A Field Note on Square wire mesh: What’s Changing, What Matters

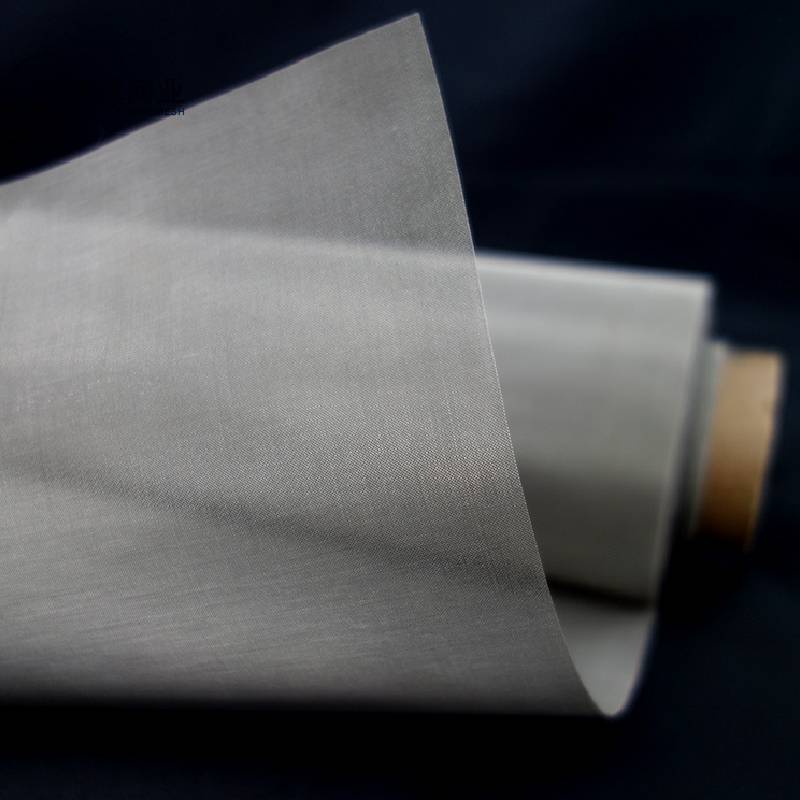

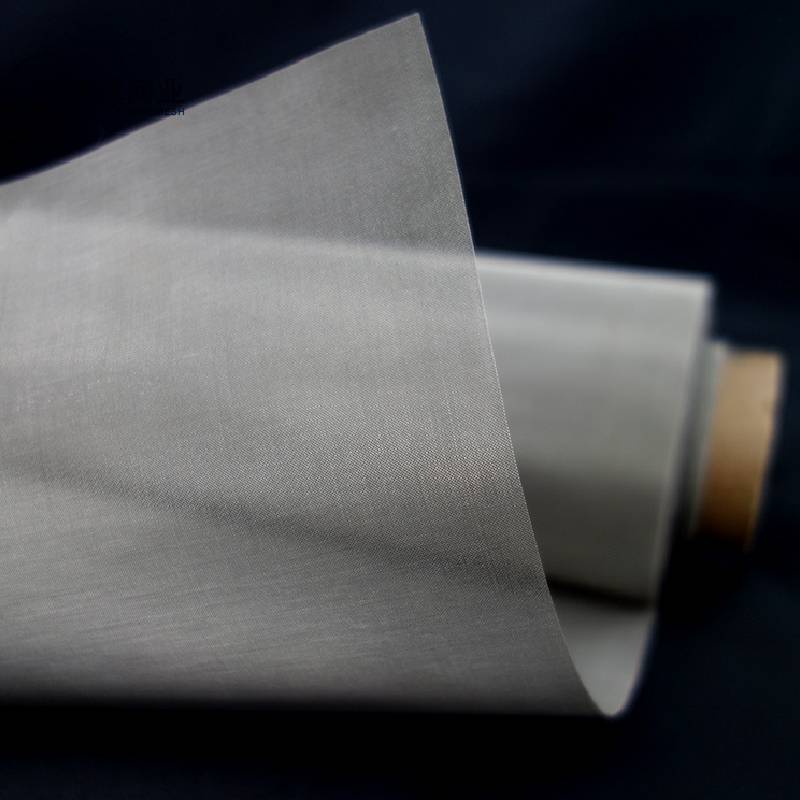

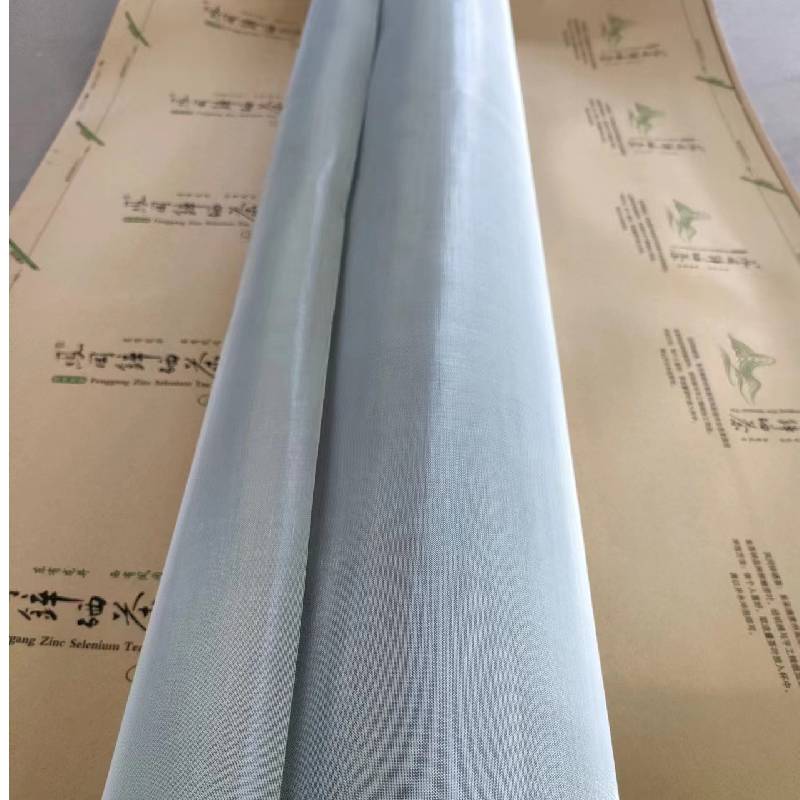

If you spend enough time around fabrication shops and job sites, you notice patterns. And lately, demand for Square wire mesh has been quietly climbing—driven by tighter tolerances in filtration, more corrosion-aware construction specs, and, to be honest, a new wave of buyers who expect fast customization without paying aerospace prices.

What’s trending

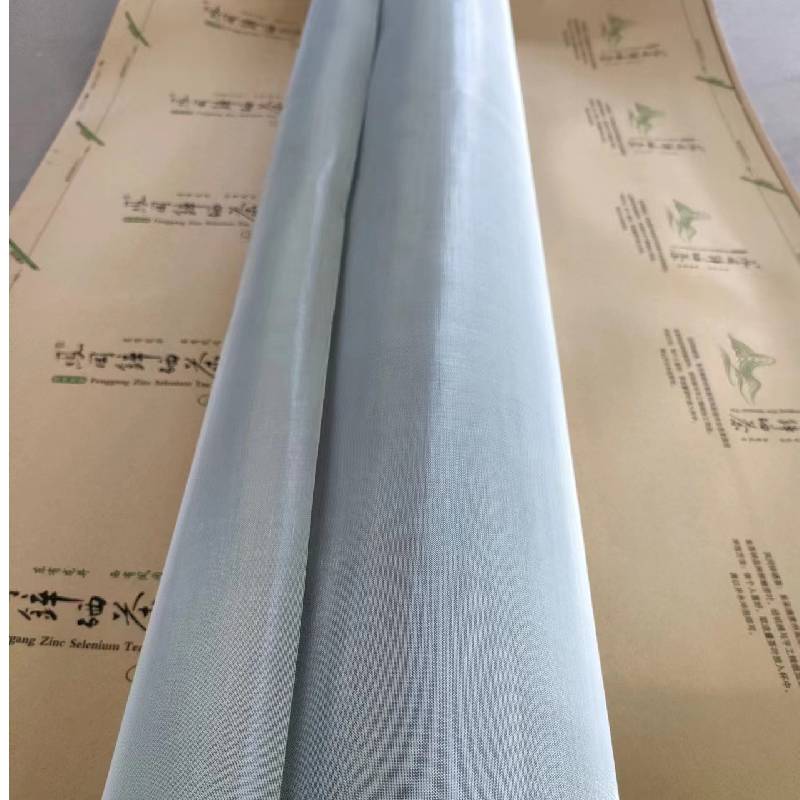

- Materials: 304/316 stainless is displacing low-carbon steel in coastal and food-adjacent projects.

- Finishes: Heavy zinc (around 230 g/m²) and epoxy-coated meshes for HVAC and coastal fencing.

- Traceability: Lot-level MTRs and ASTM/ISO conformance reports are now table stakes, not “nice to have.”

Quick spec snapshot

| Mesh count (per inch) |

Wire dia (mm) |

Opening (mm) ≈ |

Material |

Finish |

Width (m) |

| 2 × 2 |

2.0 |

10.7 |

Low-carbon steel |

Galv. after weave |

1.0–2.0 |

| 10 × 10 |

0.6 |

1.94 |

SS 304 |

Plain |

1.0–1.5 |

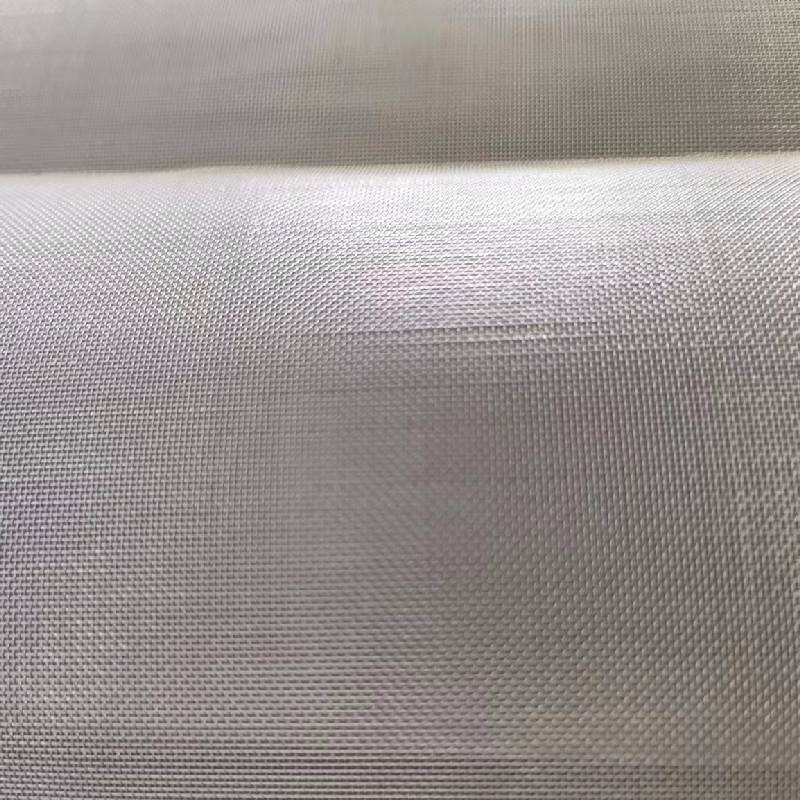

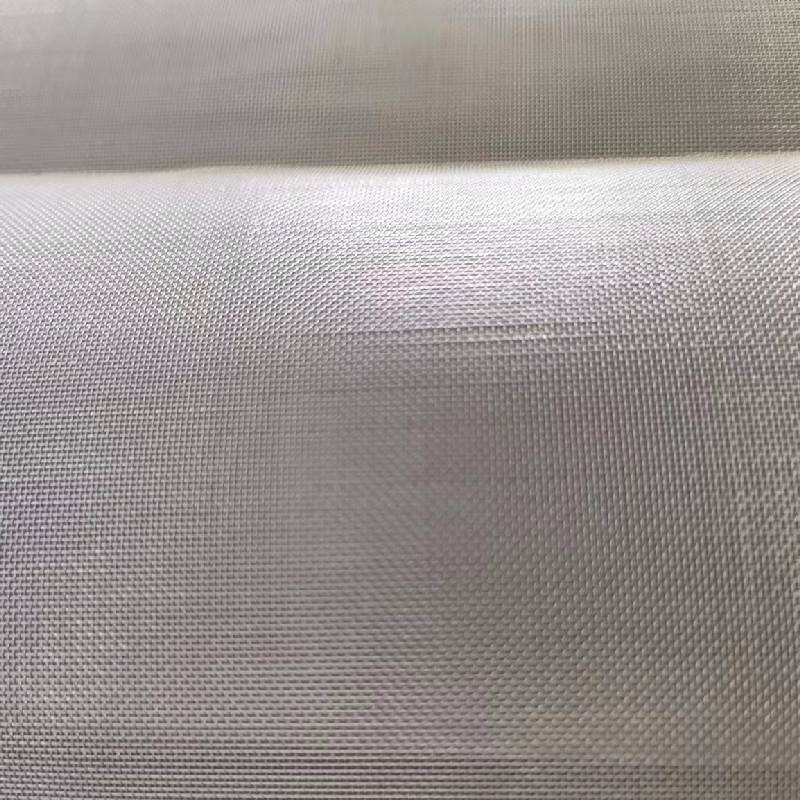

| 20 × 20 |

0.4 |

0.87 |

SS 316 |

Pickled |

1.0 |

Tolerances per ASTM E2016; real-world use may vary.

Process flow and QA

- Materials: Low-carbon steel (ASTM A641), SS wire (ASTM A580) with MTRs and heat numbers.

- Methods: Plain weave (most common), intermediate crimp for large openings, roll widths up to 2 m.

- Testing: Mesh count per 25.4 mm, wire diameter micrometer checks, tensile ≥ 550–900 MPa (grade-dependent), zinc mass gravimetric, salt-spray to ISO 9227.

- Service life: Galv. 5–15 yrs; SS304 ≈ 10–20 yrs; SS316 ≈ 15–25 yrs in coastal/chemical—assuming routine cleaning.

- Standards: ASTM E2016, ISO 9044 terminology and tolerances; food-contact projects often ask for FDA/EC conformance on upstream steel.

Where Square wire mesh shines

- Construction: Facades, safety guards, plaster reinforcement.

- Filtration/Screening: Pre-filters, grading, sifting in aggregates and grain.

- HVAC: Intake screens with epoxy or hot-dip coatings.

- Food and chem: SS316 baskets, trays, and resistant screens.

Vendor comparison (shortlist)

| Vendor |

Lead time |

Certs |

QC scope |

Customization |

Price level |

| Tike Metal (Hebei) |

7–15 days |

ISO 9001; MTRs |

ASTM E2016 full-lot reports |

Width, alloy, opening, frames |

Mid |

| Regional fabricator |

2–4 weeks |

Varies |

Spot checks |

Cut-to-size only |

Mid–High |

| Generic importer |

Stock only |

Limited |

Basic inspection |

Minimal |

Low |

Real-world notes, tests, and feedback

A coastal HVAC client reported 3× filter pre-screen life after switching to epoxy-coated Square wire mesh (10×10, 0.6 mm wire). In quarry screening, 2×2 galv.-after-weave reduced tear-outs by ~18% versus pre-galv., according to their maintenance logs.

- Test snippet: 316 mesh, 20×20, tensile avg. 740 MPa; opening deviation ≤ ±3% (n=50 samples).

- Salt spray (ISO 9227): Galv. A-class, red rust onset ≈ 240–360 h, depending on coating mass.

- Customer sentiment: “predictable flatness and fewer burrs”—which, frankly, saves fingers and time.

Customization and origin

Custom roll widths (to 2 m), cut panels, framed screens, and alloy swaps (304/316/low-carbon) are routine. Origin matters for logistics and traceability: produced in the East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province—an area, I might add, that’s been weaving mesh long before it was trendy.

Why pick Square wire mesh over alternatives?

- Predictable aperture geometry for grading and airflow.

- Repairable: easy to cut, frame, and replace in the field.

- Cost-effective vs. perforated plate at comparable open area.

Citations

- ASTM E2016/E2016M – Standard Specification for Industrial Wire Cloth.

- ISO 9044 – Industrial wire screens and woven wire cloth — Technical requirements and tests.

- ASTM A580/A580M – Standard Specification for Stainless Steel Wire.

- ASTM A641/A641M – Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire.