Screen mesh stainless steel products are much valued across a variety of industries due to their resilience and efficiency. With a wealth of experience in the industry, I can confidently affirm that stainless steel screen meshes offer unparalleled performance, honed by expert craftsmanship and stringent quality checks.

Stainless steel screen meshes are meticulously crafted using high-grade stainless steel, which ensures remarkable durability and resistance to corrosion. This characteristic proves indispensable, particularly in environments subjected to high stress and corrosive substances, such as chemical plants, water treatment facilities, and food processing units. By resisting rust and degradation, these meshes maintain structural integrity and extend the longevity of the applications they are used in, outperforming traditional mesh materials like aluminum and galvanized steel.

Expertise in the fabrication process contributes to the unmatched quality and effectiveness of screen mesh stainless steel. Using advanced weaving techniques, experts can produce meshes in a variety of configurations, including plain, twill, and Dutch weaves, each serving a specific purpose. For instance, plain weaves are ideal for high-flow and light filtration tasks, whereas twill and Dutch weaves cater to more demanding filtration needs where superior strength and load-bearing capabilities are pivotal.

Screen mesh stainless steel products boast authoritative endorsements across industries. Engineering professionals and industry experts often recommend these products due to their versatility and robustness, qualities that are essential in environments requiring stringent safety and hygiene standards. Their applicability ranges from simple architectural applications to complex industrial processes, underlining the authoritative trust placed on these products.

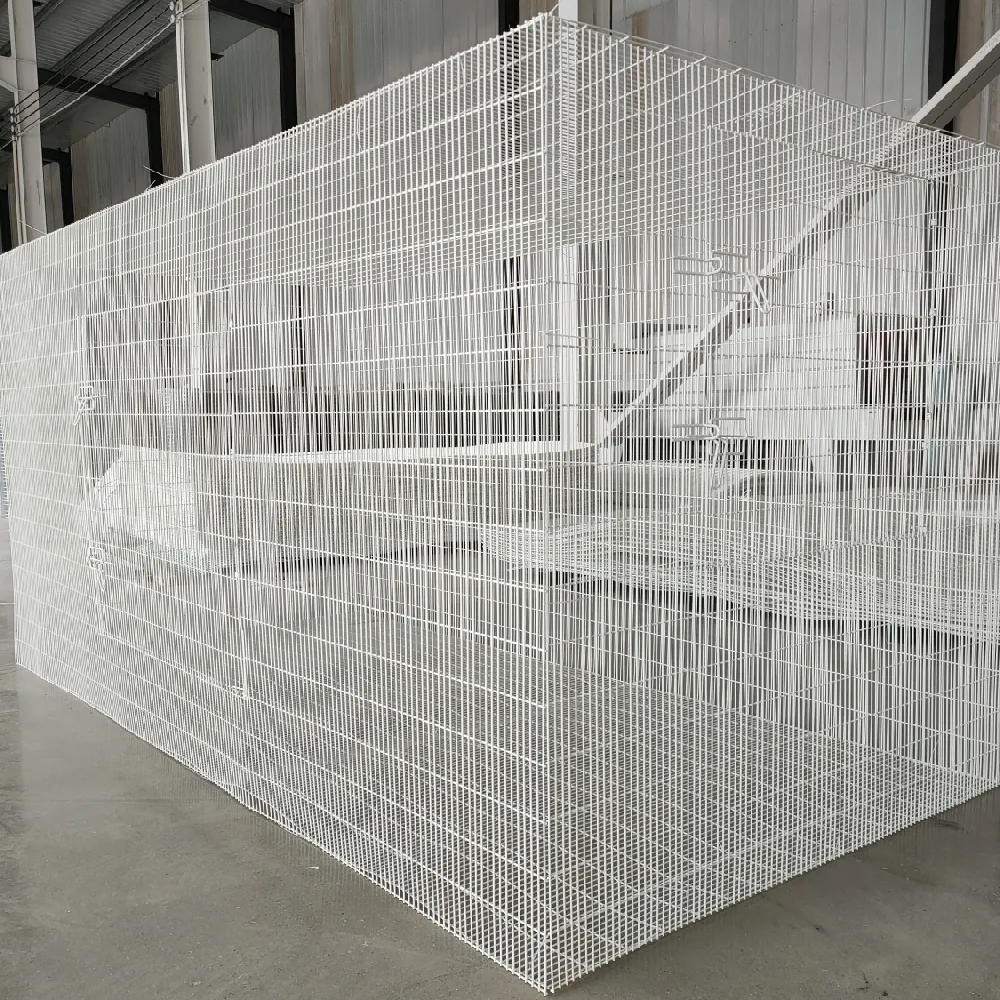

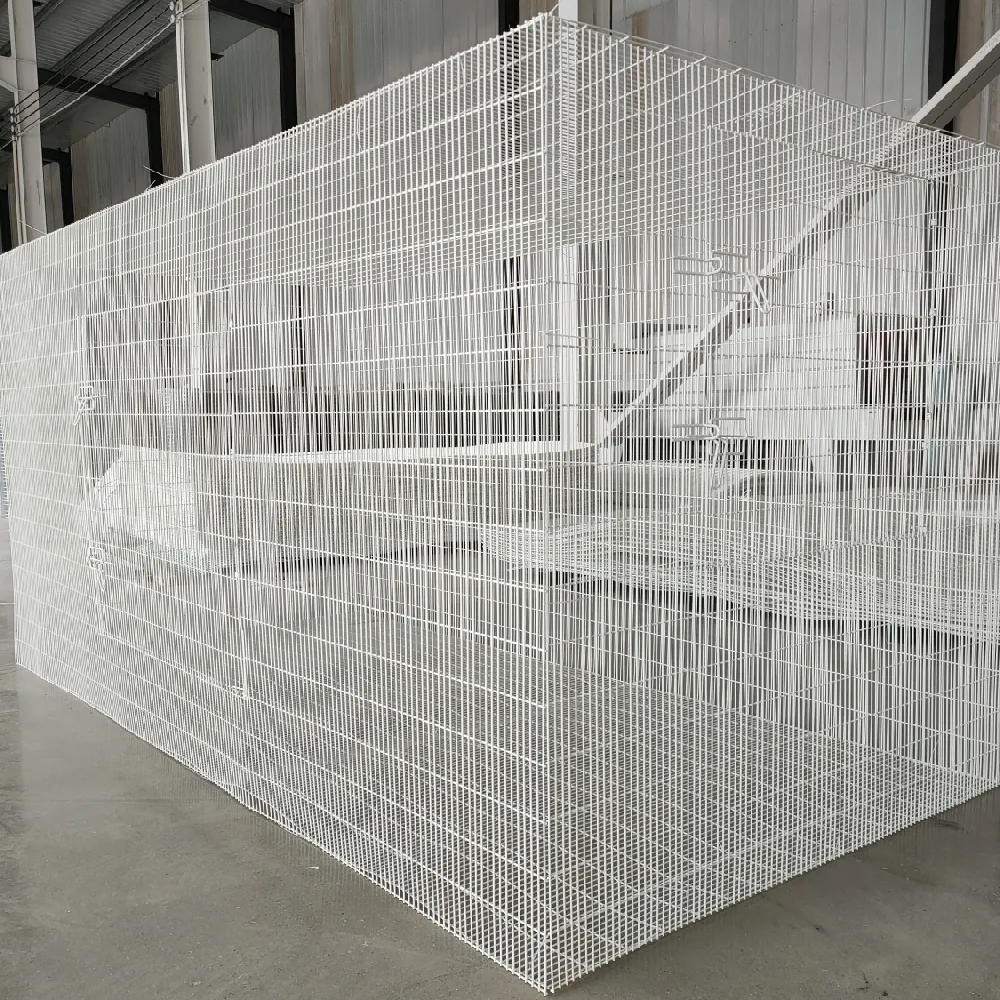

screen mesh stainless steel

A crucial aspect of screen mesh stainless steel's trustworthiness is its compliance with international standards. Adhering to ISO and ASTM standards, these products not only meet but often exceed industry expectations, offering peace of mind to users about the quality and reliability of their investment. This assurance is bolstered by rigorous testing protocols that measure properties such as tensile strength, mesh aperture consistency, and overall product durability.

Additionally, insights from industry insiders frequently highlight the role of screen mesh stainless steel in sustainable practices. Owing to its recyclable nature, stainless steel is an environmentally friendly option that aligns with global sustainability goals. This ecological advantage does not compromise the product's functionality or quality, making it an ideal choice for forward-thinking businesses committed to reducing their environmental impact.

In my extensive experience in evaluating and promoting industry-leading materials, I emphasize the importance of selecting the right mesh specification to meet specific project requirements. Variables such as wire diameter, mesh count, and weave type should be carefully considered to optimize performance and achieve desired outcomes effectively.

Investing in screen mesh stainless steel is a testament to prioritizing quality and longevity. Its ability to withstand extreme conditions while providing reliable performance makes it an invaluable asset across various sectors. Whether for industrial sieving, architectural design, or environmental applications, choosing stainless steel screen meshes guarantees a superior return on investment, ensuring operational excellence and enhancing overall project success.