Perforated metal mesh has emerged as a critical component in modern industrial and architectural applications, offering a unique blend of functionality, durability, and aesthetic appeal. This article delves into the Sheet Plate Punching Mesh product, exploring its key features, technical specifications, and diverse applications. Additionally, we highlight the expertise of its manufacturer, Shenzhou Tike Metal Co., Ltd., and reference authoritative standards from the National Institute of Standards and Technology (NIST) to underscore the product's reliability.

The Sheet Plate Punching Mesh is engineered to meet the demands of modern engineering and design. Its standout features include:

These attributes position the Sheet Plate Punching Mesh as a versatile solution for industries ranging from construction to automotive and beyond.

The Sheet Plate Punching Mesh is available in a wide range of specifications to suit varying requirements. Below is a detailed overview of its parameters:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm–10mm |

| Opening Rate | 5%–80% |

| Aperture | 0.5mm–200mm |

| Hole Distance | 1mm–200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

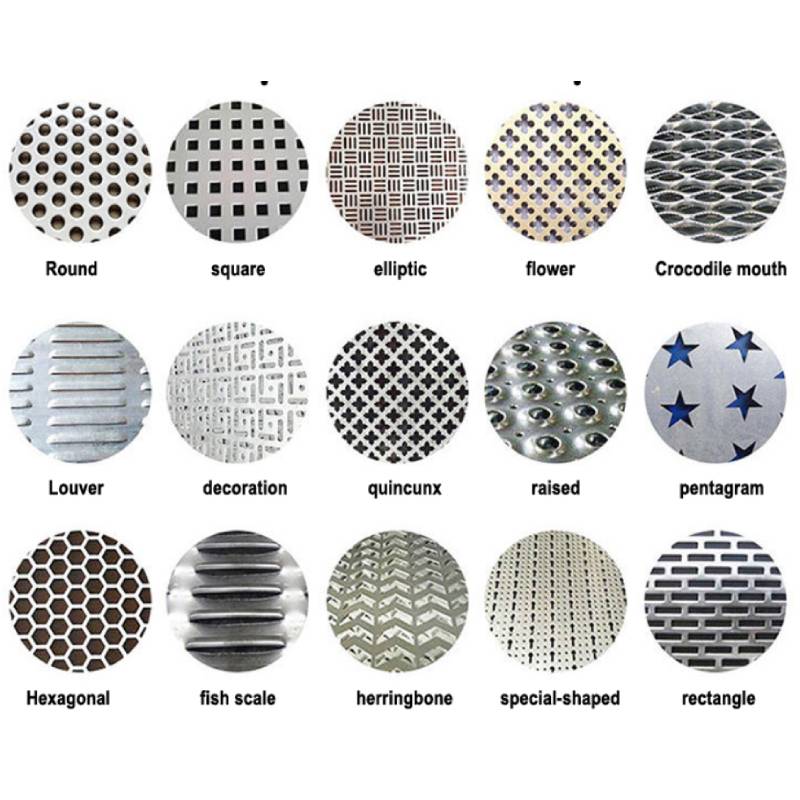

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150–200HB/30–50HB |

| Area Density | 20%–60% |

These specifications ensure the product's adaptability to diverse industrial and architectural needs, from structural support to decorative elements.

The Sheet Plate Punching Mesh is widely used across multiple sectors, including:

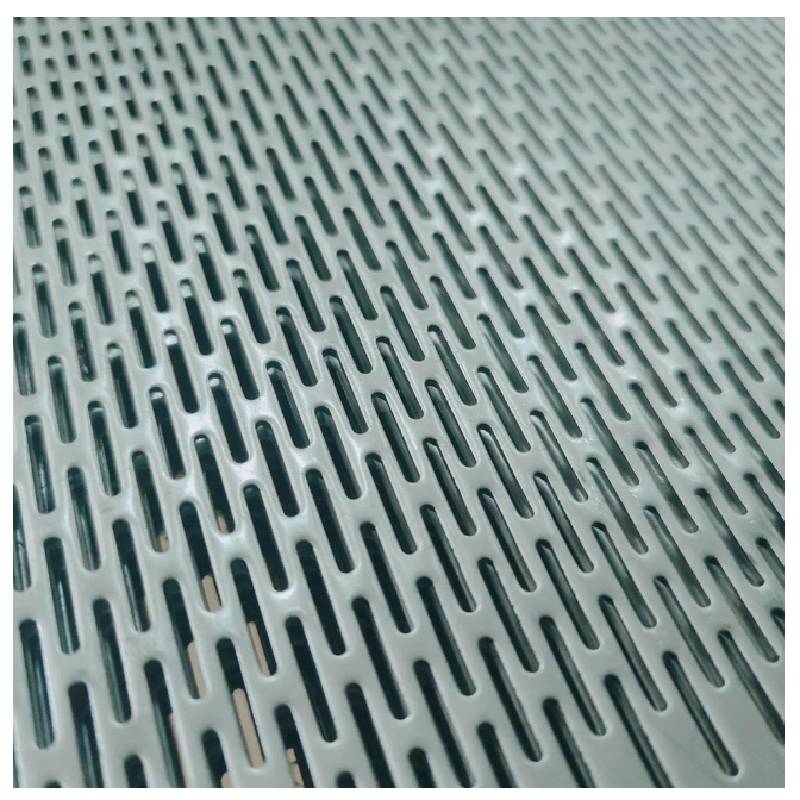

The round hole perforation variant is particularly popular due to its balance of functionality and aesthetics. Below are visual examples of the product in action:

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of metal products, specializing in the production of high-quality perforated metal mesh. With a commitment to innovation and customer satisfaction, the company has established itself as a trusted supplier in the global market. Their expertise in precision engineering ensures that each product meets stringent quality standards, as highlighted by NIST's role in setting benchmarks for industrial materials.

According to NIST, "Standards are essential for ensuring the reliability and interoperability of materials and technologies across industries" [1]. Shenzhou Tike Metal Co., Ltd. adheres to these principles, leveraging advanced manufacturing techniques to deliver products that align with international standards.

The Sheet Plate Punching Mesh exemplifies the synergy between engineering excellence and practical application. Its combination of high performance, customization options, and environmental sustainability makes it a preferred choice for a wide array of applications. As industries continue to evolve, the demand for versatile materials like perforated metal mesh will only grow, driven by the need for efficiency, durability, and innovation.

[1] National Institute of Standards and Technology (NIST). https://www.nist.gov/

RELATED PRODUCTS