If you’re weighing durability vs. cost, PVC Coated Welded Wire Mesh quietly fixes problems before they start. To be honest, that’s what many site managers want: fewer headaches, fewer returns. I toured a plant in Hebei last spring and—unsurprisingly—the most popular orders were green panels for logistics yards and marine-adjacent sites where salt mist is a bully.

Two trends are obvious: color-coded site safety (green/black/gray) and longer-life coatings. Buyers want 8–15 years of service life with basic maintenance. Actually, some facilities push for 20 years with thicker PVC and heavy galvanizing. Sustainability is no longer lip service; low-VOC PVC and RoHS/REACH compliance are becoming tender checkboxes.

- Materials: low-carbon steel wire (Q195/Q235), typically zinc-coated per ASTM A641 or hot-dip per ISO 1461 before coating.

- Welding: automatic resistance welding; flatness and weld shear tested to ASTM A185 principles (or GB/T equivalents).

- Pretreat: degrease → rinse → phosphating (optional) → drying.

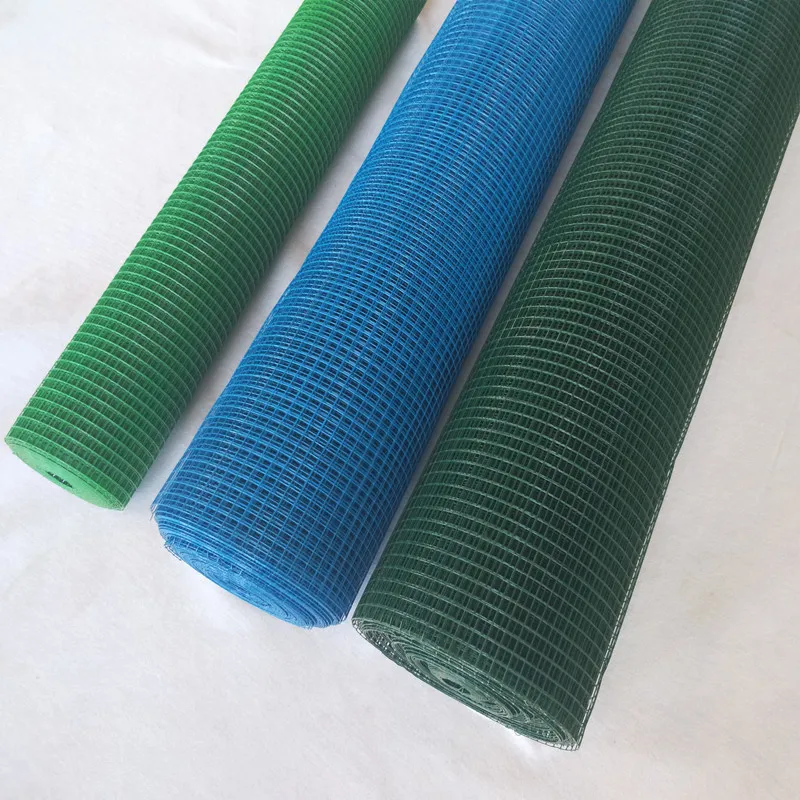

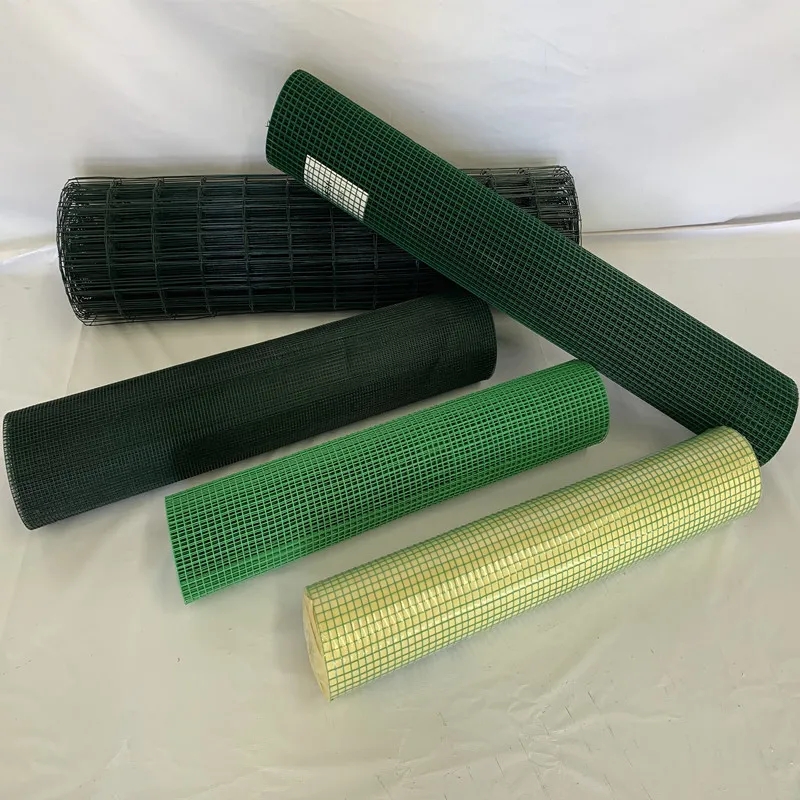

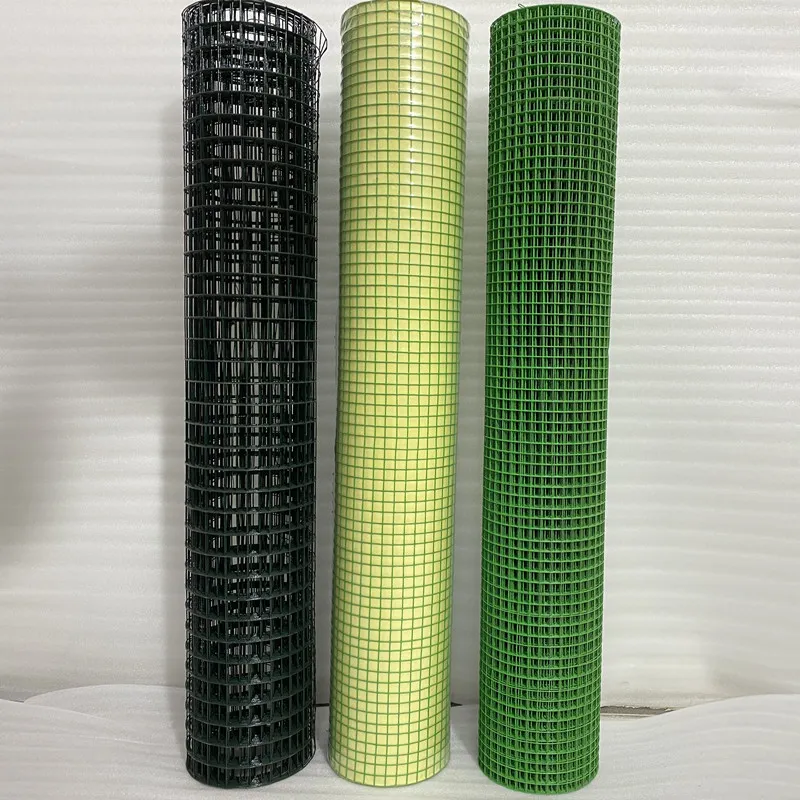

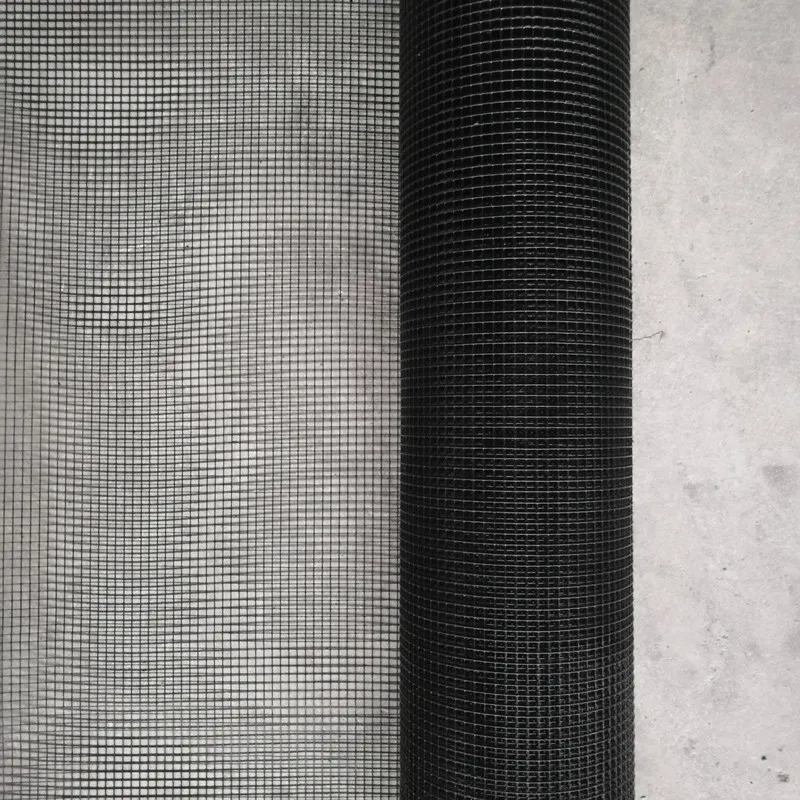

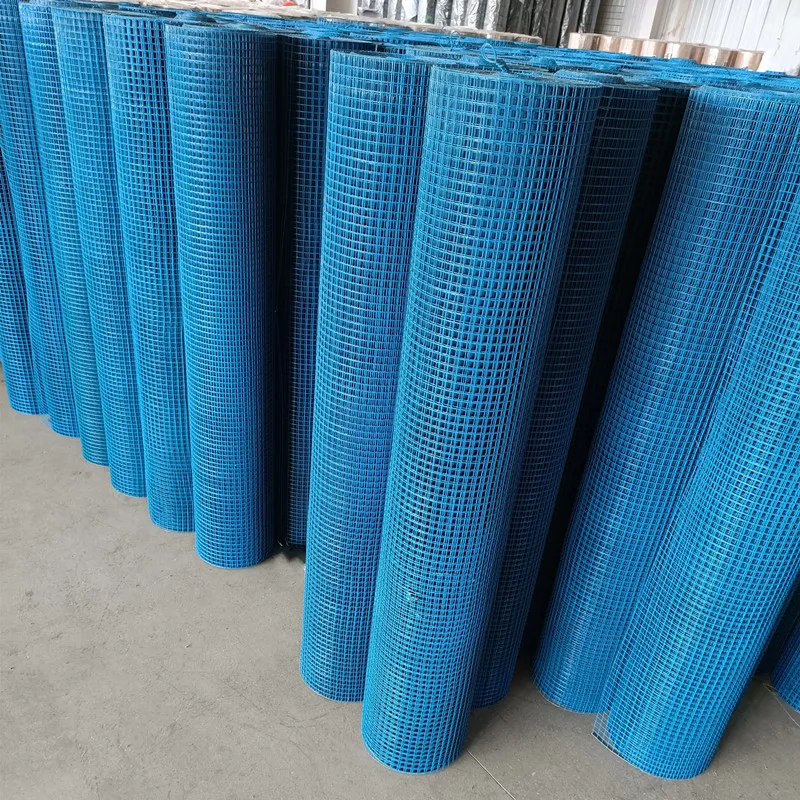

- PVC coating: fluidized-bed or extrusion. Typical PVC thickness ≈ 0.4–1.0 mm, colors: green RAL6005, black, gray; custom on request.

- Tests: adhesion (cross-hatch), impact, bend (180°), salt spray per ISO 9227 or ASTM B117.

Lab snapshots (typical, may vary): neutral salt spray 720–1,000 h with no base metal rust; UV aging 500 h with ΔE ≤ 2.0 on quality batches. In the field, I’d budget 10–15 years in temperate climates, around 5–10 in coastal Category C5 unless you spec thicker PVC and heavy zinc.

| Item | Spec (≈) |

|---|---|

| Mesh opening | 12.7×12.7 mm to 100×100 mm |

| Core wire dia. | 1.8–4.0 mm |

| After-coating dia. | 2.4–5.0 mm |

| PVC thickness | 0.4–1.0 mm |

| Panel/Roll size | Panels up to 2.4×3.0 m; rolls 0.9–1.8 m × 25–30 m |

| Colors | Green, black, gray; RAL custom |

Perimeter fencing, construction hoarding, HVAC/equipment cages, animal enclosures, warehouse partitioning, sports grounds, solar farm security, roadside safety (as anti-throw barriers), and even light architectural screens. Many customers say the tidy look lasts longer than painted mesh—less chalking, less flake.

| Vendor | Coating | Lead time | Certs | Notes |

|---|---|---|---|---|

| Tikemetal (Hebei) | PVC 0.6–1.0 mm, galvanized core | 10–20 days | ISO 9001, RoHS/REACH | Factory-direct, custom RAL |

| Vendor B | PVC ≈0.5 mm | 20–30 days | ISO 9001 | Limited mesh sizes |

| Vendor C | PVC ≈0.4–0.6 mm | 15–25 days | CE (applicable) | Budget option |

- Coastal solar farm: spec’d PVC Coated Welded Wire Mesh 50×100 mm, 3.0/4.0 mm after-coat; achieved ≈1,000 h NSS test. After 18 months, no underfilm rust observed.

- Food plant partition: black PVC Coated Welded Wire Mesh to hide scuffs; facility team praised easier wash-down, zero repaint in year one.

- Public park: child-safe edges (wire ends trimmed/rolled), green RAL6005; vandal scratches didn’t creep rust thanks to thick PVC.

Mesh opening, panel/roll size, wire gauge, PVC thickness, RAL color, post systems, and branded tags are all doable. QC includes weld shear, coating adhesion (cross-hatch), thickness gauges, and batch salt spray. Real-world use may vary—always align spec with environment class (C2–C5).

Customer voice: “Looks professional even after a muddy winter,” a UK site foreman told me. That tracks with my own notes.

Origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province.

RELATED PRODUCTS