In the field of geotechnical engineering, reno mattress has emerged as a critical tool for erosion control, slope stabilization, and waterway management, valued for its flat, flexible design and robust performance. A key provider of this solution is SHENZHOU TIKE METAL CO.,LTD, based in Shenzhou with two export departments in Shijiazhuang. Equipped with advanced technology, skilled workers, and expert management, the company specializes in producing reno mattress alongside gabion boxes, leveraging their expertise in welded wire mesh to craft durable, reliable products. As a trusted reno mattress company, they balance precision manufacturing with customization, ensuring their solutions meet diverse project needs. This article explores the role of reno mattress, its relationship with gabions, and how the company’s expertise elevates its applications.

Reno Mattress: Flat Gabion Structures for Slope and Shoreline Protection

Reno mattress is a flat, rectangular gabion structure made from welded or woven wire mesh, designed to be filled with stones or aggregates to form a low-profile, flexible barrier. Unlike traditional gabion boxes (which are taller), its shallow depth (typically 10–30cm) makes it ideal for protecting slopes, riverbeds, and shorelines where horizontal coverage and adaptability to terrain are critical.

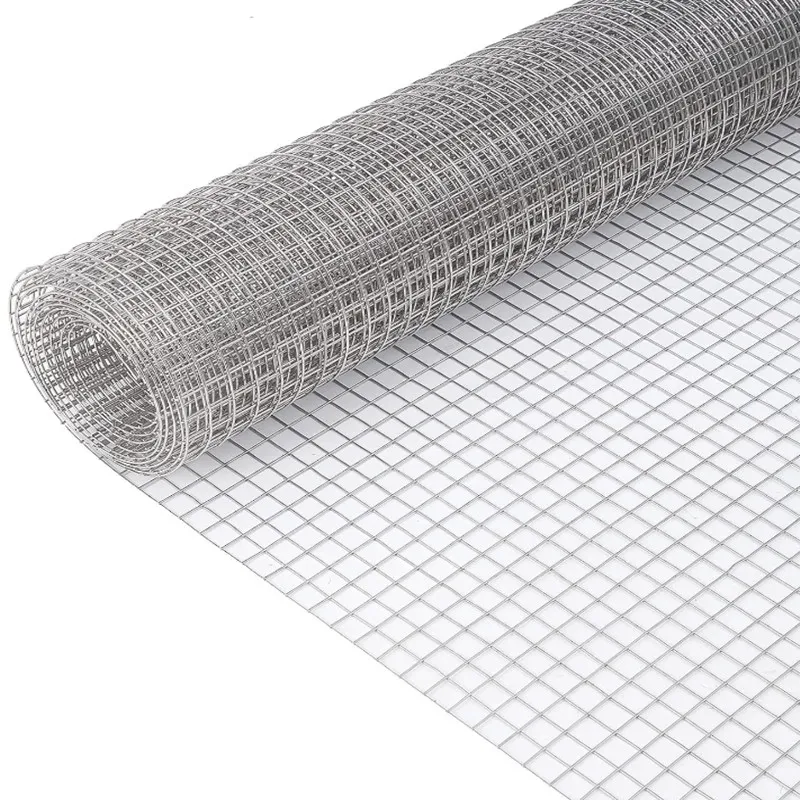

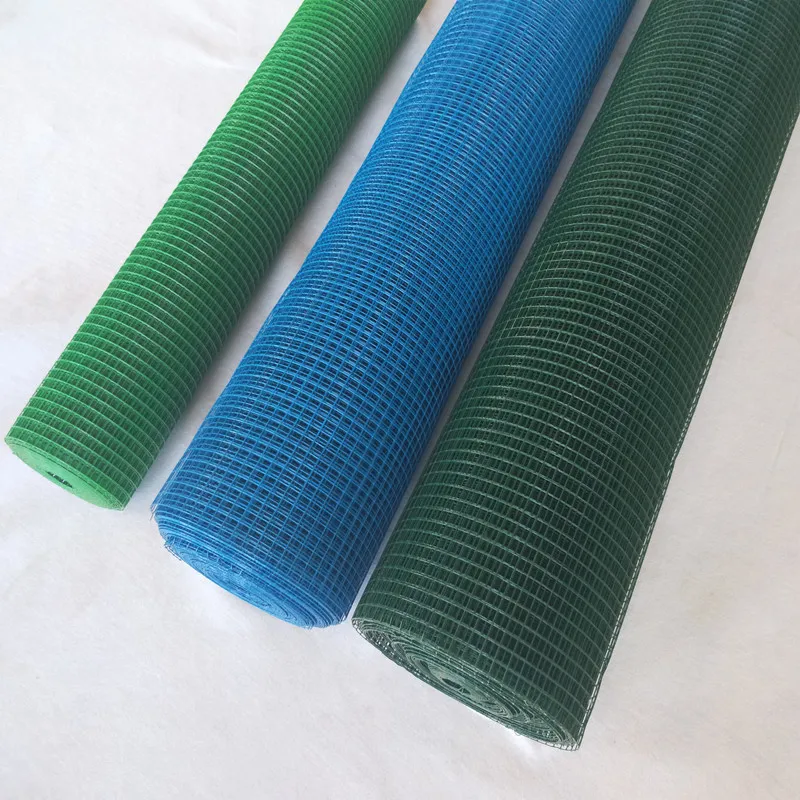

SHENZHOU TIKE METAL CO.,LTD constructs reno mattress using high-tensile low-carbon steel wire, welded into uniform mesh grids (usually 60×80mm or 80×100mm) to prevent aggregate loss. The wire is galvanized or PVC-coated for corrosion resistance, ensuring longevity in moist environments like riverbanks or coastal areas. When filled, the reno mattress conforms to uneven surfaces, distributing weight evenly to stabilize soil and resist erosion from water flow. Common applications include canal linings, lake shore protection, and road embankment reinforcement. Its flexibility allows it to absorb water pressure and minor ground movement, reducing the risk of cracking— a key advantage over rigid concrete solutions.

Gabions and Reno Mattresses: Complementary Tools in Erosion Control

Gabions and reno mattresses are both wire mesh structures filled with aggregates, but their distinct designs make them complementary in erosion control projects. Gabion boxes (taller, rectangular) excel at vertical support (e.g., retaining walls), while reno mattress (flat, shallow) specializes in horizontal coverage (e.g., slope or riverbed protection).

SHENZHOU TIKE METAL leverages this synergy, offering both products to address full-project needs. For example, a river restoration project might use reno mattress to line the riverbed (preventing scouring) and gabion boxes to build adjacent retaining walls (supporting the banks). The welded mesh of both ensures durability, while their permeability allows water flow, maintaining natural hydrology. What unites gabions and reno mattresses is their reliance on local aggregates, reducing transportation costs and environmental impact. The company’s ability to produce both ensures consistency in material quality and performance, making them a one-stop solution for integrated erosion control.

Reno Mattress Company: SHENZHOU TIKE’s Precision in Manufacturing

As a leading reno mattress company, SHENZHOU TIKE METAL CO.,LTD combines advanced technology with skilled craftsmanship to produce high-quality reno mattresses. Their factory, equipped with automated welding machines and quality control systems, ensures uniform mesh strength and consistent dimensions—critical for reliable performance in harsh environments.

The company’s reno mattress production process starts with high-grade low-carbon steel wire, which is galvanized (for corrosion resistance) or PVC-coated (for extreme conditions like saltwater). Welding is done via computer-controlled machines, ensuring each mesh joint is strong and evenly spaced, preventing aggregate leakage. Skilled workers inspect each mattress for defects, from wire thickness to coating adhesion, guaranteeing compliance with industry standards (e.g., ASTM A975). As a reno mattress company, their commitment to innovation includes customizable sizes (lengths up to 6m, widths up to 2m) and mesh configurations, catering to projects from small garden slopes to large-scale dam reinforcements.

Reno Mattress: Custom Solutions for Diverse Project Requirements

Reno mattress is highly customizable, with specifications tailored to project-specific demands—from mesh size to coating type— ensuring optimal performance in varied environments. SHENZHOU TIKE METAL excels in this customization, adapting their reno mattress to meet unique challenges.

For coastal projects, they offer PVC-coated reno mattress to resist saltwater corrosion; for mountain slopes, thicker-gauge wire (3.0mm) provides enhanced tensile strength. Mesh sizes range from 50×50mm (trapping fine aggregates) to 100×100mm (accommodating larger stones), while panel dimensions are adjusted to fit project scales (e.g., 4m×2m for highway slopes, 1m×1m for residential gardens). This flexibility extends to installation: their reno mattress includes interlocking systems, allowing easy on-site assembly without specialized tools. By prioritizing customization, the company ensures their reno mattress meets not just general standards, but the specific needs of each project.

Frequently Asked Questions About Reno Mattress and Related Products

How does reno mattress differ from traditional gabion boxes in installation?

Reno mattress is lighter and flatter, making it easier to transport and install on slopes or uneven terrain. Its interlocking panels connect quickly, requiring fewer workers than gabion boxes (which need vertical alignment). Both use local aggregates, but reno mattress’s shallow depth reduces filling time for horizontal projects.

What roles do gabions and reno mattresses play in environmental projects?

Gabions and reno mattresses support eco-friendly projects by promoting natural water flow (reducing flooding risk) and using local aggregates (lowering carbon footprint). They stabilize soils without disrupting ecosystems, making them ideal for wetland restoration, riverbank protection, and wildlife habitat preservation.

Can a reno mattress company like SHENZHOU TIKE produce mattresses for saltwater environments?

Yes, as a reno mattress company, they offer PVC-coated reno mattresses, which resist saltwater corrosion. These are used in coastal erosion control, marina construction, and saltwater canal lining, maintaining integrity even in high-salinity conditions.

What is involved in reno mattress disposal at the end of its lifespan?

Reno mattress disposal is environmentally friendly: the steel mesh is recyclable (melted and repurposed), and the aggregate fill can be reused in other construction projects. This reduces waste, aligning with sustainable construction practices— a benefit highlighted by SHENZHOU TIKE in their product lifecycle guidance.

|

Product Type

|

Key Specifications

|

Primary Applications

|

Complementary Products

|

|

Reno Mattress

|

50×50mm mesh, 2.5mm wire, galvanized

|

Riverbed lining, slope stabilization

|

Gabion boxes (bank support)

|

|

Gabions and Reno Mattresses (Combined)

|

Gabion: 1m×1m×0.5m; Reno: 4m×2m×0.1m

|

Integrated river restoration projects

|

Local stone aggregates

|

|

Reno Mattress (PVC-coated)

|

100×100mm mesh, 3.0mm wire

|

Coastal erosion control, saltwater canals

|

Gabion baskets (shoreline retaining)

|

|

Reno Mattress (custom)

|

6m×2m length/width, 0.2m depth

|

Large dam reinforcements, highway slopes

|

Welded wire mesh panels (accessories)

|

In summary, reno mattress stands as a versatile solution in erosion control, complemented by gabions to address diverse project needs. As a trusted reno mattress company, SHENZHOU TIKE METAL CO.,LTD combines precision manufacturing with customization, ensuring their products meet the highest standards of durability and performance. Whether used alone or with other gabion structures, their reno mattress exemplifies the blend of strength, sustainability, and adaptability critical to modern civil engineering.