Iron wire, an essential component in various industries, plays a crucial role in construction, manufacturing, and domestic applications. Understanding the price dynamics of iron wire is vital for businesses and buyers aiming to optimize their procurement strategies. Here, we explore the factors that influence its pricing, the current market trends, and insights from industry experts that underscore the expertise, authority, and trustworthiness of this analysis.

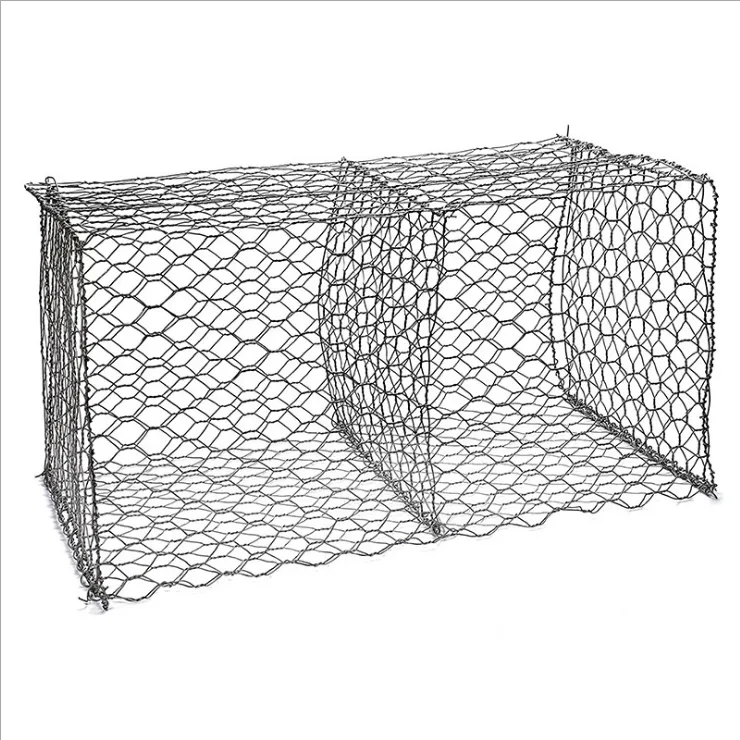

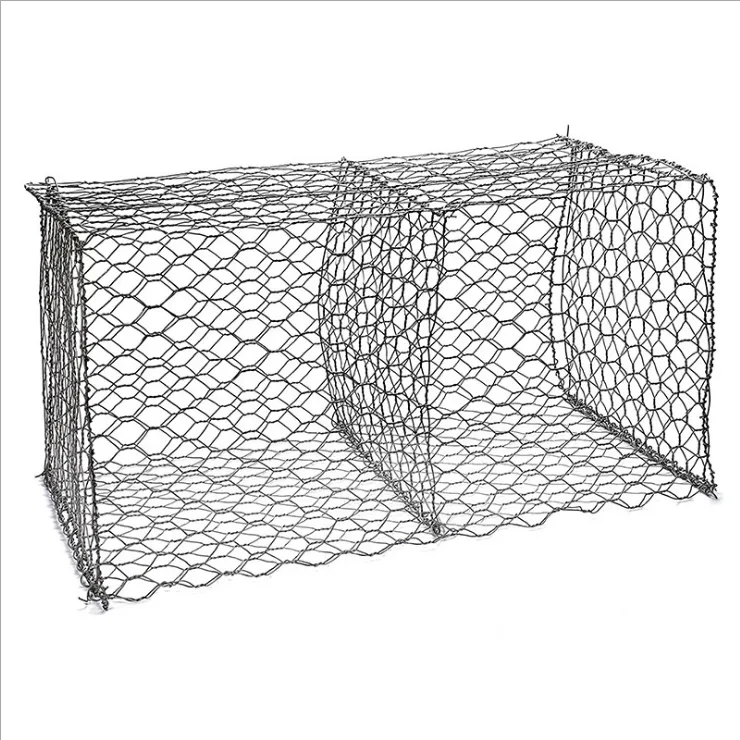

Iron wire serves many purposes, from being a fundamental element in the creation of fences and mesh to serving its role in binding and tying applications. As such, the price of iron wire is affected by multiple variables including raw material cost, manufacturing processes, global demand, and geopolitical factors.

Iron, the primary material in iron wire, is sourced mainly from iron ore.

The fluctuation in iron ore prices directly impacts the cost of iron wire. This fluctuation can stem from mining conditions, availability of the ore, or economic policies in leading production countries like China, Australia, and Brazil. In recent years, for instance, changes in China’s industrial policies and environmental regulations have caused notable fluctuations in iron ore prices, thereby influencing iron wire costs.

Manufacturing processes also play a significant role in determining the price. Advances in technology can streamline production, reduce waste, and improve quality, which can either reduce costs or add value to the final product, depending on how these improvements are leveraged. For example, the adoption of automated precision equipment in wire drawing can lead to reduced labor costs and enhanced efficiency, potentially lowering the price of iron wire or justifying a premium for higher-grade products.

Global demand for iron wire is influenced by sectors such as construction, automotive, and even the electronics industry. The construction sector, which requires vast amounts of iron wire for reinforcing structures and creating frameworks, is a substantial contributor to demand. Economic booms in developing nations often lead to increased infrastructure projects, escalating demand for construction materials including iron wire. Conversely, a slowdown in these economies can lead to reduced demand, impacting prices globally.

In terms of geopolitical factors, trade policies and international relations can significantly alter supply chains and cost structures. Tariffs or trade embargoes on raw materials or finished goods can affect production costs and availability, thus impacting pricing. For instance, recent trade tensions between major economies have led to unpredictable fluctuations in metal prices, including iron wire, thereby affecting international supply chains and pricing strategies.

price of iron wire

Market trends indicate a growing emphasis on sustainability and eco-friendly products. Manufacturers that employ sustainable practices and create iron wire from recycled materials may face different pricing strategies. While production costs might be higher initially, the end products may command premium prices due to their environmental benefits, aligning with the increasing consumer emphasis on sustainability.

Expert industry analysis highlights the importance of monitoring market indices and purchasing futures to hedge against volatile price changes. Leading financial experts typically recommend diversifying sourcing to include multiple suppliers, thus reducing dependency on a single provider and mitigating risks associated with supply chain disruptions.

For businesses, understanding and forecasting iron wire prices require a mix of experience, professional insight, and authoritative data analysis. Access to up-to-date market reports and historical pricing data can provide a competitive edge. It’s also crucial to maintain strong relationships with suppliers to ensure reliable pricing information and negotiate better terms.

Trustworthy interaction within the industry can be fostered by engaging with well-established partners and utilizing reputable market analysis tools. Businesses that are transparent about their supply chain practices and responsive to changes are often more resilient in adapting to price fluctuations.

In summary, the price of iron wire is a multifaceted topic influenced by raw material costs, manufacturing processes, market demand, and geopolitical factors. Those involved in purchasing iron wire should prioritize informed decision-making backed by expert advice and authoritative data analysis to navigate this complex landscape effectively. By integrating experience and professional insights, businesses can optimize their procurement strategies and maintain competitiveness within their respective markets.