Perforated wire mesh stands as a pivotal product in numerous industries, offering unparalleled versatility and reliability. With extensive experience and practical insights into this domain, we delve into the intricacies of perforated wire mesh to provide a comprehensive resource that benefits both seasoned professionals and newcomers alike.

Perforated wire mesh is a type of sheet metal that has been manually or mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes. This structure not only lends it a unique aesthetic appeal but also enhances its functionality across a wide array of applications such as filtration, screening, soundproofing, and numerous architectural solutions.

The journey with perforated mesh begins with selecting the right material. Stainless steel remains a favorite due to its corrosion resistance, strength, and durability under various environmental conditions. However, for projects demanding cost-efficiency without a compromise on sturdiness, aluminum or galvanized steel may be preferred. Choosing the right material can significantly impact the longevity and performance of the mesh in its intended application.

The hole pattern and size are equally crucial, influencing the mesh's strength, weight, and screening capabilities. Round holes are the most common, offering a good balance between open area and structural integrity. For applications that need more open space, such as insect screening or ventilation, square or slotted holes might be preferable. Understanding the specific requirements of your project will guide you in picking the most suitable configuration.

Installation and maintenance of perforated wire mesh are critical for maximizing its lifespan. Proper handling during installation ensures that the mesh retains its shape and function. Regular inspection for signs of wear or damage, especially in high-stress environments, prevents premature failures. Ensuring that the mesh is free from debris and maintaining the integrity of the protective coatings prolongs its service life.

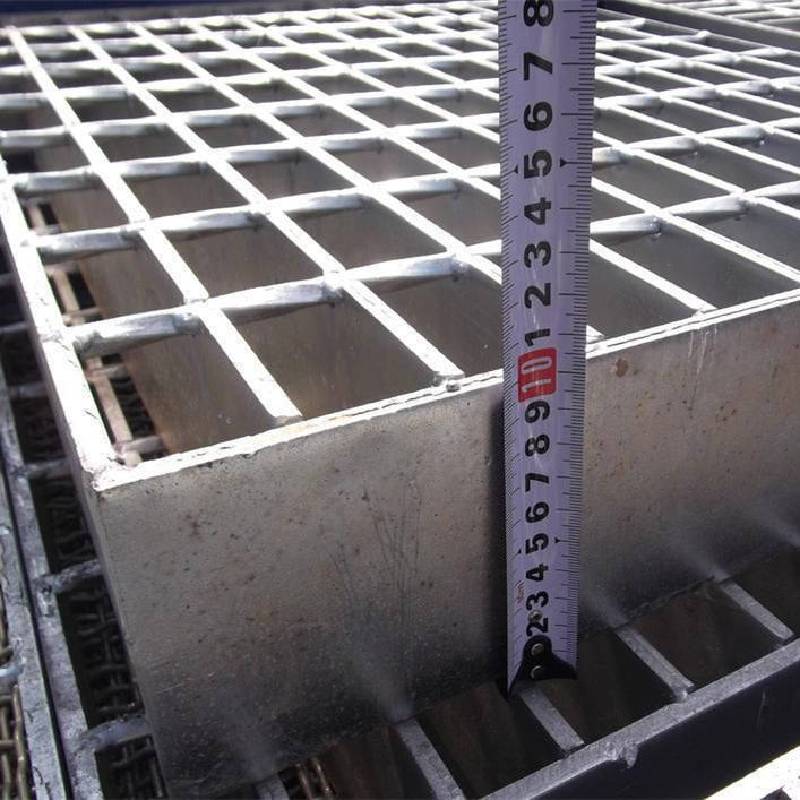

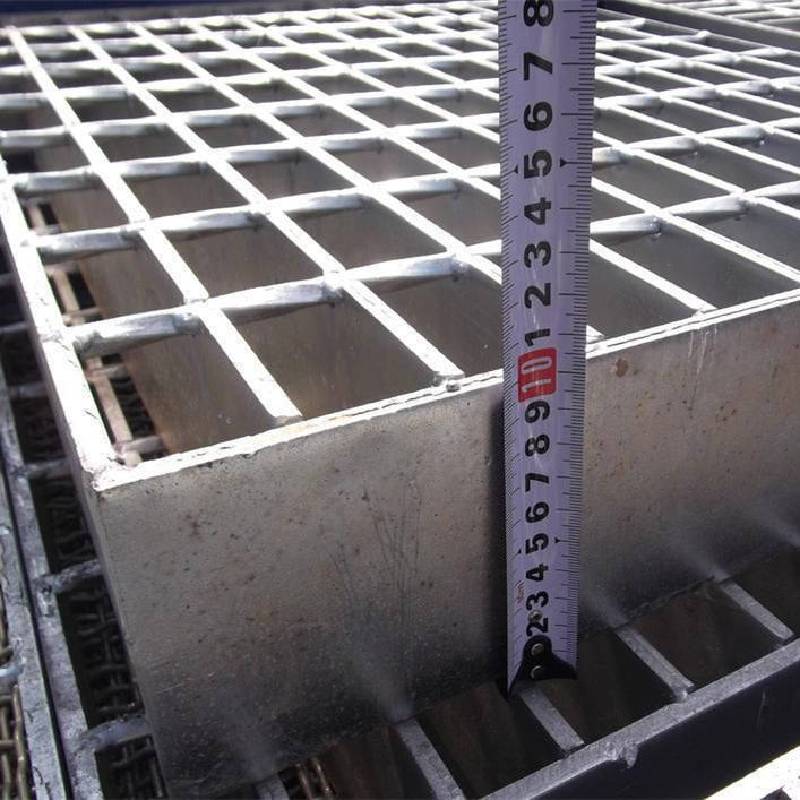

perforated wire mesh

Our expertise extends into tailored solutions, where we customize perforated wire mesh to meet unique client demands, whether it's a specific pattern, a particular grade of material, or a bespoke design that complements an architectural vision. Our authority in the field is rooted in years of hands-on experience, backed by a dedicated team that continuously researches to improve and innovate.

Trustworthiness is built through delivering consistent quality and aligning with international standards. Our perforated wire mesh products undergo rigorous testing to ensure they meet the highest standards of performance and safety. These quality checks encompass tensile strength assessments, corrosion resistance tests, and dimensional accuracy verifications, giving our clients peace of mind.

In niche applications such as soundproofing, perforated mesh functionally balances aesthetics and performance. The strategic arrangement of perforations can help attenuate noise, making them ideal for use in acoustic panels or within buildings requiring insulation from external sounds.

The sustainability of perforated wire mesh is another reason for its increasing popularity. With a rising awareness towards sustainable construction practices, the recyclability and energy-efficient production processes associated with metal mesh align well with green building standards, including LEED certification goals. Beyond just providing exceptional functional benefits, perforated wire mesh supports a responsible approach to modern construction and manufacturing practices.

In conclusion, perforated wire mesh is an indispensable resource for innovators and builders, offering unmatched utility and adaptability. With our extensive expertise and authoritative approach, clients are assured of premium products that stand the test of time, backed by a commitment to quality and sustainability. Whether it’s enhancing the aesthetic appeal of a building or creating a robust industrial filtration system, perforated wire mesh emerges as a champion choice. As industry leaders, we remain dedicated to advancing this versatile material, continually exploring new applications and improving existing solutions.