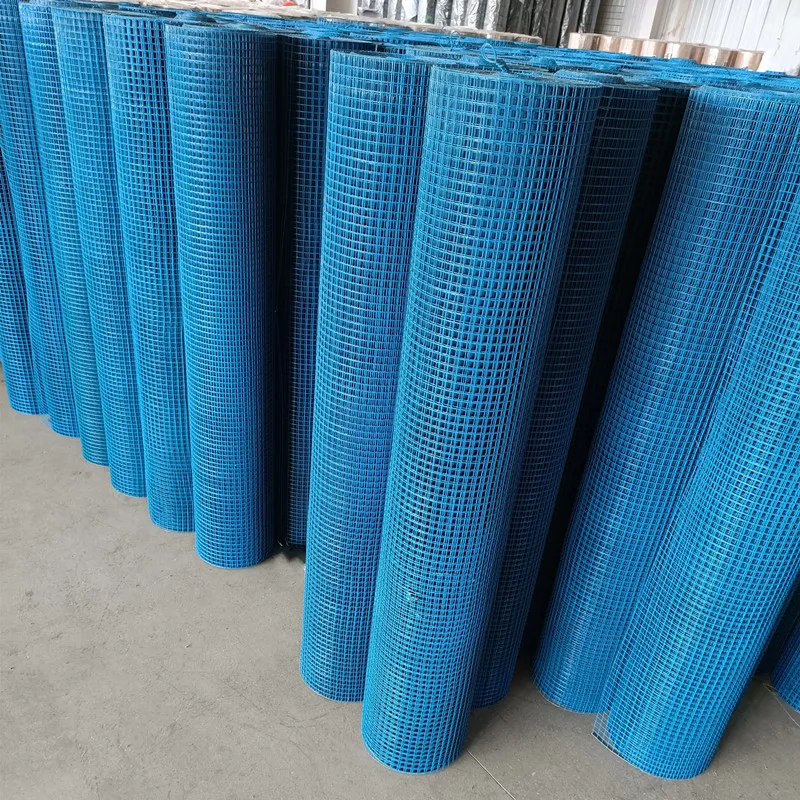

If you manage fences, cages, or safety perimeters, you know coatings aren’t just cosmetic. The right polymer coat can mean the difference between three seasons and a decade of clean service. Lately the market for PVC Coated Welded Wire Mesh has nudged upward—driven by solar farms, logistics parks, urban landscaping, and frankly, better coating tech. Many buyers tell me they want tidy installs, zero rust bleed, and predictable lead times. Not a lot to ask, but supply chains sometimes disagree.

| Base wire | Low-carbon steel (≈Q195/SAE1008), pre-galv or hot-dip galv |

| Mesh opening | 12.7×12.7 mm to 100×100 mm (custom on request) |

| Wire Ø (core + PVC) | Core 1.2–3.5 mm; final Ø ≈1.6–4.2 mm |

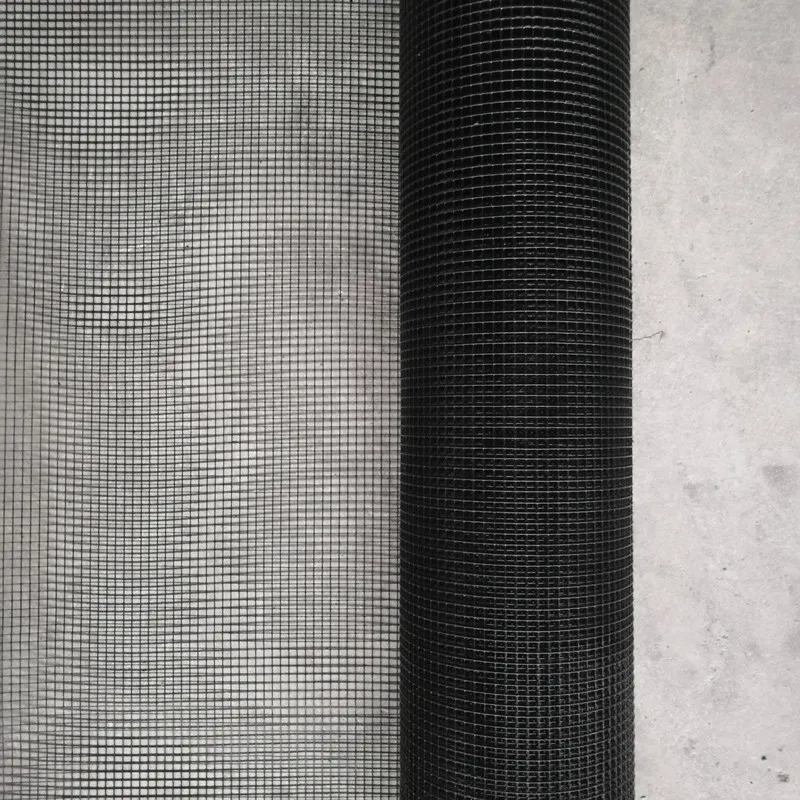

| PVC thickness | ≈0.25–0.6 mm (real-world may vary ±0.05 mm) |

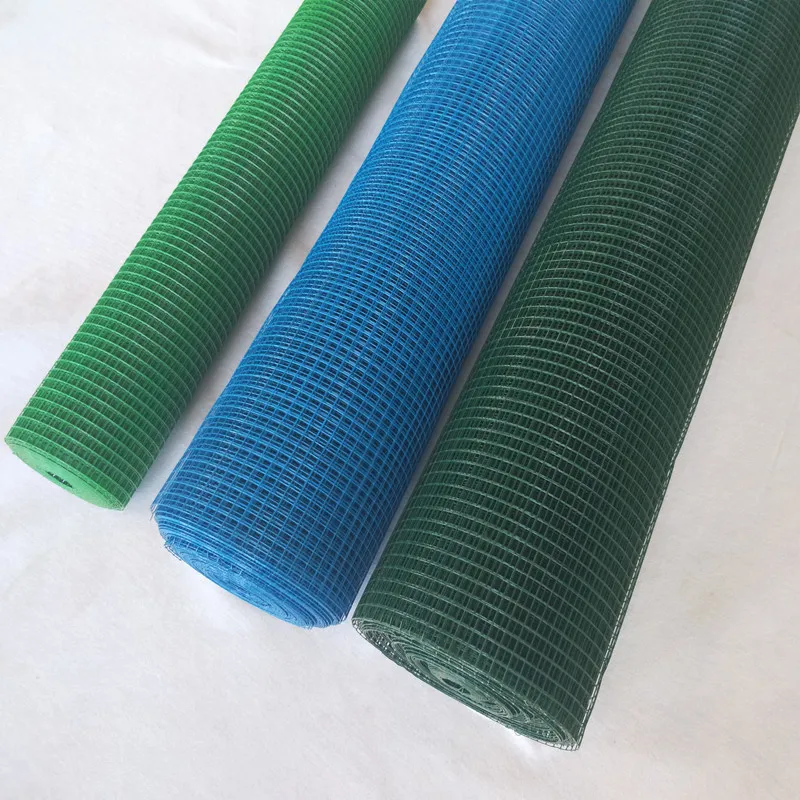

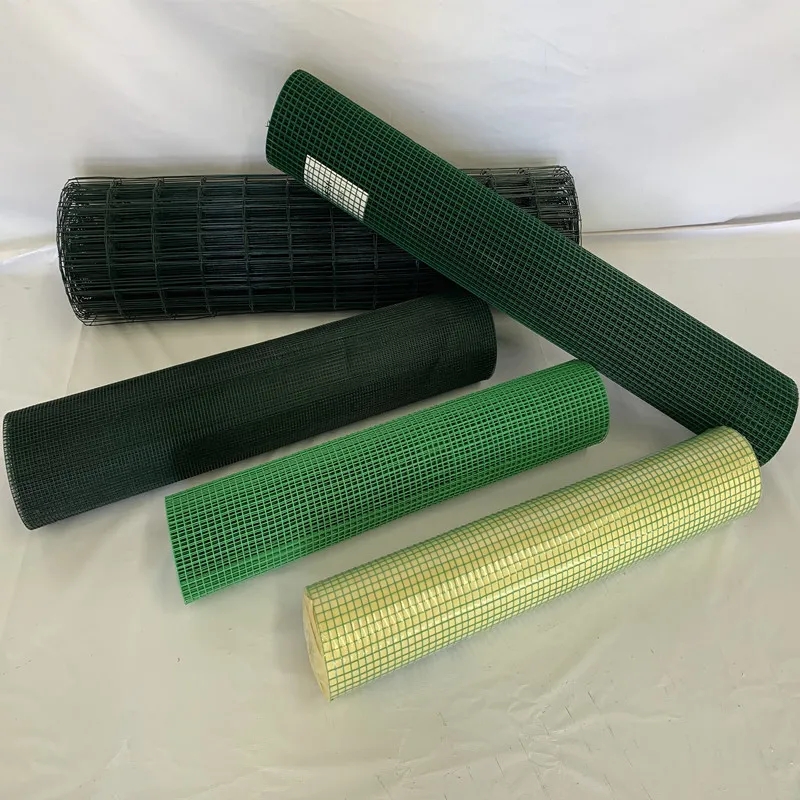

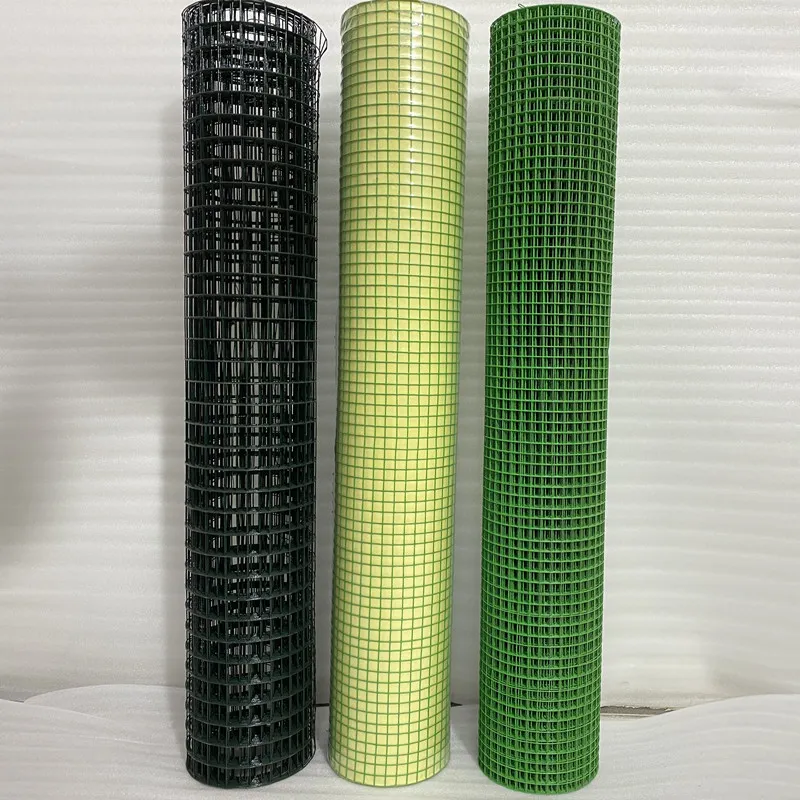

| Colors | Green RAL6005, Black RAL9005, Grey RAL7016, others |

| Salt-spray benchmark | ≥500 h (standard), ≥1,000 h available, ISO 9227 |

| Tensile strength | ≈350–550 MPa (wire grade dependent) |

Perimeter fencing for logistics parks, farm animal enclosures (no sharp burrs), landscaping dividers, HVAC/compressor guards, construction site safety rails, solar/PV perimeters, and light-duty machine guarding. Many customers say the “simple and firm structure, easy installa…”—yes, installation—keeps labor hours in check.

Mesh size, wire gauge, color, roll vs. panel, post kits, and branded labels. REACH/RoHS-compliant PVC is now standard for most export buyers; ISO 9001-backed traceability is frankly expected. I guess the surprise is how consistently PVC Coated Welded Wire Mesh holds color under UV in hot climates—good additive packages help.

| Vendor | PVC thickness | Salt spray | Lead time | Certs |

|---|---|---|---|---|

| Tike Metal (Hebei) | ≈0.4–0.6 mm | ≥1,000 h (option) | 10–20 days | ISO 9001, REACH/RoHS |

| Regional Trader | ≈0.3–0.5 mm | ≈500–720 h | 20–30 days | ISO 9001 |

| Low-cost Supplier | ≈0.25–0.35 mm | ≈240–480 h | ≈30+ days | — |

Logistics park, coastal city: 2.1 m green panels, 60×60 mm mesh, 1,000 h salt spray spec. After 18 months: no blistering, minor scuffs only. Supervisor said installation was “shockingly fast.”

Free-range farm, inland: 50×50 mm rolls, reinforced edges. Animals test everything; welds held, zero wires popped. To be honest, that’s the metric that counts.

Factory origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province.

RELATED PRODUCTS