(rolled cattle fence)

The agricultural industry continually seeks effective and enduring solutions for livestock management and property protection. Among available options, the rolled cattle fence

offers an optimal blend of resilience, adaptability, and ease of installation. Primarily manufactured from galvanized steel wire, these fences are packaged in rolls of variable heights and lengths, providing flexibility for expansive or irregular terrain.

According to the USDA National Agricultural Statistics Service, over 72% of US cattle operations use fencing systems, with galvanized rolled wire fences accounting for roughly 47%. The increasing adoption of rolled systems is propelled by their superior cost efficiency and labor savings, which can reach up to 30% reduction in total installation time compared to panel fencing.

Understanding why this fencing is rapidly becoming the go-to choice for modern ranchers and landowners requires a deeper look into its construction, technological features, and the ways it outperforms longstanding alternatives.

Rolled cattle fences are designed with both productivity and animal safety in mind. Typically, these fences are constructed with high-tensile, galvanized, or zinc-aluminum alloy wires. This enhances their longevity, withstanding environmental pressures such as UV radiation, heavy rainfall, and snow loads. Galvanization levels typically exceed 220g/m2, ensuring up to 20 years of rust-free performance under average conditions.

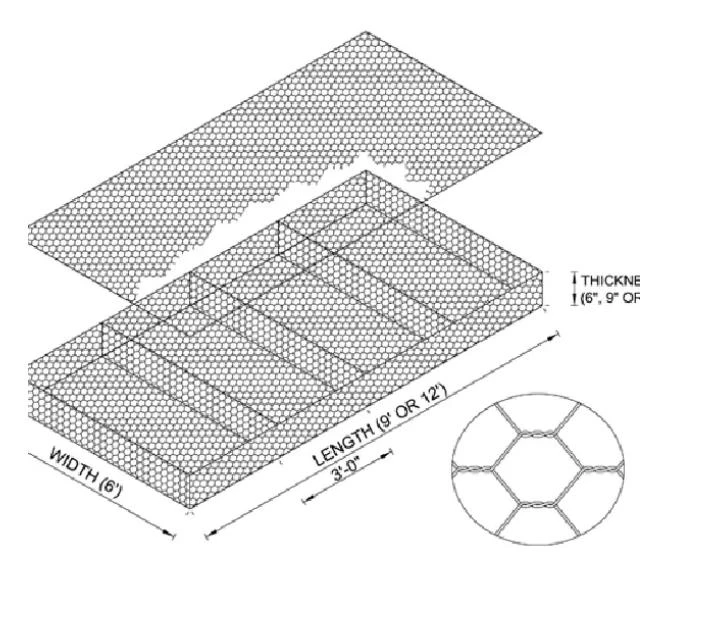

The knots used—fixed knot, hinge joint, or S knot—impart flexibility and strength. Fixed knot systems, for instance, increase tensile strength to over 1,200 N, accommodating impacts from large cattle without permanent deformation. Mesh sizes also vary, with 6", 12", or variable field patterns designed to keep livestock secure while excluding predators.

Additionally, the rolled format allows for rapid mechanical or manual installation, decreasing labor requirements. A crew of two can typically install up to 1,500 meters/day in flat terrain, compared to 800 meters using traditional panel sections. These technical features directly address the operational needs of large and small farms alike.

Selecting the right supplier plays a crucial role in fencing project outcomes. The following table provides a data-based analysis of leading suppliers in terms of material quality, lifecycle, standard roll dimensions, and supply capacity. Data provided is based on 2023 global market surveys and manufacturer disclosures.

| Manufacturer | Wire Spec (Tensile/Coating) | Expected Lifespan (yrs) | Standard Roll Size (ft) | Annual Supply Capacity (Miles) | Warranty (yrs) |

|---|---|---|---|---|---|

| BeefGuard Fencing (USA) | High Tensile, 240g/m2 Zn | 20–25 | 330 x 4, 330 x 6 | 1,700 | 20 |

| AgriDefend (EU) | Galvanized, 200g/m2 ZnAl | 15–18 | 328 x 5, 328 x 8 | 1,200 | 15 |

| MetalTech Ranch (Asia) | Medium Tensile, 180g/m2 Zn | 12–15 | 328 x 4, 328 x 6 | 2,400 | 10 |

| PastureMax (Australia) | High Tensile, 250g/m2 ZnAl | 23–28 | 330 x 5, 330 x 6 | 2,100 | 25 |

Leading brands strongly suggest not only longer product life and enhanced warranties but drastically different supply capacities, which can be vital for large-scale operations. Custom solutions and aftersales service also vary, influencing overall customer satisfaction.

Modern livestock operations are increasingly diverse, requiring tailored fencing solutions for cattle, goats, sheep, and mixed herds. Customization begins with mesh size and configuration: 4", 6", and graduated mesh are common to match specific animal sizes. Wire gauges can be adjusted from 12.5 to 14 gauge, striking a balance between cost and resistance to breach.

For property perimeter security or exclusion of large predators, double bottom wires or smaller lower mesh sizes are favored. Height is also fully customizable, with standard options ranging from 39" up to 96", accommodating everything from calves to mature bulls.

Moreover, finish can be customized: classic hot-dip galvanizing, ZnAl alloy, or even powder coating for unique conditions. Some manufacturers now offer eco-friendly coating options, catering to intensive environmental stewardship programs.

Rapid lead times, private labeling, and co-branding are additional customizable facets. Smart fencing integration—embedding warning signals or fiber optics—is a nascent but growing field for high-value operations.

Selecting between rolled cattle fence, rolled expanded metal, and traditional cattle fence panel fence hinges on unique property or herd demands. The following table illustrates key technical and cost differences:

| Product Type | Tensile Strength (N) | Lifespan (yrs) | Install Speed (m/day) | Avg. Cost per 100m (USD) | Flexibility | Maintenance |

|---|---|---|---|---|---|---|

| Rolled Cattle Fence | 1,200 | 20+ | 1,400–1,800 | $88 | Excellent | Low |

| Rolled Expanded Metal | 950 | 15 | 1,200–1,400 | $110 | Good | Medium |

| Cattle Fence Panel Fence | 1,000 | 15 | 700–900 | $129 | Fair | High |

Rolled cattle fencing stands out for its agility, ease of repair, and lower cost. Expanded metal options are ideal for security fencing but may lack flexibility for undulating terrain. Panel fencing excels in crowding or corral applications, though it is considerably slower and more labor-intensive to deploy.

Field performance consistently reinforces the practical value of rolled cattle fencing. On a 5,200-acre Texas ranch, the switchover from welded panel fencing to galvanized rolls resulted in a 42% reduction in annual maintenance due to decreased warping and breakage. The initial deployment spanned 5 miles in under 4 days with a four-person team.

In Queensland, a commercial cattle station implemented ZnAl-coated fencing—a premier anti-corrosion solution—across coastal marshland, recording less than 1.3% degradation after 7 years, compared to 8.5% for panel fencing in similar conditions.

Mixed farms in Minnesota utilize custom mesh sizing (graduated mesh) for effective control of cattle and sheep. Here, rolled fencing enabled flexible property demarcation and improved predator exclusion, generating positive ROI within 3 years.

The military and wildlife reserve sectors also favor rolled cattle fences for perimeter security, due to rapid install rates and the ability to create obstacle zones without heavy construction equipment. Farmers consistently rank ease of use and adaptability as primary purchase drivers in annual user surveys.

The increasing preference for rolled cattle fence is rooted in its remarkable blend of durability, flexibility, and economic value. Industry data, technical innovation, and practical results all point to its status as a top performer for livestock protection, property management, and security. Compared to traditional panel fencing and even rolled expanded metal, rolled cattle fence offers a compelling proposition—lighter installation burden, longer ROI horizon, and broad applications from agricultural estates to national infrastructure projects.

As manufacturers compete and supply chains evolve, further advances in coatings, mesh technology, and smart integration are set to extend the capabilities of rolled fencing systems. For operations seeking sustainable, reliable solutions, investment in best-in-class rolled cattle fence technology signals a commitment to long-term resilience and efficiency.

(rolled cattle fence)

RELATED PRODUCTS