The global industrial landscape consistently demands materials that offer unparalleled strength, durability, and corrosion resistance. In this evolving environment, Stainless Steel Welded Wire Mesh stands out as a critical component, enabling advancements across diverse sectors. Its unique combination of material properties and precise fabrication makes it indispensable for applications requiring high structural integrity and longevity. From sophisticated filtration systems to robust security barriers, the demand for high-performance wire mesh solutions continues to escalate, driven by stringent industry standards and the need for reliable, long-lasting infrastructure. This article delves into the intricate details of this essential material, exploring its manufacturing excellence, technical specifications, and expansive applications that are shaping modern industrial practices.

Recent market analyses indicate a steady growth trajectory for the stainless steel products market, with a particular emphasis on fabricated forms like wire mesh. This trend is fueled by increasing investments in infrastructure, the booming renewable energy sector, and the continuous modernization of manufacturing processes worldwide. Enterprises are increasingly prioritizing materials that promise reduced maintenance costs, extended service life, and adherence to rigorous environmental and safety regulations. As such, understanding the technical nuances and application versatility of Stainless Steel Welded Wire Mesh is crucial for B2B decision-makers seeking optimal material solutions for their projects. Its inherent resistance to rust, staining, and impact, combined with its aesthetic appeal, positions it as a preferred choice over conventional materials in demanding environments.

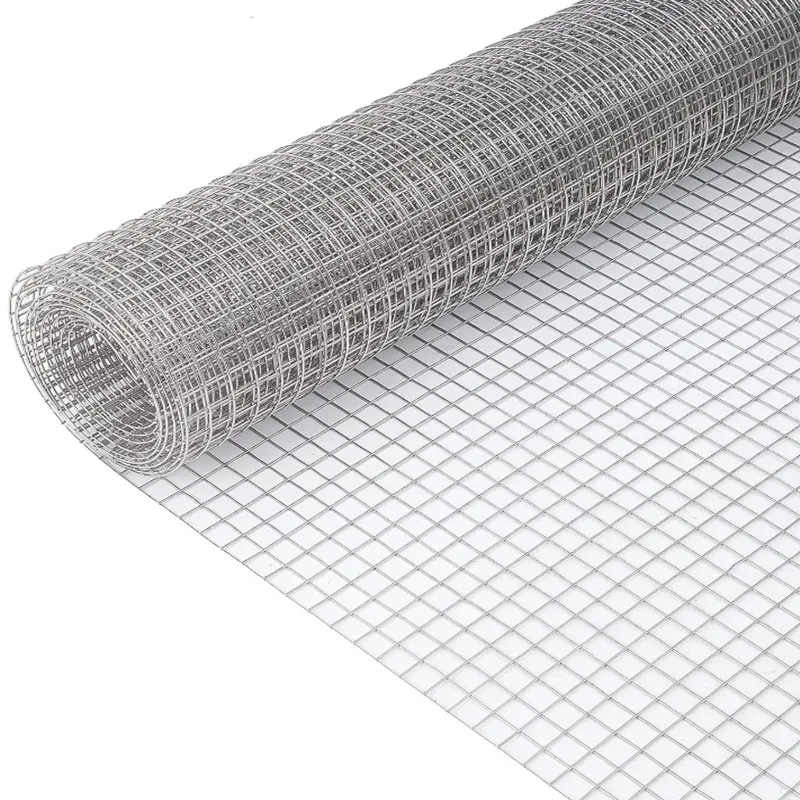

The production of Stainless Steel Welded Wire Mesh is a meticulous multi-stage process that ensures its exceptional quality and performance. It begins with the selection of premium stainless steel wire, typically grades like AISI 304, 316, 304L, or 316L, chosen for their specific corrosion resistance and mechanical properties. The manufacturing process fundamentally involves drawing the raw steel into precise wire diameters and then employing automated resistance welding techniques. During welding, individual longitudinal and transverse wires are fused at their intersections, creating a strong, rigid, and uniform mesh structure. This method ensures consistent aperture size and maximum joint integrity, which is vital for filtration, screening, and structural applications.

Following the welding phase, the mesh undergoes several finishing treatments to enhance its durability and appearance. Common post-weld treatments include pickling and passivation, which remove impurities and reinforce the passive chromium oxide layer on the surface, significantly boosting corrosion resistance. For applications requiring an exceptionally smooth, sterile, or highly polished finish, electropolishing may be employed. Quality control is paramount at every stage, with stringent inspections against international standards such as ISO 9001 and ASTM A740. These checks cover wire diameter accuracy, mesh aperture consistency, weld strength, and surface finish. The rigorous adherence to these standards ensures a reliable product with an extended service life, often exceeding 20-30 years in non-aggressive environments, making Stainless Steel Welded Wire Mesh ideal for sectors like petrochemical, water treatment, mining, and food processing, where material integrity is non-negotiable.

Figure 1: Precision welding of Stainless Steel Welded Wire Mesh.

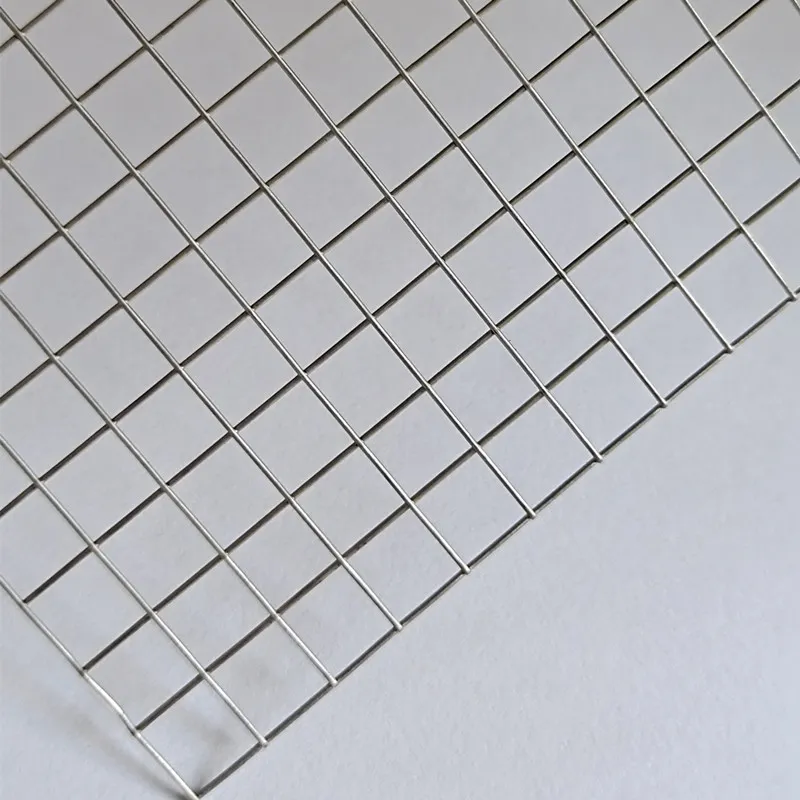

Understanding the technical specifications of Stainless Steel Welded Wire Mesh is crucial for proper material selection. Key parameters include wire diameter, mesh aperture (opening size), mesh count (number of openings per linear inch), and material grade. Wire diameters typically range from 0.4 mm to 6.0 mm, affecting both strength and flexibility. Mesh apertures can vary from very fine (e.g., 200 mesh for ultra-fine filtration) to very coarse (e.g., 50x50 mm for security fencing), directly influencing filtration efficiency or structural support. Common material grades include SS304 for general-purpose corrosion resistance and SS316 for enhanced resistance in aggressive chloride environments, such as marine or chemical processing applications. The tensile strength of the wire, a measure of its resistance to breaking under tension, is also a critical specification, often ranging from 520 MPa to 720 MPa depending on the alloy and wire drawing process.

Figure 2: Close-up view of precise Stainless Steel Welded Wire Mesh.

To aid in material selection, the following table outlines typical specifications for widely used Stainless Steel Welded Wire Mesh products. These values are indicative and can be customized based on specific project requirements, highlighting the flexibility offered by manufacturers. Understanding these parameters ensures optimal performance and cost-effectiveness for applications ranging from industrial baskets to architectural facades.

The robust properties of Stainless Steel Welded Wire Mesh make it an incredibly versatile material, finding application across a multitude of industries. In construction, it serves as a critical reinforcement for concrete, enhancing structural integrity and crack resistance in flooring and walls. Its non-corrosive nature is particularly beneficial in coastal regions or areas with high humidity. For the food and beverage industry, its hygienic properties and ease of cleaning make it ideal for conveyor belts, drying racks, and protective screens, meeting strict FDA compliance for food contact materials when specific grades are used. In the petrochemical sector, it is extensively used for catalyst support grids, strainers, and security fencing around hazardous areas, leveraging its resistance to high temperatures and aggressive chemicals.

Beyond these sectors, Stainless Steel Welded Wire Mesh is integral to mining (screening and separation), agriculture (animal enclosures, crop protection), automotive (grilles, filters), and architecture (decorative panels, safety barriers). Its technical advantages are numerous:

A notable case involves its use in large-scale water treatment plants, where Stainless Steel Welded Wire Mesh acts as filtration media, preventing debris from entering critical pump systems. Its resistance to biofouling and chemical exposure ensures consistent water flow and significantly reduces downtime for cleaning and repairs, contributing to substantial operational savings.

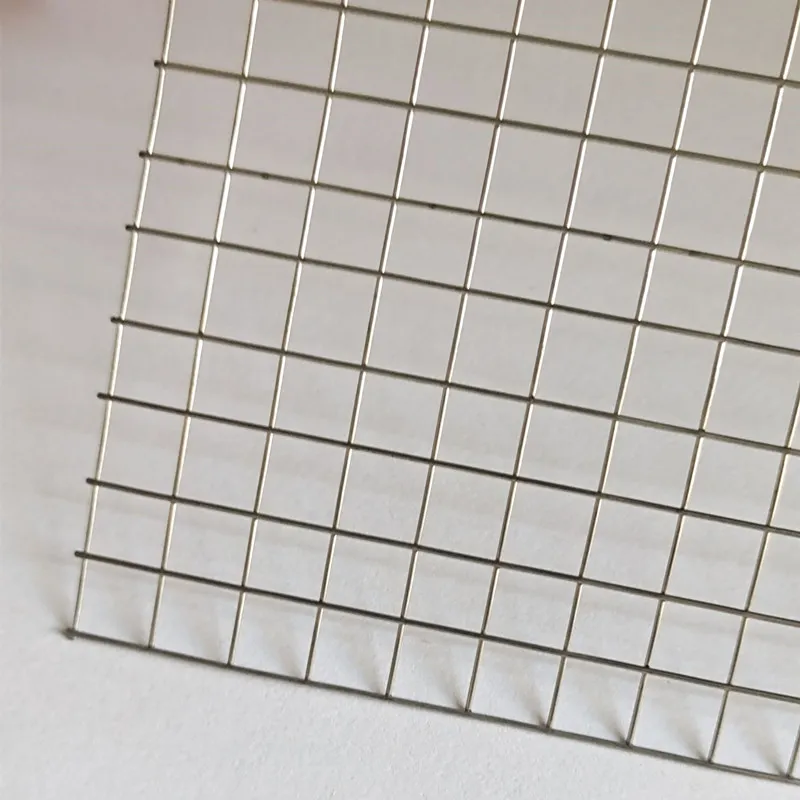

Figure 3: Stainless Steel Welded Wire Mesh in a typical industrial application.

Selecting a reliable manufacturer for Stainless Steel Welded Wire Mesh is as crucial as understanding the product itself. Reputable suppliers distinguish themselves through adherence to international quality standards (e.g., ISO 9001:2015 certified processes), extensive experience in diverse applications, and a robust capacity for customization. When evaluating potential partners, consider their range of material grades, wire diameters, and mesh sizes available. A manufacturer's ability to provide test certificates (e.g., material composition, tensile strength, salt spray test reports) further underscores their commitment to quality and transparency. Furthermore, look for suppliers who offer value-added services such as precise cutting, forming, and even surface treatments like passivation or electropolishing, which can significantly enhance the mesh's performance in specific environments.

Customization is often a key requirement for B2B clients, as standard mesh sizes may not perfectly align with unique project specifications. A skilled manufacturer should be capable of producing Stainless Steel Welded Wire Mesh in bespoke dimensions, panel sizes, and even specialized configurations to meet precise needs. This includes variations in mesh opening shapes, wire orientations, and post-fabrication services. For instance, a client requiring specific filtration efficiency might need a custom mesh count, while an architectural project could demand unique panel dimensions and surface finishes. Partnering with a manufacturer offering comprehensive design and engineering support can streamline project timelines and ensure the final product seamlessly integrates into the intended application, maximizing efficiency and minimizing unforeseen challenges. Our company has served the industry for over 15 years, providing customized solutions to global clients, consistently meeting stringent quality benchmarks and unique operational demands.

Ensuring the highest quality of Stainless Steel Welded Wire Mesh involves stringent adherence to internationally recognized standards and a robust quality assurance framework. Our products consistently meet or exceed benchmarks set by ISO 9001 for quality management systems and ASTM standards for material specifications. Each batch undergoes rigorous testing, including material chemical analysis, tensile strength tests, and visual inspections for weld integrity and surface finish. For specific applications, we can provide certifications conforming to industry-specific requirements, such as those for food-grade materials or high-temperature environments. Our commitment extends to providing comprehensive documentation, including Mill Test Certificates (MTCs), ensuring full traceability of materials from raw input to finished product, building trust and transparency with our clients.

A: SS304 is the most common grade, offering good corrosion resistance for general applications. SS316 contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride-rich environments like marine or chemical processing.

A: Resistance welding creates strong, permanent bonds at each intersection, ensuring uniform strength across the entire sheet. This precise method prevents unraveling and provides superior dimensional stability compared to woven meshes, contributing significantly to the mesh's overall durability and longevity.

A: Lead times vary depending on complexity, quantity, and current production schedules. Standard orders typically ship within 2-4 weeks. Custom or large-volume orders may require 4-8 weeks, with specific timelines provided upon detailed order confirmation. We prioritize efficient production and logistics to meet client deadlines.

A: We offer a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Our dedicated customer support team is available for technical inquiries, product guidance, and addressing any post-delivery concerns, ensuring complete client satisfaction and long-term partnership.

Our dedication to client support extends beyond delivery. We understand that selecting and implementing industrial materials involves complex considerations. Our technical experts are available to assist with material selection, custom design requirements, and application-specific advice, ensuring that every client receives the optimal Stainless Steel Welded Wire Mesh solution tailored to their precise needs. This holistic approach to product quality and customer service underpins our commitment to being a trusted partner in your supply chain.

In conclusion, Stainless Steel Welded Wire Mesh represents a cornerstone material in modern industrial applications, embodying the perfect blend of strength, corrosion resistance, and versatility. Its meticulous manufacturing process, adherence to rigorous technical specifications, and broad applicability across demanding sectors underscore its critical role in enhancing operational efficiency and safety. As industries continue to evolve and seek more sustainable and durable material solutions, the demand for this high-performance mesh is set to expand further. Partnering with experienced and quality-focused manufacturers capable of delivering both standard and customized solutions is key to harnessing the full potential of this exceptional product.

By integrating advanced materials like Stainless Steel Welded Wire Mesh, businesses can significantly reduce their total cost of ownership through minimized maintenance and prolonged asset lifespans. This not only translates into direct financial savings but also contributes to greater operational reliability and environmental responsibility. As a core component for a resilient future, its importance cannot be overstated in a world increasingly reliant on robust and adaptable infrastructure.

RELATED PRODUCTS