the realm of high-performance drainage systems, stainless steel gully gratings stand out as a top-notch product for various commercial and residential applications. They offer a rare combination of practical benefits and aesthetic appeal, setting a benchmark for industry standards.

Stainless steel gully gratings manifest an unparalleled level of expertise in design and functionality. Their robust nature supports a broad spectrum of environmental factors; whether it's heavy rain, abrasive materials, or chemical exposure, these gratings consistently deliver. The alloy's intrinsic resistance to corrosion makes it an ideal choice for drainage solutions in areas that experience frequent exposure to moisture or toxic substances. In environments like industrial kitchens or chemical processing plants, where corrosive agents are prevalent, stainless steel gully gratings demonstrate superior durability.

Authoritativeness in stainless steel gully gratings is marked by their compliance with international standards such as ISO 9001. This compliance is not merely a formality but an affirmation of the gratings' reliable performance and quality control. Users can trust that they meet rigorous safety and structural standards, providing peace of mind in demanding operational conditions. The manufacturing process involves precise engineering and metallurgical prowess, ensuring that each grating fits perfectly and performs optimally.

A significant aspect of these gratings' trustworthiness is their sustained performance over time. Unlike other materials that may degrade or warp, stainless steel maintains its integrity under significant load pressures and fluctuating temperatures. This resilience means lower maintenance costs and less frequent replacements, offering long-term financial advantages. Facilities managers and homeowners can trust in the longevity and consistent performance of stainless steel gratings, resulting in fewer disruptions and reliable drainage operations.

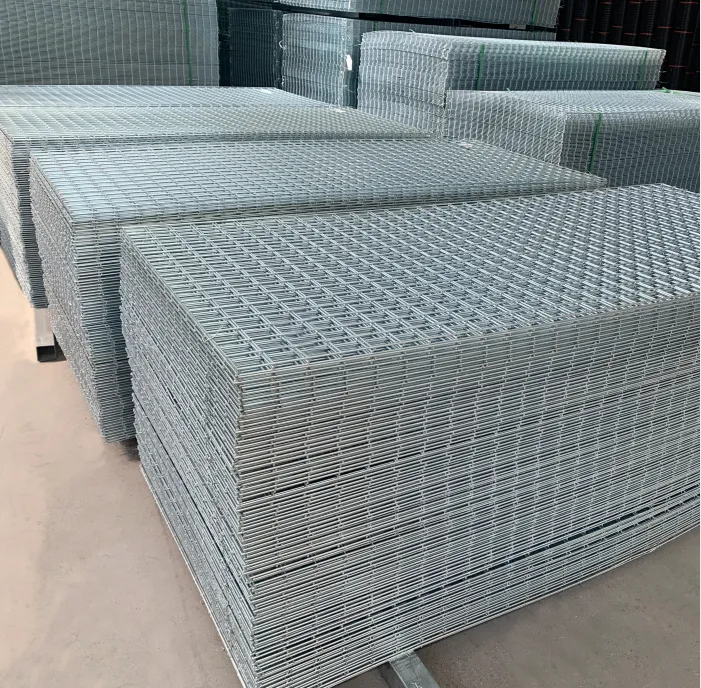

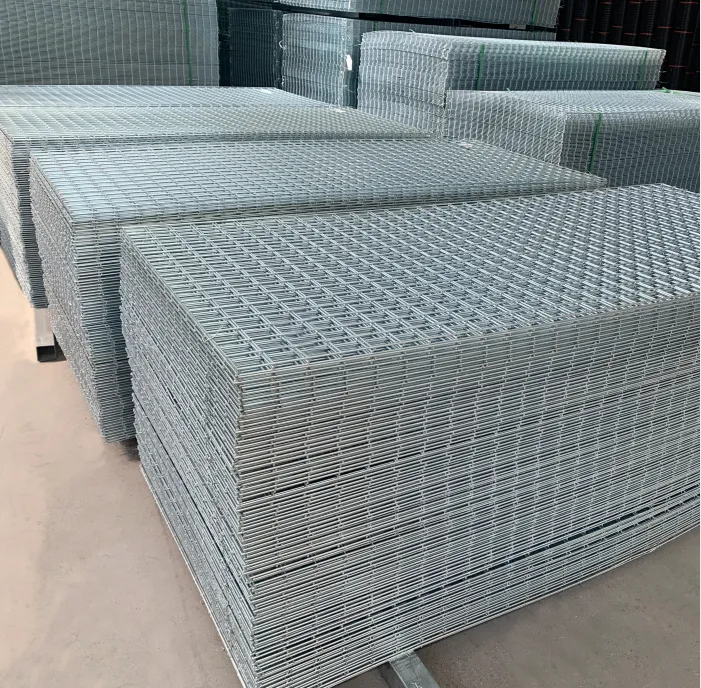

stainless steel gully grating

On an experiential level, the installation and maintenance of stainless steel gully gratings is hassle-free. Their lightweight design, despite their strength, facilitates easier handling and positioning, making installation quicker and more efficient. They are available in various sizes and can be customized to meet specific project requirements, thereby improving the overall customer experience. Users praise their low-maintenance nature, noting that debris removal and cleaning operations are significantly simplified as compared to traditional grating materials.

In terms of expertise, professionals tout stainless steel for its unmatched adaptability across diverse sectors—from healthcare facilities, where hygiene is paramount, to public spaces and transportation infrastructure where safety and durability are non-negotiable. Subject-matter experts advocate for stainless steel as part of sustainable building practices due to its full recyclability, contributing to eco-friendly construction goals.

Moreover, aesthetically, stainless steel gully gratings complement modern architectural designs with their sleek and clean lines. They can blend seamlessly into contemporary environments, enhancing the visual appeal while providing essential drainage capabilities. This dual benefit appeals to architects and designers aiming for both functionality and style.

In conclusion, stainless steel gully gratings define a new standard in drainage solutions, offering unmatched performance, safety, and longevity. Their expert design, backed by authoritative quality standards, ensures they meet and exceed the demands of various industries. By investing in stainless steel gratings, stakeholders are not only leveraging a product of proven expertise but also contributing to sustainable practices that prioritize long-term efficacy and environmental preservation.