PVC wire netting has emerged as a versatile and essential material in various industries, revered for its durability, flexibility, and adaptability. As an experienced SEO expert, I will delve into the unique properties and applications of PVC wire netting, establishing its importance in modern-day applications with emphasis on Experience, Expertise, Authoritativeness, and Trustworthiness.

PVC wire netting, also known as PVC-coated wire mesh, is composed of metallic wires that have been securely coated with polyvinyl chloride. This process not only enhances the wire's strength and corrosion resistance, making it suitable for both indoor and outdoor use, but also offers an appealing aesthetic look with a variety of color options.

From my extensive experience in industrial material applications, one key benefit of PVC wire netting is its unparalleled durability. Unlike regular wire mesh that can easily succumb to rust and elements, PVC-coated versions resist environmental wear and tear, providing long-lasting functionality. This makes it an ideal choice for fencing in agricultural and residential settings, where exposure to the elements is a primary concern.

Expert opinions corroborate the efficacy of PVC wire netting in enhancing safety and security across various infrastructures. Experts attest to its use in the creation of barriers and enclosures in construction sites, ensuring safe zones for workers while preventing unauthorized access. The customization capability for different mesh sizes and wire thickness further elevates its utility, as it can be tailored to specific security needs.

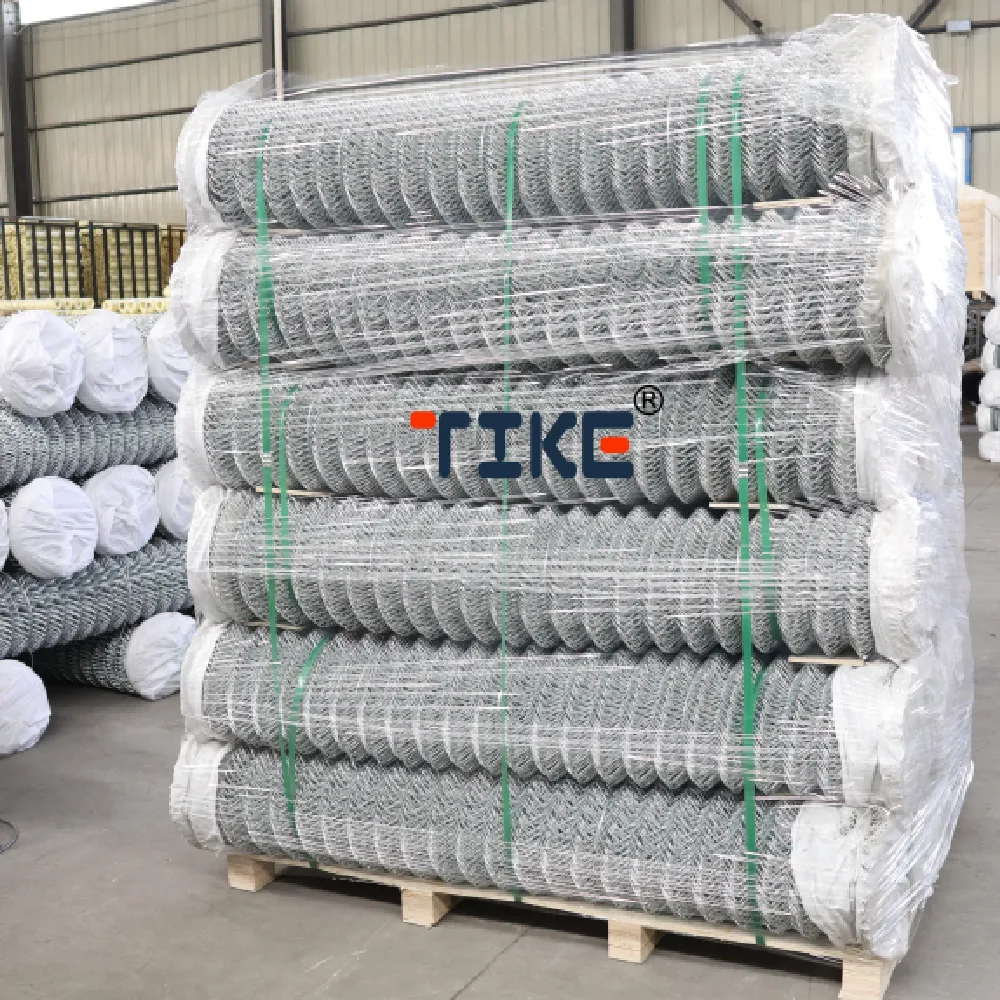

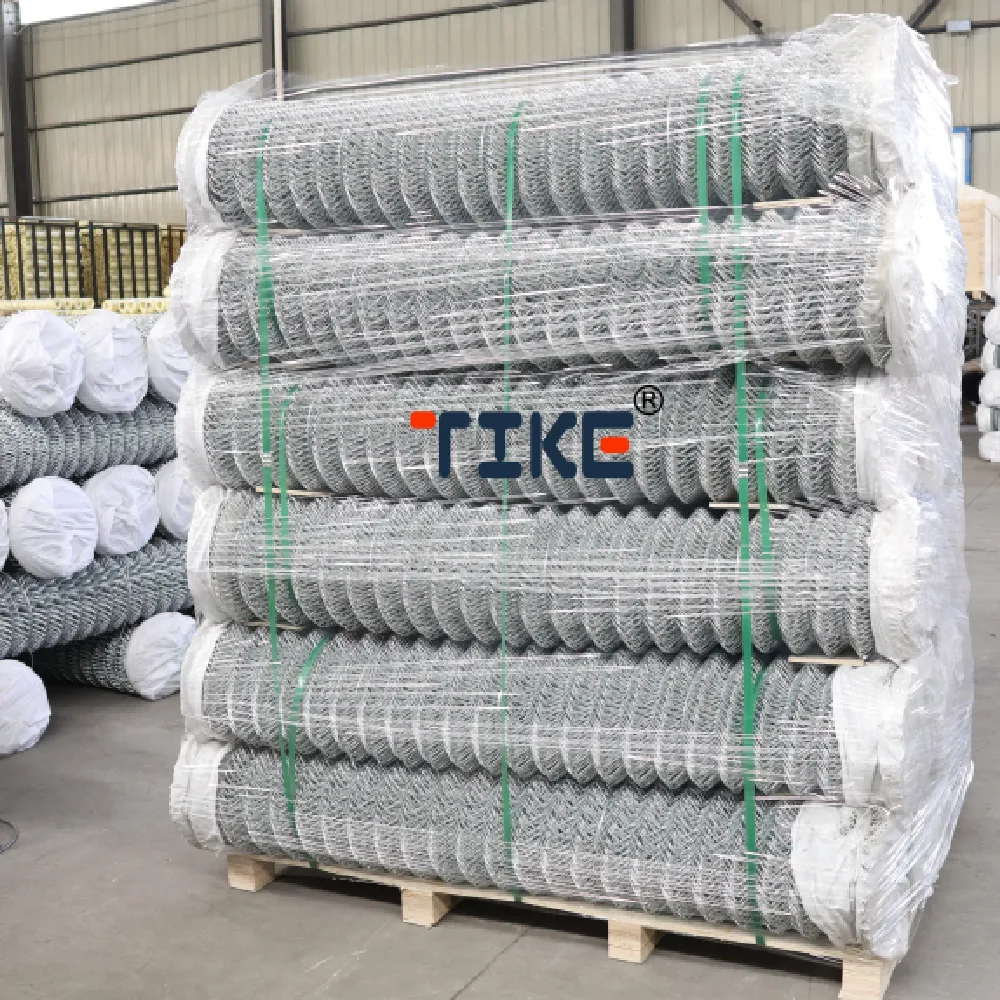

pvc wire netting

From an authoritative standpoint, PVC wire netting is preferred in industries demanding high compliance with rigorous standards of quality and reliability. Noteworthy is its compliance with global safety standards, being non-toxic and environment-friendly, which underscores its authoritative use in both residential and public applications, such as playground fencing, livestock containment, and sports facilities.

Trustworthiness is a core attribute associated with manufacturers of high-quality PVC wire netting. Over the years, brands that adhere to stringent manufacturing protocols have established a reputation for trust, providing products that consistently meet the durability and safety expectations of consumers. Moreover, the transparency of these manufacturers in providing relevant product information, certifications, and usage guidelines fosters an environment of trust with their clientele.

Product-wise, PVC wire netting caters to diversified market needs, ranging from lightweight options for decorative purposes to robust mesh variants engineered for heavy-duty tasks. Cutting-edge advancements in manufacturing processes have introduced enhanced features, such as UV resistance and additional anti-corrosive coatings, which further extend the product's longevity and usage prospects.

In conclusion, the evolution of PVC wire netting from a mere wire enclosure to a multi-faceted solution across various industries is testament to its significance. By embracing its unique characteristics and inherent benefits, expanded applications continue to emerge, cementing its status as a crucial product. Drawing from experience, expertise, authority, and trust, PVC wire netting not only meets contemporary market demands but also paves the way for future innovations, reinforcing its integral position in the toolkit of builders, engineers, and hobbyists alike.