In industrial applications demanding precise filtration, separation, and screening, the role of high-quality Square Opening Wire Mesh is paramount. Engineered for accuracy and durability, this product category is a cornerstone in various sectors, from petrochemical to food processing. Its uniform apertures ensure consistent performance, critical for maintaining product quality and operational efficiency across diverse manufacturing and processing environments. Our commitment lies in delivering solutions that not only meet but exceed stringent industry specifications, providing exceptional longevity and reliability.

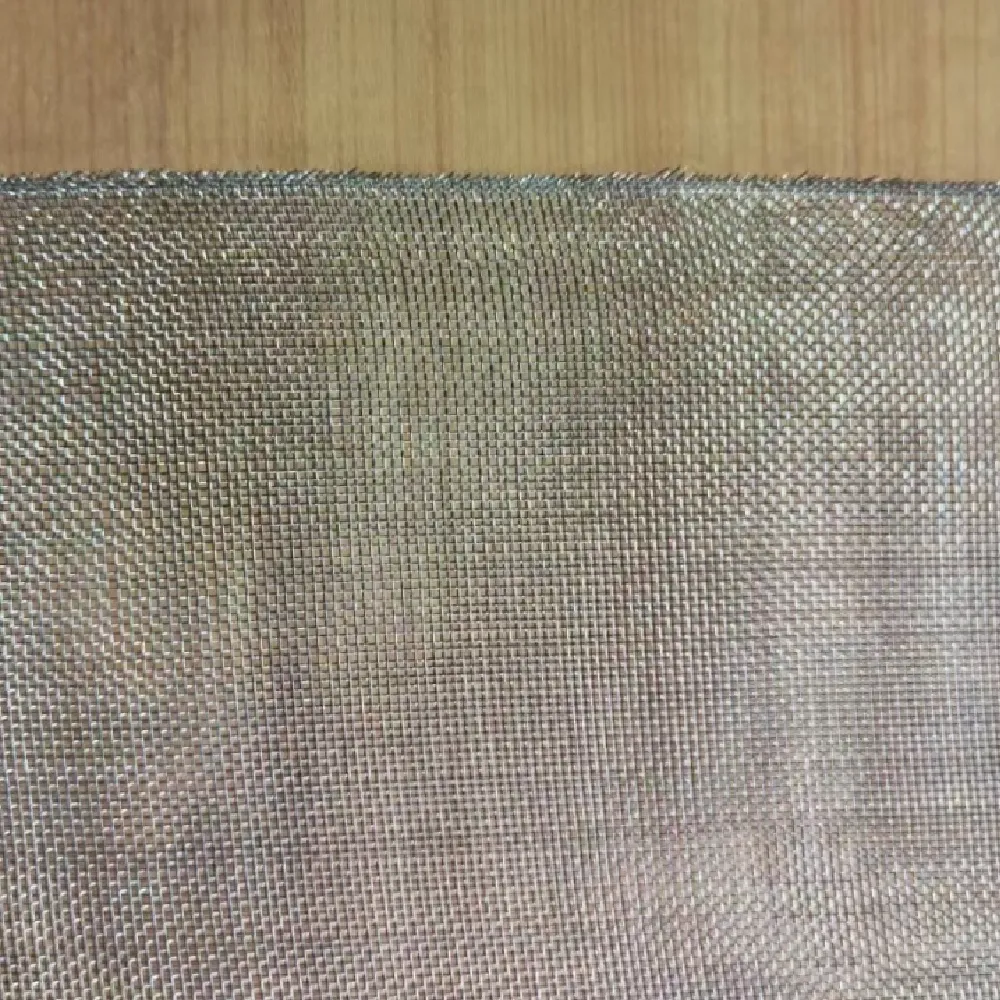

The design of Square Opening Wire Mesh is characterized by evenly spaced wires forming precise square openings, which are crucial for accurate particle sizing and material classification. This foundational characteristic allows for predictable material flow and optimal separation, making it indispensable in modern industrial operations. We delve into the sophisticated manufacturing processes, rigorous quality control, and multifaceted applications that underscore its value.

The market for industrial wire mesh is continually evolving, driven by several key industry trends. Automation and digitalization in manufacturing processes are leading to demands for higher precision and consistency in wire mesh products. There's a growing emphasis on high-performance materials, such as advanced stainless steel alloys (e.g., Duplex and Super Duplex stainless steels) and specialized non-ferrous metals, to withstand increasingly harsh operating environments involving extreme temperatures, corrosive chemicals, and high pressures. This push for superior material science directly impacts the service life and reliability of mesh components.

Sustainability is another significant driver. Manufacturers are increasingly seeking wire mesh solutions that contribute to energy efficiency in separation processes, reduce waste, and are recyclable at the end of their lifecycle. This includes optimizing mesh designs for lower pressure drop in filtration systems, thereby reducing energy consumption. Furthermore, the burgeoning demand in emerging markets, coupled with infrastructure development and stricter environmental regulations, fuels innovation in filtration and screening technologies, placing Square Opening Wire Mesh at the forefront of these advancements. The integration of IoT for real-time monitoring of mesh performance and predictive maintenance also represents a frontier in product development.

The production of high-quality industrial mesh is a meticulous process, beginning with the selection of premium raw materials and culminating in rigorous quality assurance. Our manufacturing protocol is designed to ensure superior product integrity and performance.

We utilize a range of high-grade materials chosen for their specific properties, including:

Raw wire coils undergo precision straightening and cleaning to ensure uniformity and optimal weaving performance.

The core manufacturing technique for Square Opening Wire Mesh is precision weaving. Utilizing advanced automatic looms, warp and weft wires are interlaced under tightly controlled tension to create consistently sized square apertures. The most common weaving patterns include:

Advanced weaving machinery, often featuring CNC controls, ensures minimal deviation in wire spacing and tension, which is critical for achieving the specified mesh count and opening size.

After weaving, the mesh rolls are subjected to various finishing processes:

Our dedication to quality is upheld by stringent testing protocols that adhere to international standards, ensuring that every batch of wire mesh meets the highest performance criteria. Key standards include:

Testing includes visual inspection, measurement of mesh count and wire diameter using optical comparators, tensile strength testing, and corrosion resistance tests (e.g., salt spray tests) where applicable. This ensures long service life, often exceeding 5-10 years under typical operating conditions, depending on material and application severity.

Input Wire Coils ↓ Straightening & Cleaning ↓ Precision Loom Weaving (Warp & Weft Interlacing) ↓ Annealing (Optional) ↓ Slitting & Cutting ↓ Edge Treatment ↓ Quality Control & Testing ↓ Packaging & Shipment

Understanding the precise technical specifications of industrial wire mesh is crucial for optimal application performance. Key parameters include mesh count, wire diameter, opening size (aperture), and open area percentage.

| Mesh Count (per inch) | Wire Diameter (mm) | Opening Size (mm) | Open Area (%) | Material Grade (Common) |

|---|---|---|---|---|

| 4 | 1.60 | 4.75 | 56.7 | 304 SS |

| 10 | 0.80 | 1.74 | 48.3 | 316 SS |

| 20 | 0.40 | 0.87 | 48.3 | 316L SS |

| 50 | 0.25 | 0.26 | 27.0 | 304 SS |

| 100 | 0.10 | 0.15 | 36.0 | 316 SS |

Note: Values are illustrative and can vary based on specific manufacturing tolerances and material properties. Custom specifications are available.

The versatility and precision of Square Opening Wire Mesh make it indispensable across a multitude of industries, serving critical functions in separation, filtration, protection, and support. Its robust design and material adaptability allow for optimal performance in demanding environments.

Our industrial wire mesh offers a distinct set of technical advantages, meticulously engineered to provide superior performance and long-term value in the most demanding industrial settings. These advantages stem from advanced manufacturing techniques and rigorous material selection.

| Feature | Standard Woven Mesh | Advanced Industrial Square Mesh |

|---|---|---|

| Opening Tolerance (Average) | ±8-10% | ±3-5% |

| Service Life (Typical) | 2-5 years | 5-10+ years |

| Corrosion Resistance (SS) | Good | Excellent (with advanced alloys) |

| Pressure Drop in Filtration | Moderate | Low (Optimized open area) |

| Maintenance Frequency | Higher | Lower |

Note: This table provides general comparative insights. Actual performance depends on specific mesh configuration, material, and operating conditions.

Selecting the right vendor for industrial wire mesh is a critical decision that impacts operational efficiency, product quality, and long-term cost of ownership. Beyond initial price, purchasers should evaluate a comprehensive range of factors to ensure optimal partnership.

While price is always a consideration, prioritizing total cost of ownership – including durability, maintenance, and operational efficiency – will lead to more sustainable and profitable outcomes.

Recognizing that standard products cannot always address unique operational challenges, we specialize in providing tailored Square Opening Wire Mesh solutions. Our engineering team collaborates closely with clients to develop custom mesh specifications that precisely meet the demands of their specialized applications.

Our design and manufacturing flexibility ensures that even the most niche requirements for industrial mesh can be met with engineered solutions, providing a competitive edge and optimized performance for our clients.

Our commitment to delivering high-performance woven wire mesh is best demonstrated through its successful deployment in real-world industrial applications. These case studies highlight our capability to provide reliable and efficient solutions that address complex challenges and yield tangible benefits for our clients.

A major petrochemical refinery faced persistent issues with premature clogging and high maintenance costs in their crude oil filtration units. The existing mesh screens offered insufficient durability against abrasive particles and corrosive fluid streams, leading to frequent replacements and operational downtime. Our solution involved designing custom square opening wire mesh made from Duplex Stainless Steel (2205), specified with a unique wire diameter and aperture size to optimize open area while maintaining mechanical strength. The new mesh demonstrated superior corrosion and abrasion resistance, extending the filter element's service life by over 150% and reducing maintenance intervals by 60%. This resulted in significant cost savings and improved process uptime, with the client reporting a positive ROI within 18 months.

A leading food ingredients manufacturer required an ultra-hygienic and precise screening solution for fine powder separation. Their previous mesh exhibited issues with particle agglomeration and difficulty in cleaning, impacting product consistency and compliance with FDA regulations. We provided a customized 316L Stainless Steel square opening mesh, electro-polished for a smoother surface finish to prevent particle adherence and ensure effortless cleaning. The mesh was engineered with a very tight tolerance on aperture size (±3%) to meet specific particle distribution requirements. The client observed a marked improvement in product purity, reduced cleaning times by 40%, and achieved full compliance with stricter hygiene standards, enhancing their brand reputation and operational efficiency.

A large-scale mining operation needed highly durable screening media for aggregate classification that could withstand heavy impact and extreme abrasive conditions. Traditional carbon steel mesh screens failed rapidly, incurring substantial replacement costs and disrupting production schedules. We supplied heavy-gauge, high-tensile carbon steel square opening mesh, featuring a unique crimped weave for enhanced structural rigidity and wear resistance. This specialized mesh significantly outlasted the previous solutions, offering a 300% increase in service life under severe operational stress. The client reported a substantial reduction in screen replacement frequency, leading to increased throughput and lower operational expenditures.

Building long-term partnerships is at the core of our business philosophy. We ensure complete transparency and reliability throughout the client journey, from initial inquiry to post-installation support for your industrial mesh solutions.

Q1: How do I determine the correct mesh count and wire diameter for my application?

A1: Selecting the optimal mesh requires considering particle size distribution, desired flow rate, material characteristics (abrasiveness, corrosiveness), and structural integrity needs. Our technical experts can assist you in calculating the ideal specifications based on your specific operational parameters. Providing details about your process and current challenges will enable us to recommend the most effective square opening mesh configuration.

Q2: What is the typical lead time for custom wire mesh orders?

A2: Lead times for custom orders typically range from 2 to 4 weeks, depending on material availability, complexity of design, and current production schedules. Standard stock items can often be dispatched within 3-5 business days. We provide accurate lead time estimates upon quotation and keep clients informed throughout the manufacturing process.

Q3: What kind of warranty do you offer on your mesh products?

A3: We provide a comprehensive 1-year warranty against manufacturing defects for all our woven wire mesh products. This warranty covers material flaws and workmanship issues under normal operating conditions. Our commitment is to ensure products meet or exceed the agreed-upon specifications and performance standards.

Q4: Can you provide certification for material traceability or specific industry compliance?

A4: Yes, we provide full material traceability certificates (MTRs) for all our alloys and can furnish compliance documentation for various industry standards, including ISO, ASTM, DIN, and FDA requirements, upon request. Our quality assurance team ensures all relevant documentation is available to support your regulatory and auditing needs.

Our streamlined production and logistics ensure efficient order fulfillment. We maintain a robust inventory of common materials and mesh specifications, allowing for quick turnaround on standard orders. For custom or large-volume projects, a dedicated project manager will provide real-time updates on production status and estimated delivery, ensuring transparency and adherence to project timelines.

Our 1-year warranty reflects our confidence in the quality and durability of our square opening mesh. Should any product fail due to manufacturing defects within this period, we commit to repair, replace, or refund the item as per our terms and conditions. Our priority is your satisfaction and continuous operational success.

Our expert technical support team is available to assist you with product selection, technical queries, installation guidance, and any post-purchase concerns. We offer support via phone, email, and online inquiry forms. For urgent matters, a 24/7 emergency contact service is available to ensure minimal disruption to your operations. Our goal is to provide prompt, knowledgeable, and effective assistance at every stage.

RELATED PRODUCTS