Square Wire Mesh is a key solution in the building materials industry, specifically within metal material and Wire mesh products. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

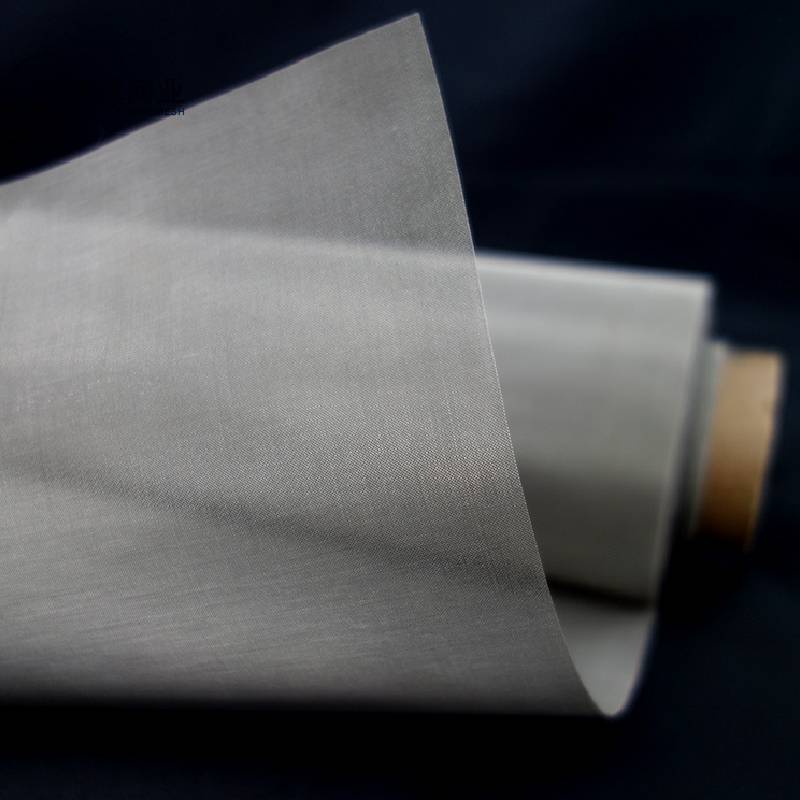

Square Wire Mesh is a precision-woven or welded grid featuring uniform square openings and consistent wire diameters. Within building materials and metal material categories, it delivers reliable aperture control, airflow, visibility, and mechanical support—making it indispensable in screening, guarding, infill panels, and filtration. SHENZHOU TIKE METAL CO., LTD. manufactures Square Wire Mesh in common alloys such as low-carbon steel, hot-dip galvanized steel, and stainless steels (e.g., 304/316) to match corrosion and hygiene requirements across industrial and architectural environments. Typical specifications cover wire diameters from fine to medium gauges and a wide range of mesh counts, enabling targeted selection by open area, strength, and weight per square meter. Tight dimensional tolerance and flatness ensure consistent performance in downstream fabrication, whether the mesh is cut-to-size, framed, or formed. In a recent logistics and machinery guarding rollout, Square Wire Mesh helped improve safety and ventilation while simplifying inspection access. From plant upgrades to new-build infrastructure, buyers value the balance of durability, light transmission, and cost efficiency. With robust production controls and responsive customization, SHENZHOU TIKE METAL CO., LTD. is a reliable partner for B2B decision makers seeking dependable quality and on-time delivery.

In the Wire mesh products category, Square Wire Mesh excels in both industrial and architectural roles. Industrial uses include sieving and grading of aggregates, machine guarding, racking and cage systems, ventilation panels, and partitioning. In construction and architecture, it serves as stair and balcony infill, plaster reinforcement, façade screening, and pest-proof ventilation covers. Key advantages include aperture accuracy for predictable flow or particle control, good rigidity-to-weight ratio for structural infill, and excellent cut-and-form compatibility for fast onsite fitting. When corrosion resistance is critical—such as coastal projects, food processing, or high-humidity plants—stainless steel grades deliver long service life. For cost-sensitive environments, galvanized and low-carbon steel mesh offer dependable performance with protective coatings. SHENZHOU TIKE METAL CO., LTD. supports OEM and contractor needs with custom widths, panelization, framed assemblies, and edge treatments (e.g., hemmed or banded edges) to streamline installation and reduce rework. Consistent coil-to-panel flatness and aperture uniformity reduce snagging and improve aesthetics—important in public-facing railings and façades. Combined with responsive lead times and professional packing, these attributes make Square Wire Mesh a versatile, specification-friendly choice for procurement teams and project managers.

Total cost of ownership for Square Wire Mesh includes material selection, fabrication, installation, maintenance, and eventual replacement. Stainless steel typically yields the longest lifecycle in corrosive settings, lowering replacement frequency and downtime. Galvanized steel offers a strong balance of upfront cost and corrosion resistance for warehouses, guarding, and general building uses. SHENZHOU TIKE METAL CO., LTD. helps optimize ROI by aligning mesh count, wire diameter, and alloy to the environment and load case—minimizing over-spec and preventing premature wear. Customers in metal material sectors value consistent flatness and aperture control because they reduce trimming, welding, and alignment time. To simplify upkeep, choose alloys and finishes that match exposure: stainless for moisture/chemicals, galvanized for general outdoor, and painted or powder-coated finishes for added durability or branding. Routine cleaning and inspection of fixings prevent localized corrosion and ensure long-term safety. End users report smoother installation when panels are pre-cut and edge-treated, while robust packaging reduces transport damage and site waste. With dependable lead times and stable quality, Square Wire Mesh from SHENZHOU TIKE METAL CO., LTD. delivers predictable lifecycle costs—an essential factor for procurement and project controls.

Sustainability priorities are reshaping metal material choices across building materials. Steel-based Square Wire Mesh is fully recyclable and compatible with circular-economy goals, while long service life reduces embodied impacts from replacements. Demand is rising for products that support ventilation, daylighting, and passive safety—areas where mesh is naturally strong. Growing attention to worker safety and machine guarding reinforces the need for uniform, durable barriers with predictable apertures. At the same time, prefab and modular construction favor mesh panels that arrive cut-to-size and ready to install, reducing onsite waste and accelerating schedules. SHENZHOU TIKE METAL CO., LTD. aligns with these trends through material optimization, efficient yields, and packaging options that minimize damage and waste. The company’s capability to supply custom dimensions and surface finishes supports architects and contractors aiming for performance and aesthetic targets without over-specifying materials. By focusing on lifespan, recyclability, and designs that deliver airflow and visibility, Square Wire Mesh contributes to healthier, more efficient buildings and industrial facilities. Forward-looking procurement teams can leverage these attributes to meet sustainability objectives while controlling costs and maintaining robust safety standards.

From screening and guarding to architectural infill, Square Wire Mesh delivers the strength, aperture control, and versatility that building materials and metal material buyers require. With material options tailored to environment and load, it offers dependable performance and attractive lifecycle costs. SHENZHOU TIKE METAL CO., LTD. stands out for consistent quality, customization, and responsive service—key factors for project success and supply chain reliability. Ready to specify or source mesh that meets your exact standards? Contact us: email: info@tikemetal.com. Visit our website: https://www.tikemetal.com. Explore the product page for technical details and inquiries: https://www.tikemetal.com/square-wire-mesh.html.

RELATED PRODUCTS