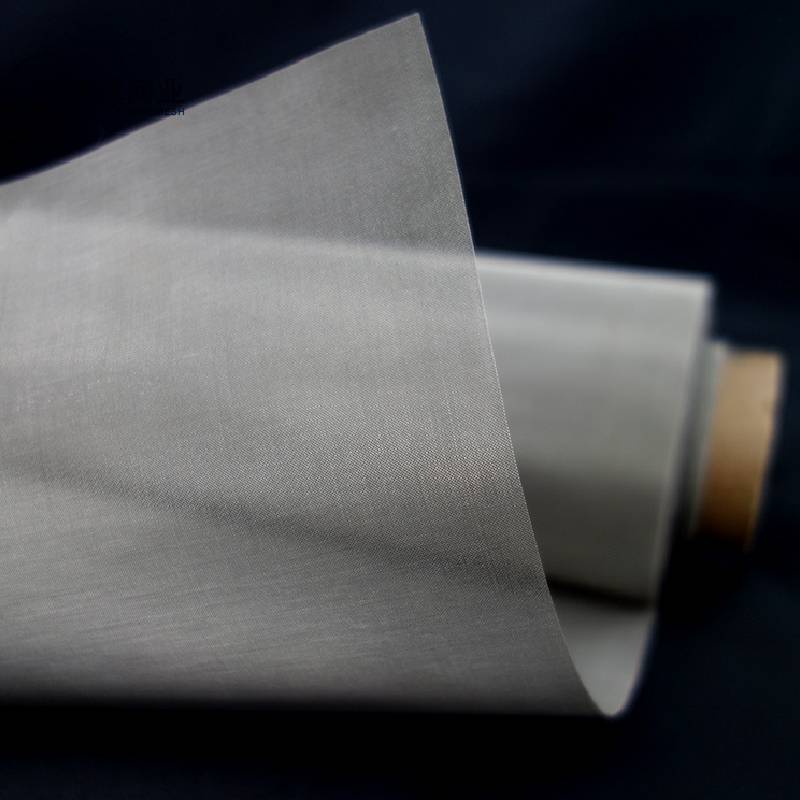

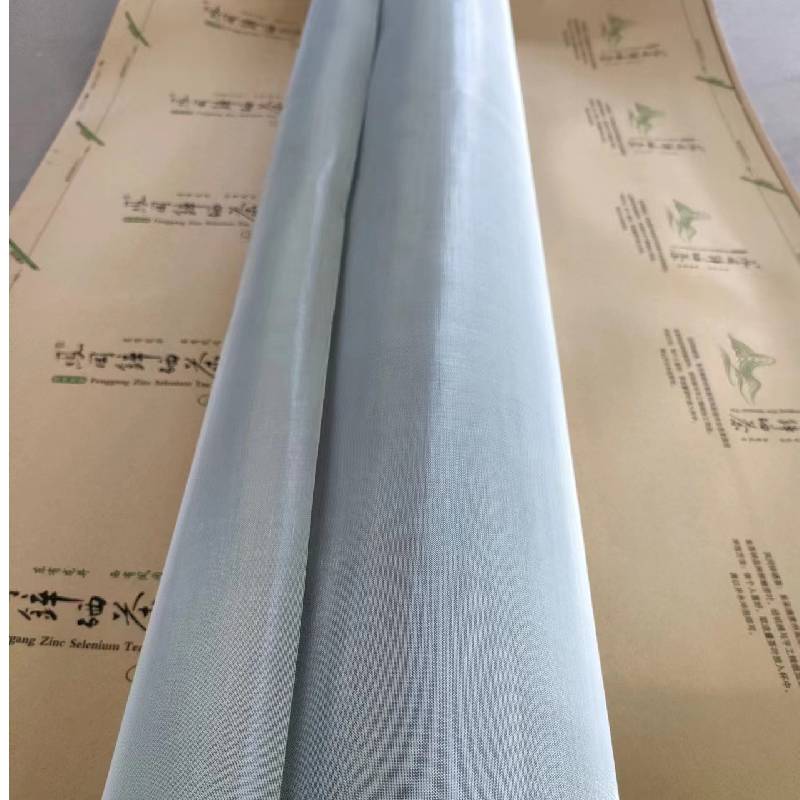

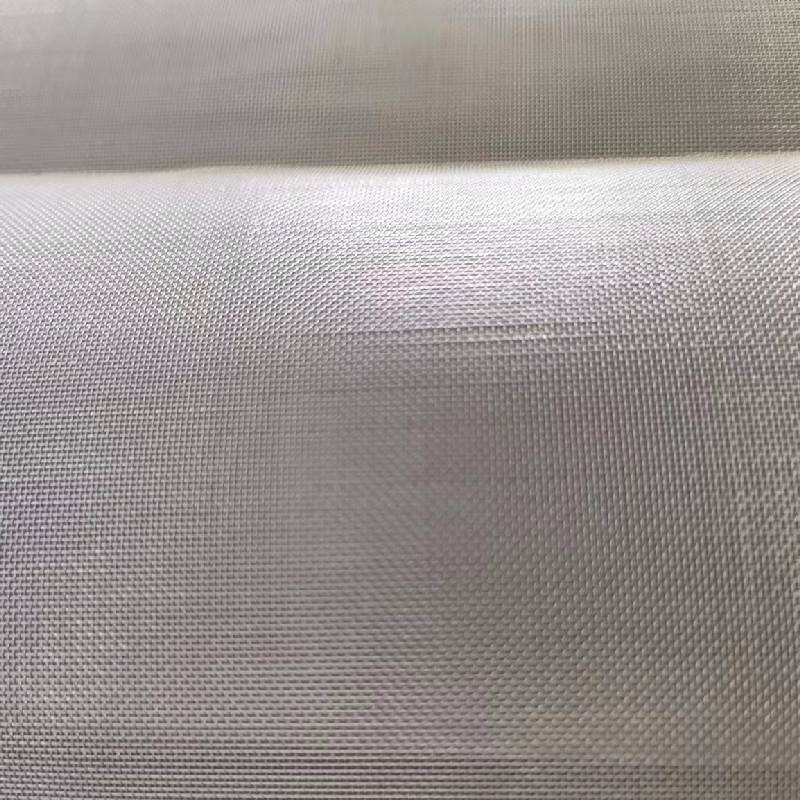

If you spend enough time around fabrication shops and job sites, you notice something: people rely on Square Wire Mesh more than they talk about it. It’s the quiet backbone in screens, guards, sieving, ventilation, and a dozen other places where strength, openness, and predictable aperture matter. To be honest, I’ve seen it save projects where perforated sheet would have warped budgets or airflow. Here’s the current state of play, with a few shop-floor observations thrown in.

| Parameter | Common Options | Notes |

|---|---|---|

| Material | Low-carbon steel, SS304/316, galvanized (pre or post) | 316 for chloride-rich environments |

| Mesh count (per inch) | 2–80 | Higher counts for fine screening |

| Wire diameter | 0.3–2.0 mm ≈ | Trade-off: strength vs. open area |

| Aperture/opening | 0.2–12 mm ≈ | ASTM E2016/ISO 9044 tolerances |

| Weave | Plain, twill (less common) | Plain is the workhorse |

| Roll width/length | 0.9–1.5 m wide, 15–30 m long | Custom cuts available |

Material selection → wire drawing → annealing (as needed) → precision weaving on automatic looms → flattening/leveling → cutting/rolling → surface finishing (galvanizing, passivation) → inspection and packaging.

Advantages many customers mention: consistent aperture, easy formability, repairable sections, and fair pricing compared to perforated alternatives.

| Vendor | Origin | Certifications | Lead Time | Customization |

|---|---|---|---|---|

| Tike Metal (Square Wire Mesh) | East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui, Hebei | ISO 9001; conforms to ASTM E2016/ISO 9044 | 7–15 days typical | Cut-to-size, coatings, SS316 |

| Regional Fabricator A | Domestic | ISO 9001 (varies) | 10–20 days | Limited weave range |

| Import Broker B | Mixed | Supplier-dependent | 15–35 days | Spec-by-spec, MOQ higher |

For Square Wire Mesh guarding, go 3–4 mm aperture with ≥1.2 mm wire to resist denting. For sieving, confirm aperture with a certificate to ISO 9044. Edge treatments (framed, hemmed) cut install time—worth it, honestly.

Documentation available on request: material certs (EN 10204 3.1), aperture/mesh count reports, salt-spray results, and RoHS/REACH declarations.

RELATED PRODUCTS