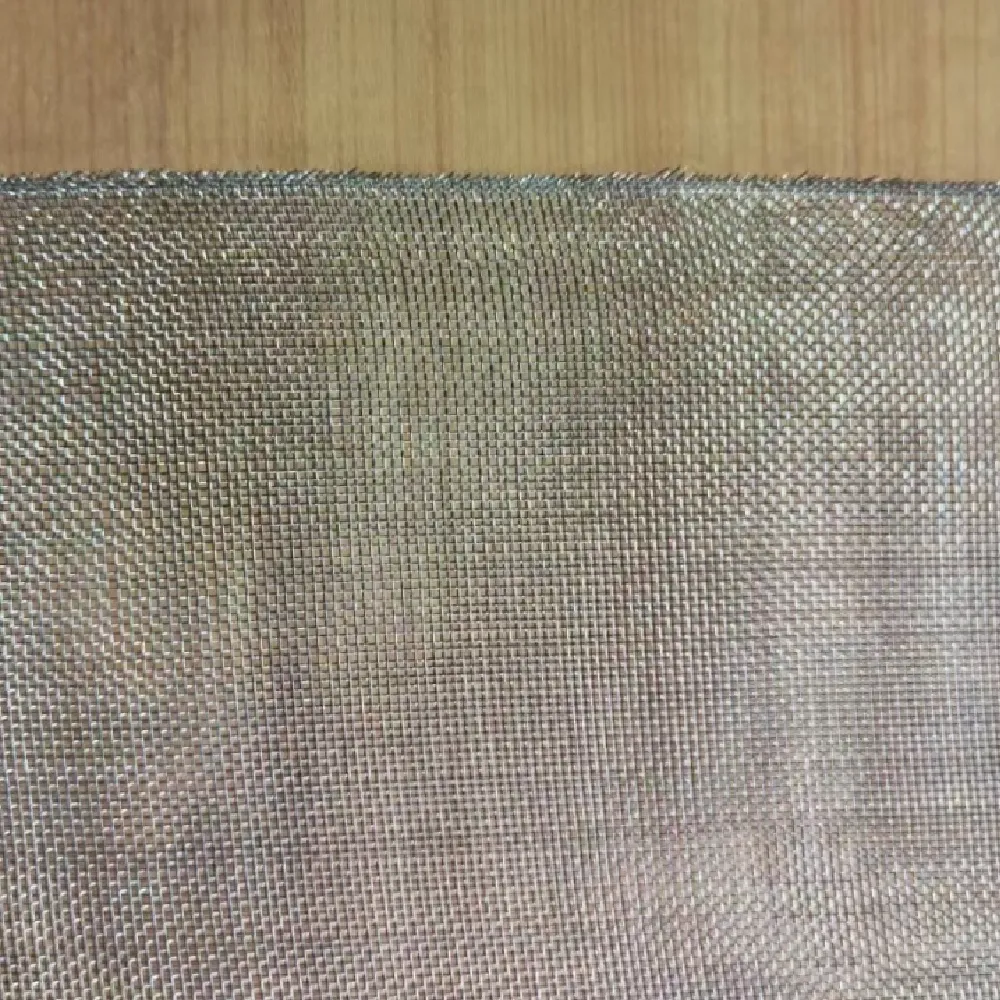

If you’ve worked in screening, filtration, or machine guarding for any length of time, you already know the unsung hero is Square Opening Wire Mesh. It looks simple—grid lines, open area, that’s it—but the devil’s in aperture tolerance and metallurgy. I’ve toured mills across Hebei and the Delta; surprisingly, the biggest differences show up in consistency and post-processing, not just raw material.

Square Opening Wire Mesh is a woven or welded grid with equal apertures in both directions. Common weave types: plain weave (most stable), twill (tighter with finer wires), and welded square mesh for robust panels. Materials range from low-carbon steel (economical) to SS304/SS316 (corrosion resistance), plus galvanized and, occasionally, brass or 2205 duplex for harsh chemistry. Origin for this model: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province.

| Mesh Count (per inch) | Opening (mm) | Wire Ø (mm) | Open Area | Material/Finish | Weave | Service Life≈ |

|---|---|---|---|---|---|---|

| 2 | 10.5 | 1.2 | ≈69% | Low-carbon, hot-dip galvanized | Welded | 8–12 yrs (outdoor) |

| 10 | 1.54 | 0.50 | ≈59% | SS304, mill finish | Plain | 10–15 yrs (indoor) |

| 20 | 0.77 | 0.36 | ≈37% | SS316L, electropolished | Twill | 12–20 yrs (food) |

Real-world use may vary by media, cleaning cycles, and environment.

Materials: SS304/316 (ASTM A580), low-carbon steel (ASTM A641 for zinc-coated), or brass. Methods: wire drawing → annealing (as needed) → weaving on shuttle/rapier looms or resistance welding → flattening → cleaning → passivation/electropolish (stainless) → galvanizing (steel) → shearing and framing. Testing: aperture per ISO 9044; dimensional checks to ASTM E2016; coating mass to ASTM A641; salt spray to ASTM B117. Tensile sampling follows plant SOP; I’ve seen 650–900 MPa on stainless wire in practice.

| Vendor | Lead Time | Certs | MOQ | Customization | QC Method | Price Tier |

|---|---|---|---|---|---|---|

| Tike Metal (Hebei) | 7–15 days | ISO 9001; RoHS | Low (≈50–100 m²) | Cut-to-size, frames, EP finish | ISO 9044 camera gauge | Mid |

| GlobalMesh Co. | 20–30 days | ISO 9001/14001 | Medium | Standard only | Spot checks | Mid-High |

| Local Fab Shop | 2–5 days (stock) | — | Very Low | Cut & weld frames | Manual jig | Variable |

Options: aperture 0.5–50 mm, wire Ø 0.25–3.0 mm, roll widths 1.0–2.5 m, panel frames, passivation/electropolish, powder coating (on welded panels). A recent B117 test ran 240 h on galvanized mesh with Square Opening Wire Mesh panels—white rust under 5% area; SS316L electropolished panels showed no red rust. Many customers say the framed panels arrive flatter than expected, which saves install time.

Certifications on request: ISO 9001, material certs (EN 10204 3.1), RoHS/REACH declarations. To be honest, the paperwork often takes longer than the weaving, but it’s worth it when auditors show up.

Start with media size and open area target; pick material by chemistry (chlorides → SS316L), then choose weave (plain for most, twill for fine). Call out ISO 9044 tolerances, and if hygiene matters, add electropolish. Done.

RELATED PRODUCTS