In the vast landscape of industrial and architectural materials, Perforated Metal Mesh stands out as a highly versatile and indispensable product. From its humble origins as a practical screening solution, it has evolved into a sophisticated engineering material, crucial across an array of sectors due to its unique combination of strength, permeability, and aesthetic appeal. This comprehensive guide delves into the intricate world of Perforated Metal Mesh, exploring its technical parameters, manufacturing prowess, diverse applications, and the critical factors that make it a cornerstone of modern construction and industry.

As a leading supplier, Tike Metal is committed to delivering high-quality Perforated Metal Mesh solutions tailored to specific project requirements. Our expertise ensures that every product not only meets but exceeds industry standards, offering unparalleled performance and durability.

The global market for Perforated Metal Mesh is experiencing steady growth, driven by increasing demand in construction, automotive, and environmental applications. According to market research, the global perforated metal market size was valued at approximately USD 2.2 billion in 2022 and is projected to reach USD 3.5 billion by 2030, with a Compound Annual Growth Rate (CAGR) of around 5.5% during the forecast period. This growth is significantly fueled by the rising adoption of sustainable building materials, the expansion of industrial infrastructure, and the growing focus on noise reduction and filtration systems.

The performance and suitability of Perforated Metal Mesh for any given application are primarily defined by its technical parameters. Understanding these specifications is crucial for optimal material selection and design.

Open Area = (Area of one hole * Number of holes per unit area) / Total unit area * 100%

For example, for a staggered round hole pattern, Open Area = (π * D² / 4) / (P * P * √3 / 2) * 100%, where D is hole diameter and P is pitch.| Parameter | Common Range/Values | Typical Applications |

|---|---|---|

| Material Types | Stainless Steel (304, 316), Carbon Steel, Aluminum, Galvanized Steel | Universal, depending on environment |

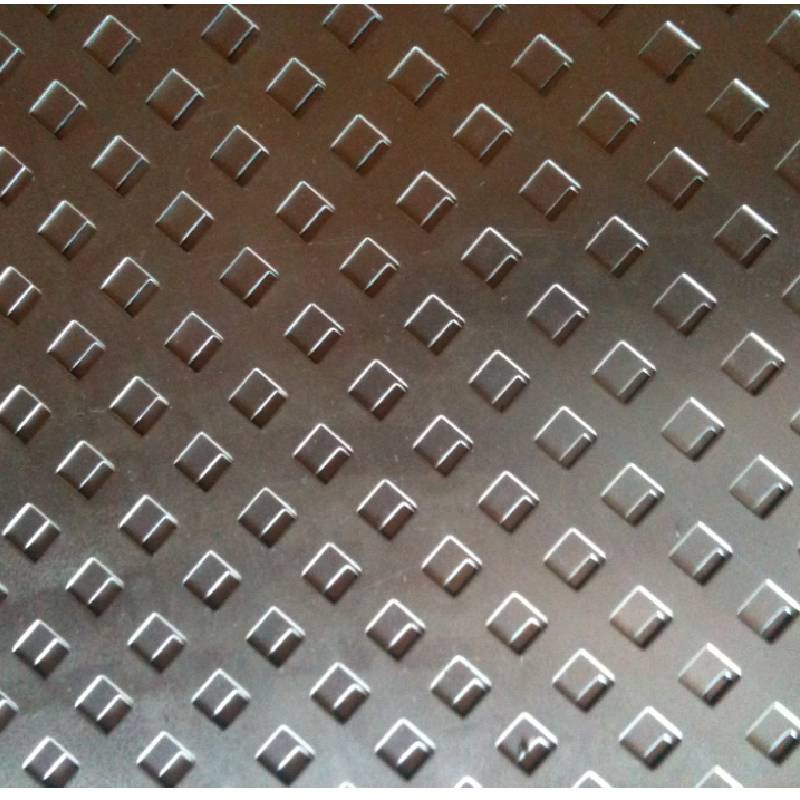

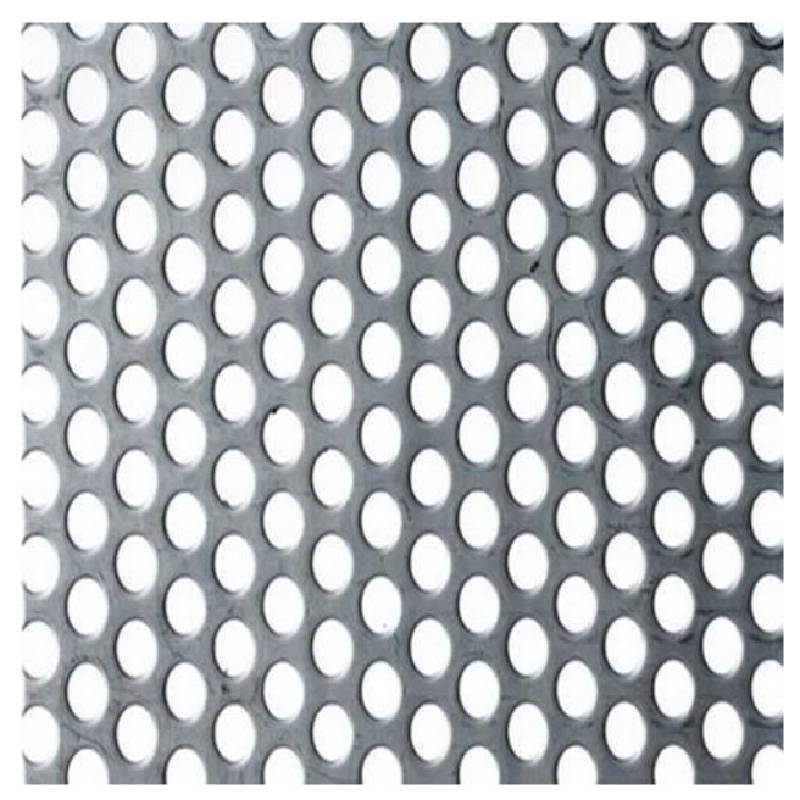

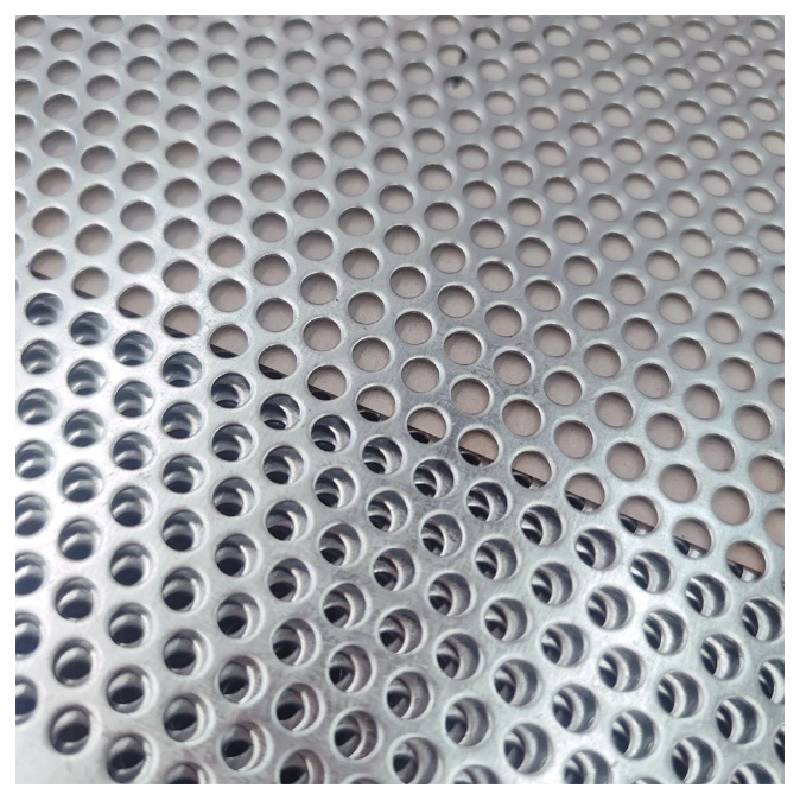

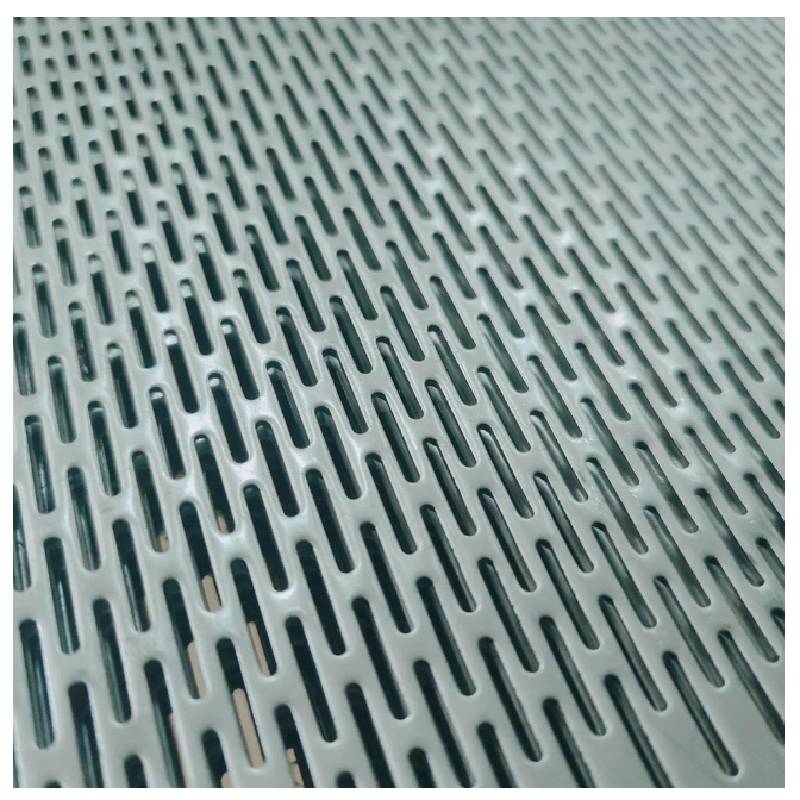

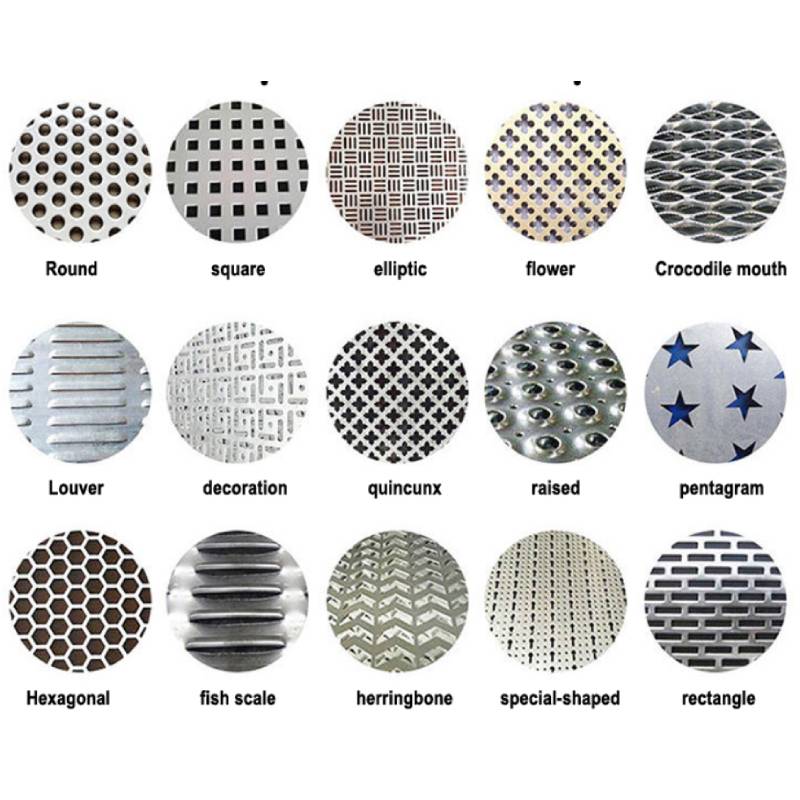

| Hole Shape | Round, Square, Slotted, Hexagonal | Filtration, Architectural, Guards, Screens |

| Hole Size (Diameter/Width) | 0.5 mm to 50 mm (0.02" to 2") | Fine filtration to heavy-duty screening |

| Pitch | 1.5 mm to 100 mm (0.06" to 4") | Dictates open area and pattern density |

| Open Area (%) | 20% to 60% (can range up to 80% for specific uses) | Ventilation (30-50%), Filtration (25-45%), Aesthetics (varied) |

| Gauge (Thickness) | 0.5 mm to 10 mm (24 gauge to 3/8 inch) | Lightweight panels to structural elements |

| Sheet Width | Up to 1.5 meters (60 inches) standard | Depends on manufacturing capabilities |

| Sheet Length | Up to 6 meters (240 inches) standard | Depends on manufacturing capabilities |

Tike Metal offers an extensive range of these parameters, ensuring that clients can find the perfect Perforated Metal Mesh solution for their precise needs.

The manufacturing of Perforated Metal Mesh is a precision-driven process that transforms raw metal sheets into highly functional and aesthetically pleasing products. While variations exist, the core process generally involves punching or stamping, followed by various finishing operations. Tike Metal adheres to stringent quality control throughout this process, ensuring compliance with international standards such as ISO 9001, ASTM (American Society for Testing and Materials), and ANSI (American National Standards Institute) for dimensions, material specifications, and quality. Our products typically boast a service life exceeding 20 years under normal conditions, thanks to superior material quality and manufacturing precision.

The process begins with selecting the appropriate raw metal coil or sheet (e.g., stainless steel, carbon steel, aluminum) based on the client's specifications for material type, thickness, and grade. The material is then loaded onto specialized machinery, often as large coils to facilitate continuous production.

This is the core of the process. High-speed punching presses equipped with custom tooling (dies and punches) accurately perforate the metal sheet. The tooling is designed to create specific hole shapes, sizes, and patterns (straight, staggered, decorative). Modern CNC (Computer Numerical Control) technology ensures extreme precision, allowing for complex designs and minimizing material waste. The material is fed through the machine, and thousands of holes are punched per minute.

After perforation, the sheet may experience some distortion or camber due to the stress exerted during the punching process. It undergoes a leveling process where it passes through a roller leveler to restore its flatness and ensure it meets strict industry flatness tolerances, typically within +/- 2mm over 3 meters.

The punching process can leave small burrs or sharp edges around the perforations. The deburring stage removes these imperfections, creating a smooth and safe surface. This can be done mechanically (brushing, tumbling) or chemically, depending on the material and application.

The continuous perforated sheet is then cut into the specified final dimensions (sheets, panels, or custom shapes) using precision shearing machines or laser cutters. This ensures accurate sizing for subsequent fabrication or direct use.

Depending on the application, the Perforated Metal Mesh may undergo further surface treatments to enhance its durability, corrosion resistance, or aesthetic appeal. Common finishes include:

Throughout the entire process, rigorous quality checks are performed. This includes visual inspection for defects, measurement of hole size, pitch, and sheet dimensions, open area verification, and material composition analysis. Products are inspected to meet client specifications and international standards like ISO 9001:2015, ensuring consistent quality and performance. Only products passing these stringent checks are approved for packaging and dispatch.

The remarkable versatility of Perforated Metal Mesh makes it indispensable across a multitude of industries. Its ability to filter, ventilate, diffuse, protect, and decorate positions it as a go-to material for innovative solutions.

Tike Metal’s products are trusted in diverse sectors including:

The widespread adoption of Perforated Metal Mesh is a testament to its compelling technical advantages:

Selecting the right manufacturer for your Perforated Metal Mesh needs is paramount to project success. While many suppliers exist, Tike Metal distinguishes itself through a commitment to quality, deep industry expertise, and unparalleled customer support.

Understanding that every project is unique, Tike Metal specializes in providing bespoke Perforated Metal Mesh solutions:

At Tike Metal, trustworthiness is built on a foundation of rigorous quality assurance, transparent commitments, and dedicated customer support. We understand that our clients rely on our products for critical applications, and we stand behind every piece of Perforated Metal Mesh we deliver.

Tike Metal offers a comprehensive product warranty against defects in materials and workmanship. The specific warranty period varies depending on the product type and application but typically extends for 1 to 5 years from the date of purchase. Our goal is to ensure client satisfaction and the long-term performance of our Perforated Metal Mesh solutions. Details of our warranty policy are available upon request.

We work with trusted logistics partners to ensure safe and timely delivery of your Perforated Metal Mesh. Products are carefully packaged to prevent damage during transit, whether by sea, air, or land. We provide tracking information and work closely with clients to manage delivery schedules effectively.

Our dedicated customer support team is available to assist with any inquiries, from initial project consultation and technical specifications to after-sales support. We believe in building long-term partnerships, providing expert advice, and ensuring a seamless experience throughout the project lifecycle. Reach out to us via phone, email, or our website for prompt assistance.

A1: Open area refers to the total percentage of the sheet that has been removed by the perforations. It's a critical factor determining the mesh's flow rate (for liquids or air), light transmission, and acoustic properties. A higher open area generally means more flow but less strength.

A2: Stainless steel (304, 316), carbon steel, aluminum, and galvanized steel are most common. The choice depends on the application's environment (corrosion risk), required strength, weight constraints, and budget. For instance, stainless steel 316 is preferred for marine or highly corrosive chemical environments, while aluminum is ideal where lightweight and good corrosion resistance are needed.

A3: Yes, Perforated Metal Mesh can be bent, rolled, or formed into various shapes. However, the minimum bending radius and formability depend on the material thickness, hole pattern, and open area. It's advisable to consult with the manufacturer during the design phase for complex forming requirements.

A4: Key standards include ISO 9001 (Quality Management Systems), ASTM (e.g., ASTM E2016 for Industrial Perforated Plate and Screens), and ANSI. These standards cover material specifications, dimensions, tolerances, and testing procedures to ensure product quality and performance.

A5: Cost is primarily influenced by material type and thickness, complexity of the hole pattern, open area percentage, sheet size, quantity ordered, and any special finishing requirements (e.g., powder coating). Custom tooling for unique patterns can also add to the initial cost.

A6: The lifespan of Perforated Metal Mesh varies significantly based on the material, environmental conditions, and application. High-grade stainless steel or aluminum with proper finishes can last for decades (20+ years) in many outdoor or industrial settings. Carbon steel without protective coating will have a shorter life. Regular maintenance can also extend its service life.

A7: Yes, many manufacturers, including Tike Metal, offer extensive customization capabilities. Using advanced CNC punching technology, intricate custom hole patterns, company logos, or decorative designs can be incorporated into the Perforated Metal Mesh, making it ideal for unique architectural features or branding.

As industries continue to evolve, the demand for materials that offer a perfect blend of functionality, aesthetics, and sustainability will only grow. Perforated Metal Mesh, with its inherent versatility and adaptable properties, is perfectly positioned to meet these demands. From enhancing energy efficiency in smart buildings to ensuring precise filtration in critical industrial processes, its applications are as limitless as human ingenuity.

At Tike Metal, we are proud to be at the forefront of this industry, committed to pushing the boundaries of what's possible with Perforated Metal Mesh. Our dedication to quality, precision engineering, and customer satisfaction ensures that we provide solutions that not only perform but also inspire. Whether for a groundbreaking architectural project or a vital industrial application, the future is indeed perforated.

For detailed market insights, you may refer to reports from reputable market research firms. For example, the "Perforated Metal Market Size, Share & Trends Analysis Report" from Grand View Research provides an excellent overview of market dynamics and forecasts (e.g., search "Grand View Research Perforated Metal Market Report").

For technical specifications and quality control, consult official publications from organizations like ASTM International and ISO.

Online forums and professional communities often discuss practical applications and challenges of perforated metal. Examples include forums related to architectural design, HVAC, or general metal fabrication (e.g., search "ArchDaily Perforated Metal" or "Engineering Forum Perforated Mesh").

For in-depth studies on material properties, acoustic performance, and structural analysis of perforated materials, scholarly databases like ScienceDirect or IEEE Xplore can be valuable resources (e.g., search "perforated metal acoustic performance research").

RELATED PRODUCTS