I’ve walked more factory aisles than I care to admit, and, to be honest, the hum of wire-drawing lines still feels oddly calming. In Hebei’s production corridor—specifically the origin at East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City—this category keeps evolving. Demand is steady, quality controls are tighter, and customization has gone from “nice-to-have” to baseline. Actually, many customers say the latest lots are flatter, cleaner, and more consistent than five years ago.

Below are typical configurations for Square wire mesh—woven (plain weave) and welded options. Common size wires and mesh:

| Mesh (per inch) | Wire Dia (mm) | Aperture (mm) ≈ | Open Area ≈ | Material | Roll/Sheet |

|---|---|---|---|---|---|

| 2 × 2 | 1.60 | 11.10 | ≈ 77% | Low-carbon / HDG | Sheets |

| 4 × 4 | 1.00 | 5.35 | ≈ 74% | SS304 / SS316 | Rolls & Sheets |

| 8 × 8 | 0.50 | 2.68 | ≈ 70% | SS304 | Rolls |

| 10 × 10 | 0.40 | 2.14 | ≈ 67% | SS304 / SS316 | Rolls |

Tolerances per ASTM E2016 / ISO 9044; real-world use may vary by grade and finish.

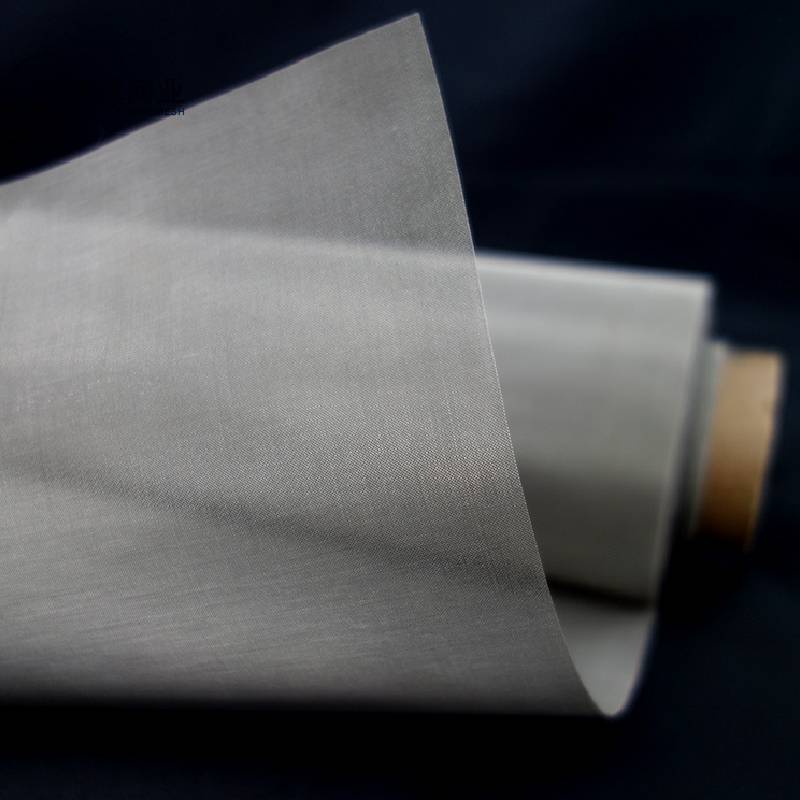

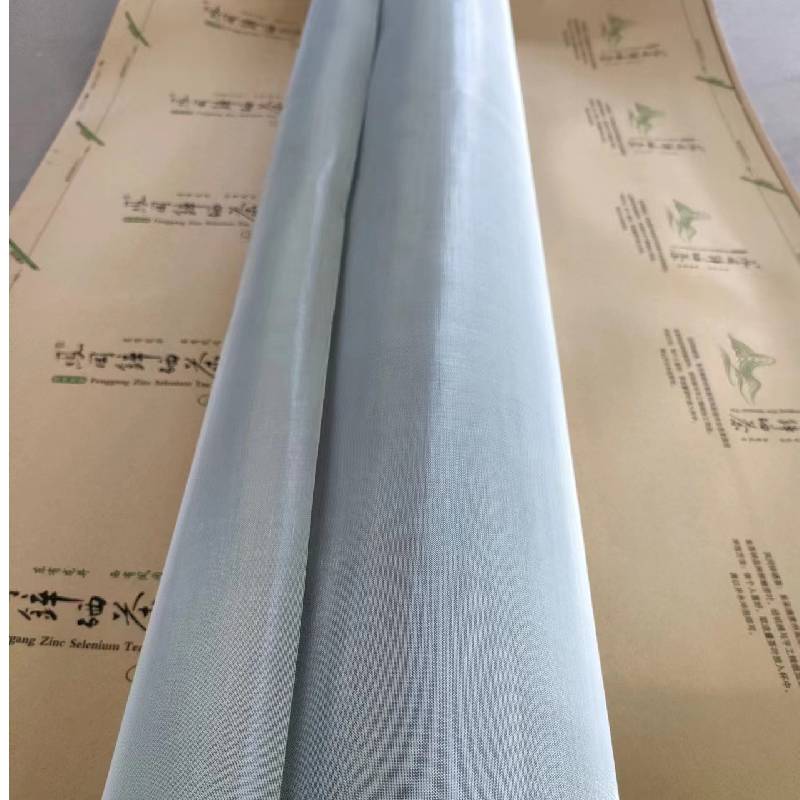

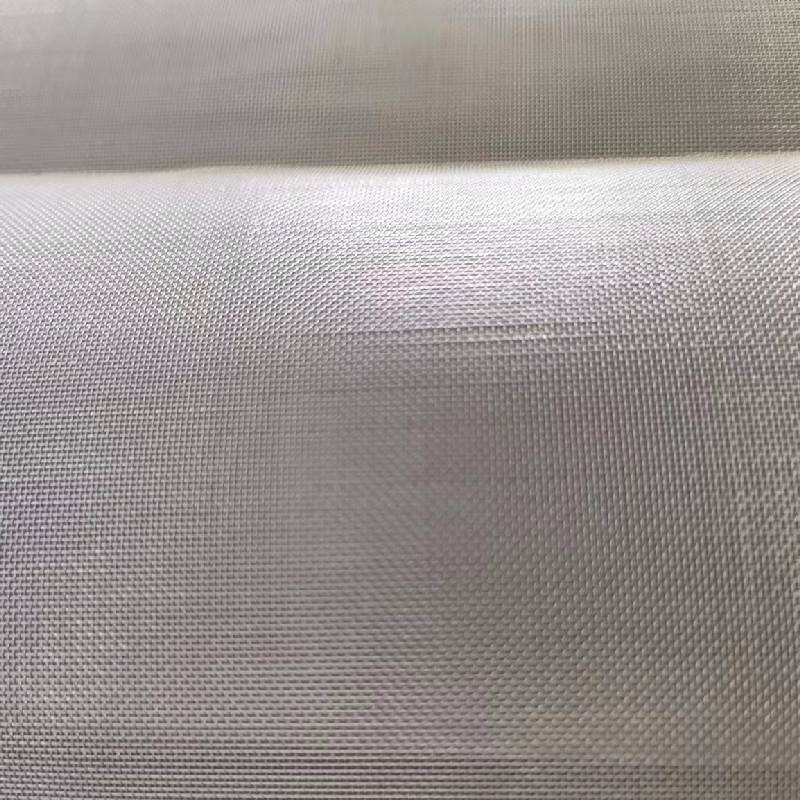

Square wire mesh typically comes in two flavors: woven (plain weave for square apertures) and welded (resistance-welded at each intersection).

Service life: indoors SS ≈ 10–20 years; coastal outdoor SS316 ≈ 8–15; galvanized ≈ 2–8 depending on thickness and exposure.

Advantages of Square wire mesh: consistent opening, high open area for airflow, fast installation, and ample customization.

| Vendor | Lead Time ≈ | MOQ | Customization | Certs |

|---|---|---|---|---|

| Tikemetal (Hebei) | 7–15 days | Low (around 200–500 m²) | Mesh, wire, finish, roll width | ISO 9001; material MTRs |

| Local Fabricator | 3–4 weeks | Medium | Limited range | Varies |

| Trading Company | 2–5 weeks | Medium–High | Depends on mill | On request |

Options include mesh count (2–80), wire dia (0.20–2.5 mm), roll width (0.9–1.5 m typical), sheet sizes, edges (selvage, cut), and finishes (passivation, electropolish, HDG, powder-coat for welded). Many buyers also request laser-cut panels—to reduce on-site trimming and waste.

Retail facade, EU: SS316 10×10, electropolished. Flatness improved by 25% after tensioning tweak; install time dropped by ~18% (contractor feedback).

Feed mill screen, LATAM: Welded 4×4 HDG sheets. After ISO 9227 checks (240 h), coatings held; maintenance interval extended from 9 to 14 months.

Customer sentiment? It seems that repeat orders hinge on two things: consistent aperture and quick replacement lead times. Surprisingly simple, but true.

RELATED PRODUCTS