(stainless steel stucco lath)

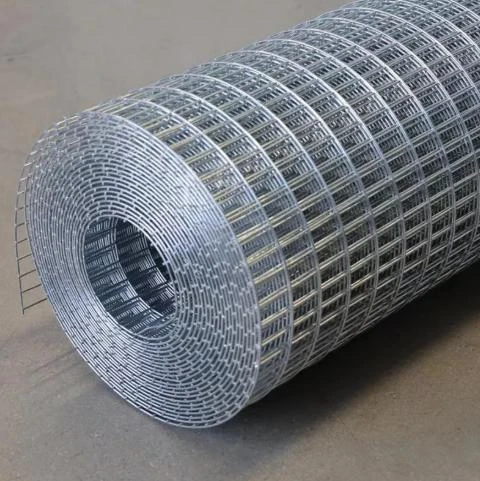

Over the past decade, construction standards for exterior finishing have evolved rapidly, demanding higher durability, performance, and sustainability. Among the most crucial components supporting this evolution is stainless steel stucco lath

. Its emerging dominance globally is a result of superior resistance to corrosion, mechanical strength, and adaptability across a variety of building envelopes. According to 2023 market research, the global demand for metal lath has surged by 7.8% annually, with stainless steel varieties leading due to their longevity in harsh environments. As architects and contractors increasingly prioritize lifecycle value and fire resistance, stainless steel stucco lath is becoming a staple in both commercial and high-end residential projects.

Expanded metal lath for stucco is engineered to facilitate the optimal bonding of plaster while ensuring structural support and stability. The unique process of slitting and expanding galvanized or stainless steel produces an array of diamonds or mesh openings, allowing for even plaster retention. Unlike traditional galvanized alternatives, stainless steel mesh delivers improved performance, offering tensile strengths over 520 MPa and ensuring zero rust, even in extreme humidity or coastal regions. Modern variants feature enhanced load distribution capabilities, with mesh weights optimized between 1.2–2.2 kg/m², aligning with both residential retrofits and commercial facade cladding. These technical advancements not only reduce maintenance costs but also ensure compliance with ASTM C847 and BS EN 13658 specifications for exterior plaster base materials.

When considering the performance of metal mesh for stucco, several metrics distinguish stainless steel options from traditional lath products. Field tests demonstrate that stainless steel lath maintains 98% of its original strength over a 20-year period, compared to 65% for galvanized alternatives under identical environmental exposure. Furthermore, fire resistance classification (A1 per EN 13501-1) and resistance to cyclic salt-spray conditions ensure that stainless steel lath outperforms other meshes in even the most aggressive settings. Durability is further quantified by accelerated aging studies, where stainless steel meshes exhibit no significant deformation or loss of integrity after 2000 hours of exposure to moisture and alkali agents—a critical factor for both facade and infrastructure applications. Building code compliance is further reinforced through third-party certifications, integrating safety, environmental, and design flexibility parameters for modern construction.

To assist specifiers and procurement teams in choosing the right mesh system, a table highlighting key characteristics across leading manufacturers is provided below.

| Manufacturer | Material Type | Thickness (mm) | Mesh Size | Tensile Strength (MPa) | Corrosion Resistance | Certifications | Warranty (Years) |

|---|---|---|---|---|---|---|---|

| SS Lathworks Inc. | Stainless Steel 304 | 0.50 | 13 x 30 mm | 520 | Excellent (No Rust 2000h) | ASTM C847, EN 13658 | 30 |

| Duramesh Industries | Galvanized Steel | 0.45 | 12 x 26 mm | 370 | Moderate (Minor Corrosion 500h) | UL Listed | 10 |

| Global Lath Solutions | Stainless Steel 316 | 0.60 | 18 x 38 mm | 575 | Excellent (No Rust 3000h) | CSA A179, ASTM C1780 | 35 |

| MeshMaster Corp. | Galvanized Expanded Metal | 0.38 | 14 x 33 mm | 330 | Fair (Light Rust 300h) | ISO 9001 | 8 |

As indicated, stainless steel varieties consistently outperform in strength, resistance and warranty, ensuring better long-term value despite higher upfront costs.

Diverse construction scenarios require a breadth of stainless steel lath customization. Manufacturers offer bespoke solutions addressing project-specific needs, from mesh thickness and dimensions to stainless steel grades (e.g., 304, 316L, 430) and special surface treatments for enhanced plaster key. Custom roll lengths up to 50 meters, varied expanded mesh orientations, and pre-formed corner and angle lath streamline installation on complex architectural features such as arches, soffits, and curved surfaces. Additionally, edge reinforcement, integral fastening strips, or powder-coated finishes can be specified for unique project demands such as hospitals, seafront developments, or high-rise facades. Collaboration with suppliers during the design phase ensures efficient logistics, waste reduction, and adherence to sustainability benchmarks such as LEED or BREEAM certification. For projects sensitive to thermal conductivity or requiring non-magnetic properties, duplex or austenitic steel alloys can be tailored for optimal performance without compromising safety or visual appeal.

Real-world implementation of expanded metal lath for stucco demonstrates its versatility and performance in diverse sectors. In commercial high-rise developments across New York and London, stainless steel stucco lath was integral to cladding systems that withstood wind loads exceeding 70 kPa and maintained façade integrity after three winters of freeze-thaw cycling. Restoration of historical facades in Mediterranean climates benefited from its ability to resist salt-induced corrosion, with site inspection reports citing no visible degradation after five years in service. Additionally, in the construction of coastal public infrastructure (e.g., sea walls, transit stations), custom mesh solutions enabled rapid installation over non-uniform substrates, reducing labor hours by an average of 18% compared to welded wire or panel systems. Educational and healthcare facilities value the fireproof and allergen-free profile of stainless steel lath, supporting healthy environments and consistent compliance with local codes. These examples reinforce the material’s adaptability to creative architectural designs, rigorous environmental challenges, and strict regulatory frameworks.

The use of stainless steel stucco lath stands out as a best-practice solution for advanced façade construction, offering a compelling combination of durability, technical innovation, and environmental responsibility. Its proven superiority over galvanized alternatives is clear in both data and long-term field performance, as illustrated by extended warranties, third-party certifications, and robust application results. As the construction industry continues to raise expectations for efficiency, fire safety, and sustainability, investment in stainless steel lath delivers measurable value across project lifecycles. In summary, selecting high-grade stainless steel stucco lath and customized metal mesh for stucco ensures maximum performance, peace of mind, and compliance with modern building standards.

(stainless steel stucco lath)

RELATED PRODUCTS