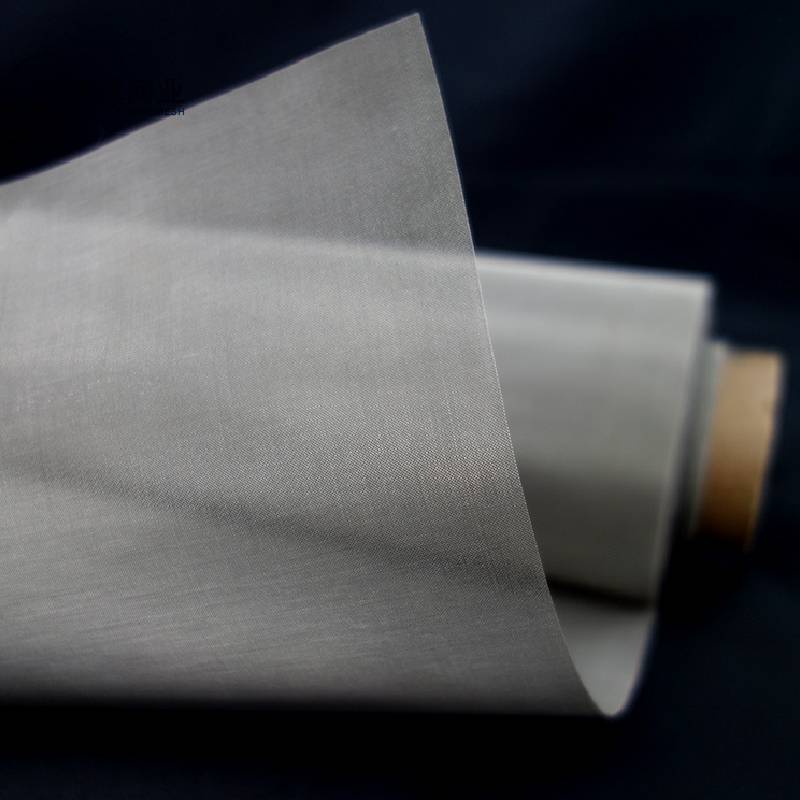

If you spend enough time in factories (guilty), you notice the unsung parts that simply have to work. Square wire mesh is exactly that kind of component—predictable, fixable, and, when sourced right, surprisingly elegant. Tikemetal produces it at scale out of the East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province. It’s a mouthful, but the supply chain knows the address by heart.

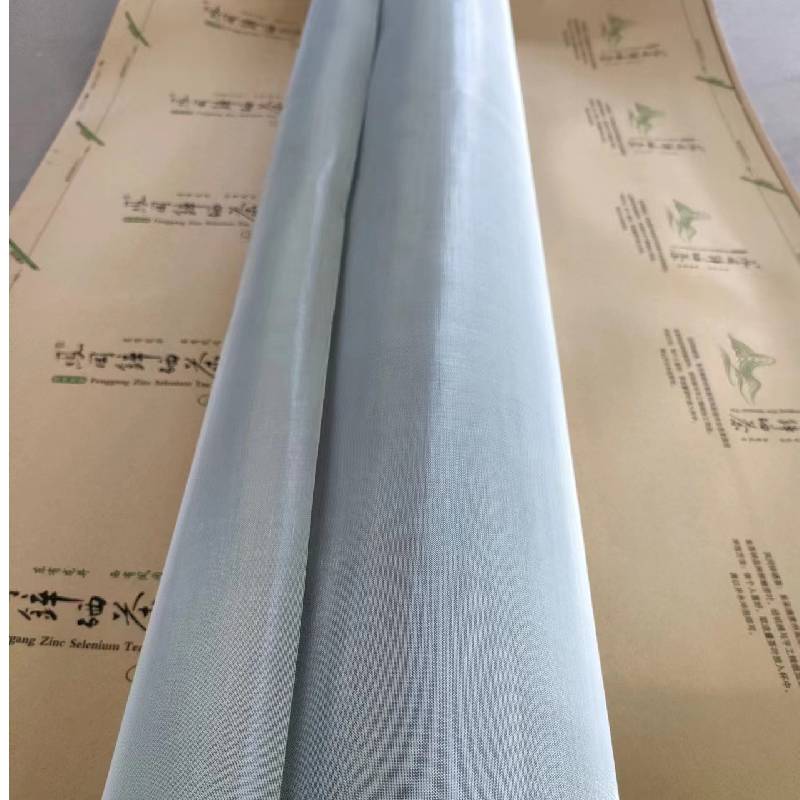

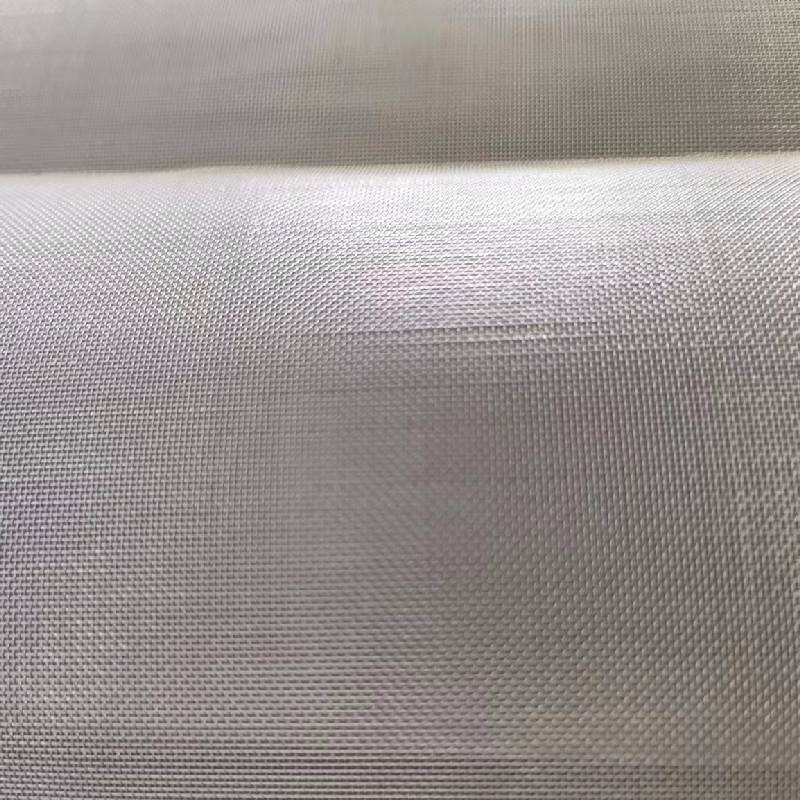

Industry buyers have shifted toward narrower tolerances, cleaner edges, and traceable metallurgy. Stainless (304/316) demand is up in food and battery plants; low-carbon steel still rules for screens and guards. Galvanized and epoxy-coated options are trending for coastal installs. Many customers say the best upgrade has simply been flatter, tension-stable rolls—less rework on the line.

| Mesh (per inch) | Wire dia (mm) | Aperture (mm) ≈ | Open area ≈ | Material | Weave | Roll width |

|---|---|---|---|---|---|---|

| 4 | 1.2 | 5.15 | 68% | Low-carbon, Galv. | Plain | 1.0–1.5 m |

| 8 | 0.6 | 2.58 | 73% | SS304/316 | Plain | 1.0–1.2 m |

| 10 | 0.5 | 2.04 | ≈72% | SS304 | Plain/Twill | 1.0 m |

| 20 | 0.3 | 0.97 | ≈59% | SS316 | Plain | 1.0 m |

Tolerances per ASTM E2016 / ISO 9044; real-world use may vary.

Recent lot test (10 mesh, 0.50 mm SS304): wire dia 0.50±0.02 mm; aperture 2.05±0.05 mm; tensile 720 MPa; flatness <3 mm wave over 1 m. Operators told me installation was “plug-and-run.”

Case snippets—A craft brewery swapped laser-perf for Square wire mesh in a lauter tun and cut cleaning time by ~18%. A quarry in NSW reported fewer blinding events after switching to a slightly larger aperture (8→6 mesh wasn’t the fix; wire polish was).

| Vendor | Origin | Certs | Lead time | Customization | QC docs | Price |

|---|---|---|---|---|---|---|

| Tikemetal | Hebei, China | ISO 9001; RoHS/REACH | 7–15 days | Aperture, alloys, edges, coatings | ASTM/ISO report set | $$ (value) |

| Regional Trader | Mixed | Varies | 10–25 days | Limited | Basic COA | $–$$ |

| OEM Brand | EU/US | ISO 9001/14001 | 15–30 days | High | Full PPAP-like | $$$ |

Customization: cut-to-size panels, framed edges, hemmed safety edges, annealed wire for forming, passivated stainless, epoxy or powder-coat colors. MOQ usually one roll; samples available.

Final thought: with Square wire mesh, the value isn’t just the metal—it’s the tolerance discipline and consistency that save labor later. Sounds boring; saves budgets.

RELATED PRODUCTS