Explore the cutting-edge world of Perforated Metal Mesh—technologies, trends, and industry-leading expertise from SHENZHOU TIKE METAL CO., LTD.

Explore the cutting-edge world of Perforated Metal Mesh—technologies, trends, and industry-leading expertise from SHENZHOU TIKE METAL CO., LTD.

SHENZHOU TIKE METAL CO., LTD. is a globally recognized manufacturer specializing in advanced architectural and industrial Perforated Metal Mesh. Established in Hebei, China, we combine innovation, top-grade materials, and efficient processes to provide customized solutions. Our mesh products deliver exceptional performance in numerous sectors—ensuring safety, durability, and aesthetics.

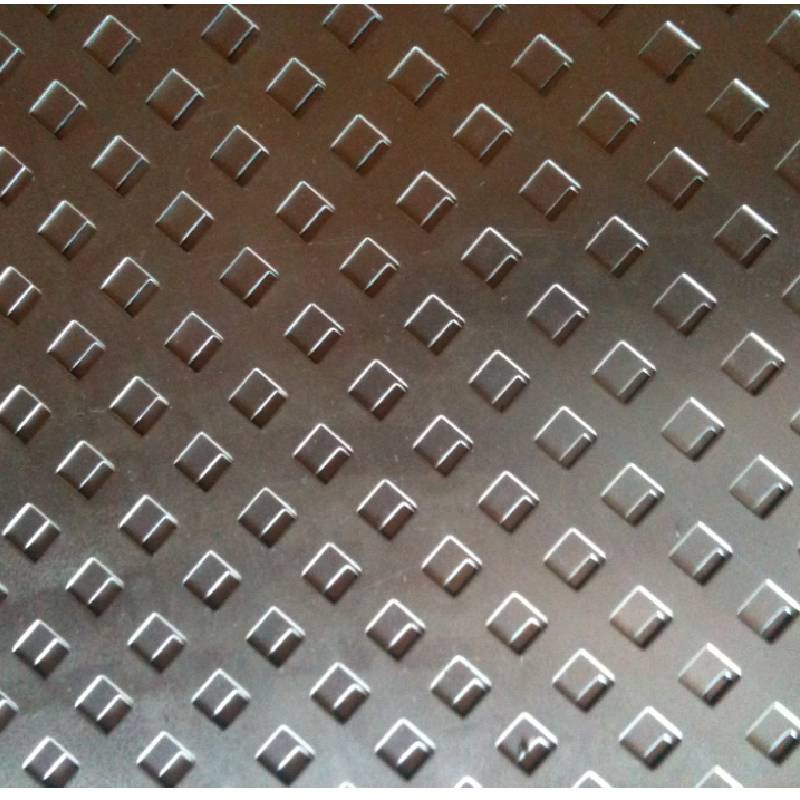

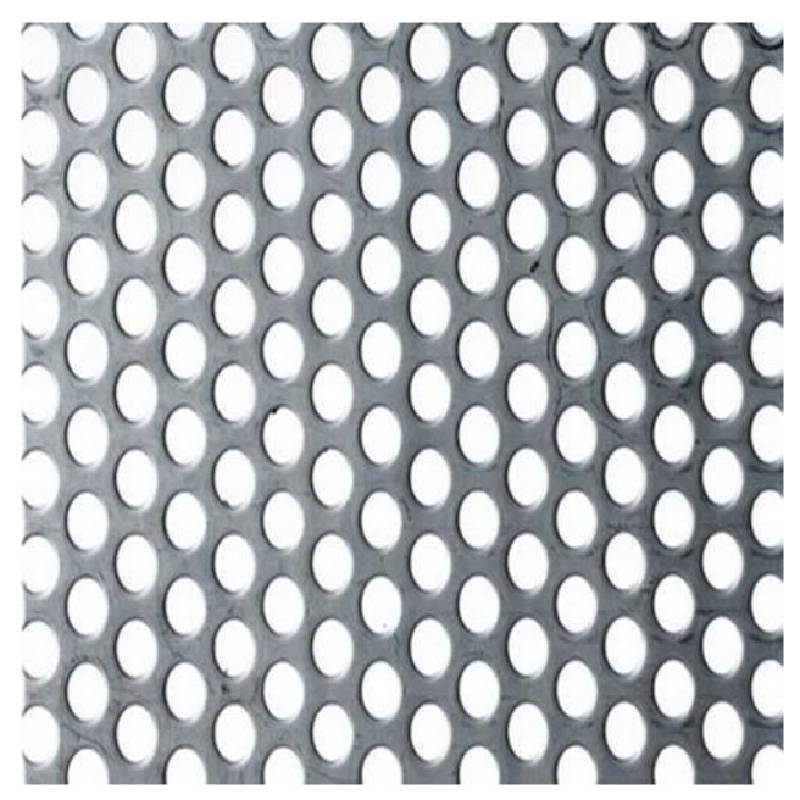

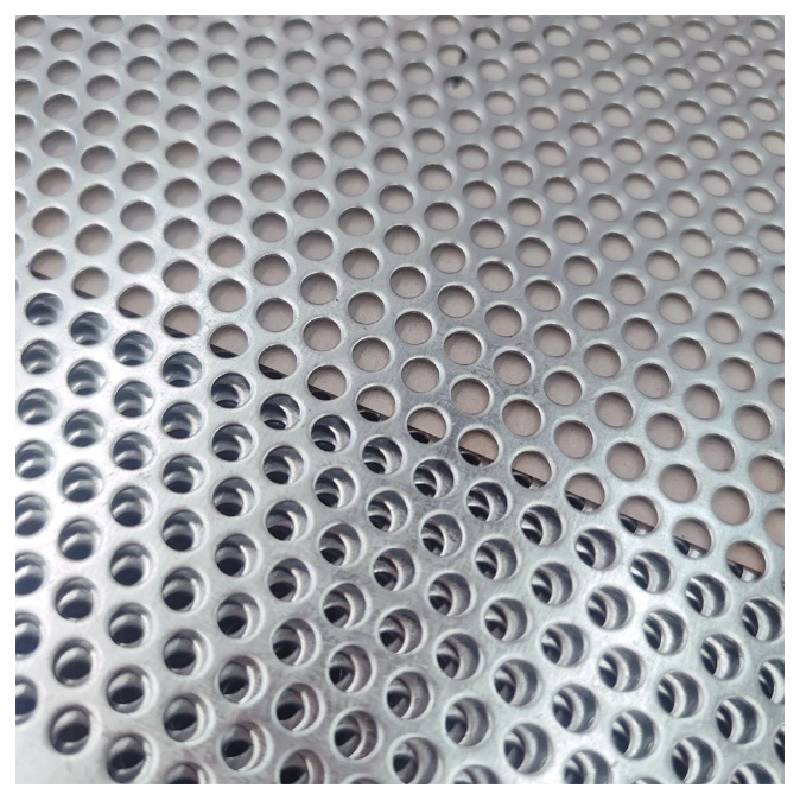

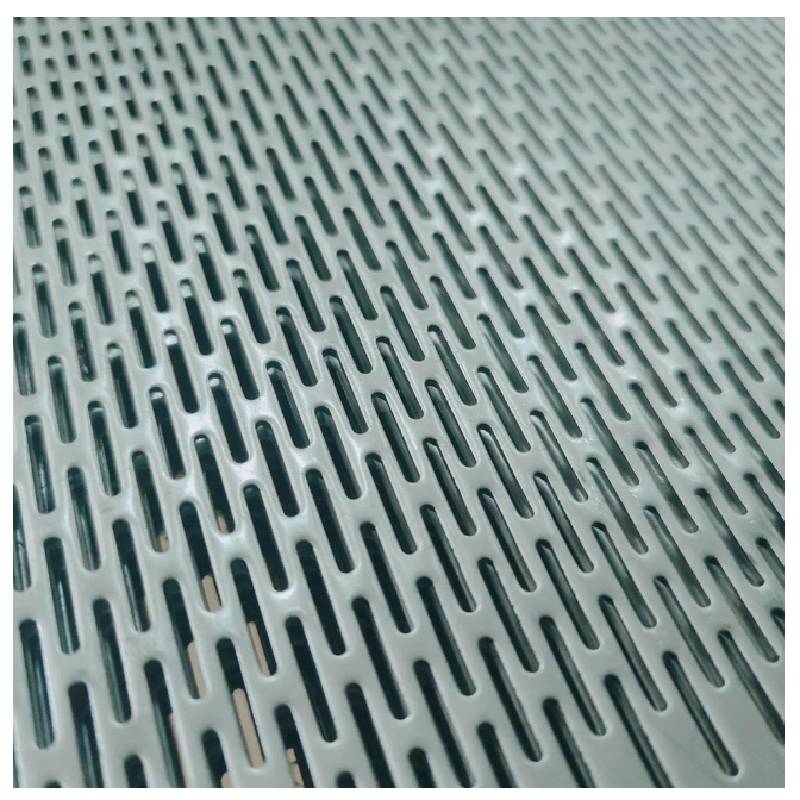

Perforated Metal Mesh refers to thin sheets of metal that have been mechanically punched, stamped, or laser cut to create a pattern of holes, slots, or decorative shapes. These meshes are characterized by their open area (opening rate), precise hole distribution, and versatile material selection. Used for over a century, Perforated Metal Mesh has evolved into a vital component across diverse architectural, industrial, and filtration applications.

The following table summarizes the core technical parameters of Perforated Metal Mesh widely referenced in the industry [Perforated Sheet Technology Data].

| Attribute | Description / Common Values |

|---|---|

| Materials | Stainless Steel, Mild Steel, Galvanized Steel, Aluminum, Brass, Copper |

| Thickness | 0.3mm – 12mm |

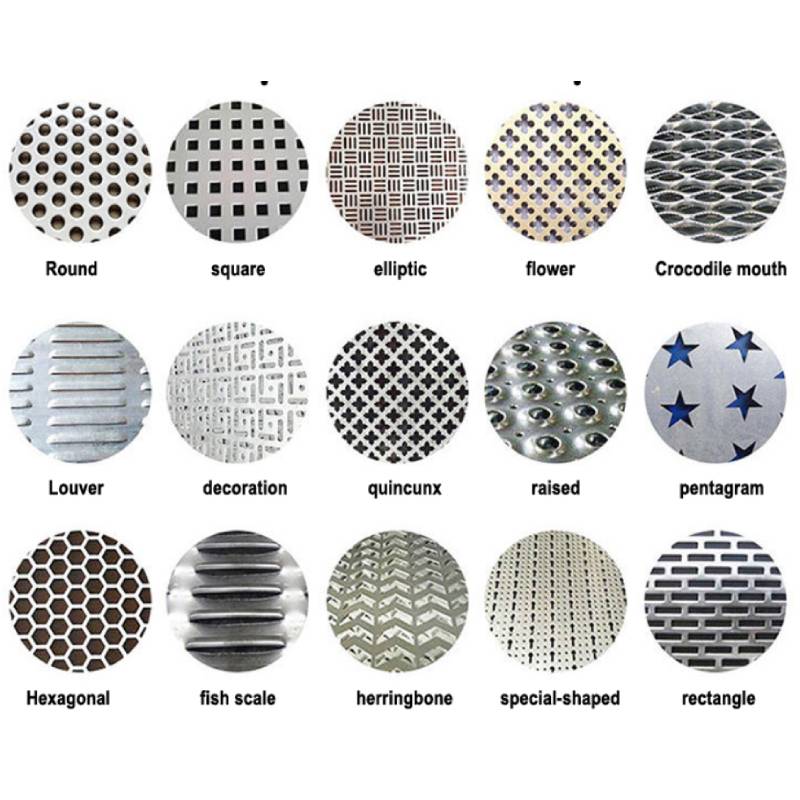

| Hole Shapes | Round, Square, Slot, Hexagonal, Decorative Patterns |

| Hole Size | 0.8mm – 100mm |

| Pitch (Center-to-center) | 1.5mm – 120mm |

| Open Area (Opening Rate) | 15% – 80% |

| Sheet Size | 1000mm × 2000mm, 1200mm × 2400mm, Customization available |

| Finishes | Mill, Powder coated, Anodized, Galvanized, PVDF coated |

| Standards | ISO 9001, ASTM, BS, EN |

The global Perforated Metal Mesh market exhibits robust growth, pushed by rising demand in architectural design, industrial filtration, noise control, and cladding. According to MarketsandMarkets, market size exceeded $13 billion in 2023, with double-digit growth forecast through 2030.

Key challenges remain in balancing strength with high opening rates and achieving corrosion protection—topics widely discussed in professional forums such as ENG-TIPS Metal and Metallurgy engineering forum.

More on application case studies can be accessed at Perforated Metal Mesh Product Page.

SHENZHOU TIKE METAL CO., LTD. delivers complete Perforated Metal Mesh solutions—from CAD design to on-site delivery. Our in-house engineering team assists with:

RELATED PRODUCTS