Perforated metal mesh is a versatile and durable material that has become a cornerstone in modern industrial and architectural applications. With its unique combination of high opening rate, corrosion resistance, and customizable design, this material is engineered to meet the demands of diverse industries. Shenzhou Tike Metal Co., Ltd., a leading manufacturer in the field, offers a range of perforated metal products that combine innovation with reliability. This article explores the features, technical specifications, and real-world applications of Perforated Metal Mesh, while highlighting the company's commitment to quality and sustainability.

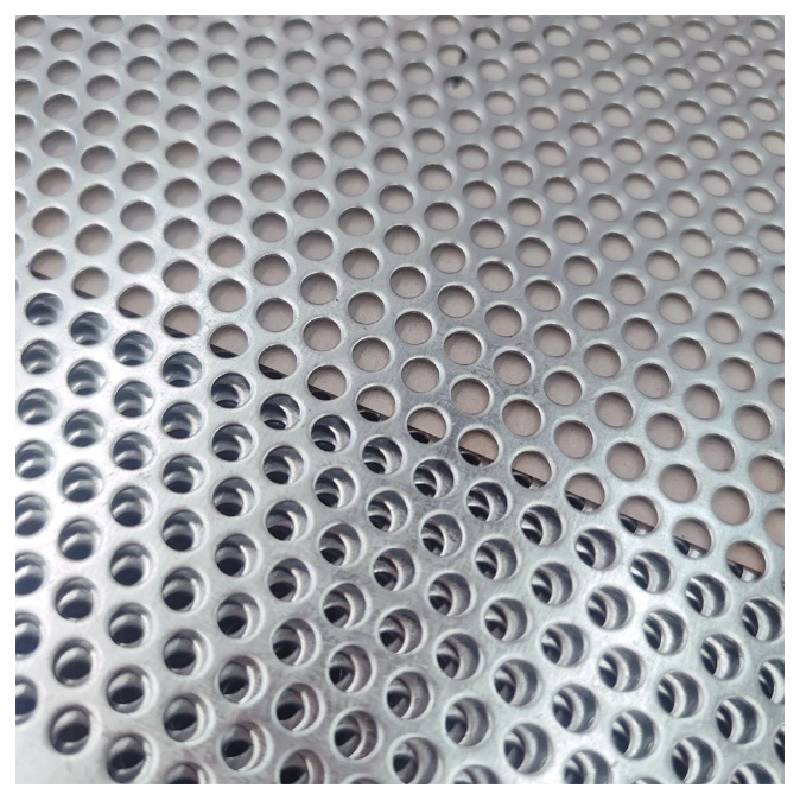

High Opening Rate is one of the most distinctive characteristics of perforated metal mesh. The opening rate can exceed 30%, allowing for exceptional airflow and light transmission. This feature makes it ideal for applications requiring ventilation, filtration, and sound control. For instance, in industrial settings, the high opening rate ensures efficient air circulation, reducing the risk of overheating and improving operational safety. In architectural contexts, it allows natural light to penetrate spaces, reducing the need for artificial lighting and enhancing energy efficiency.

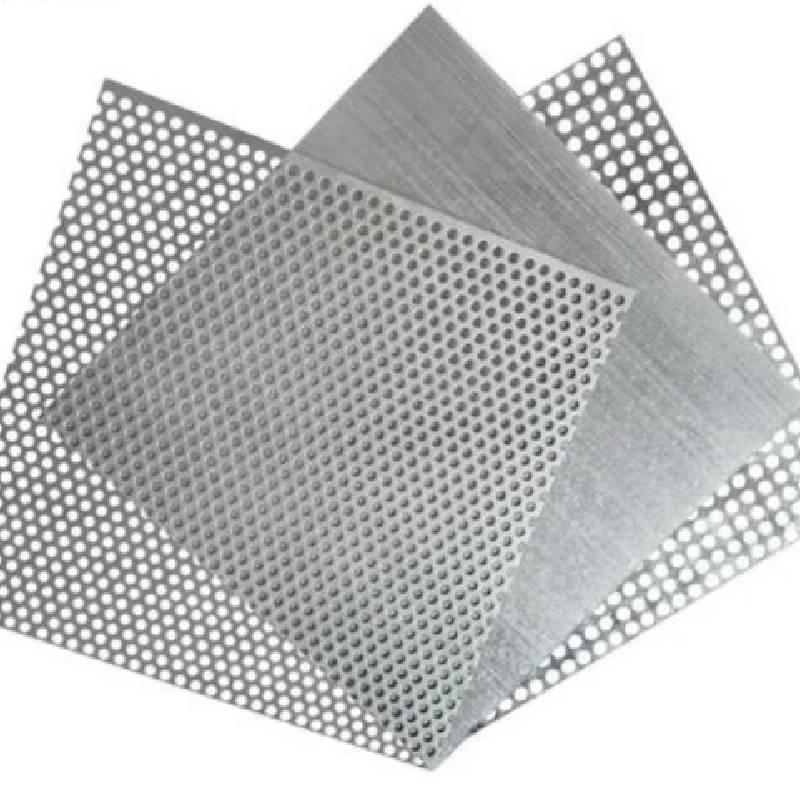

Lightweight Design is another significant advantage. Due to the high opening rate, perforated metal mesh is significantly lighter than solid metal sheets of the same dimensions. This reduces transportation costs and makes installation more manageable, particularly in large-scale projects. The lightweight nature also contributes to structural efficiency, making it a preferred choice for applications where weight is a critical factor.

Corrosion Resistance is a critical feature that ensures the longevity of perforated metal mesh. The material can be manufactured from various metals, including stainless steel, aluminum, and galvanized steel, each offering different levels of resistance to environmental factors. This makes the mesh suitable for both indoor and outdoor applications, even in harsh conditions. For example, in coastal areas where saltwater exposure is common, corrosion-resistant perforated metal mesh can withstand the elements without compromising structural integrity.

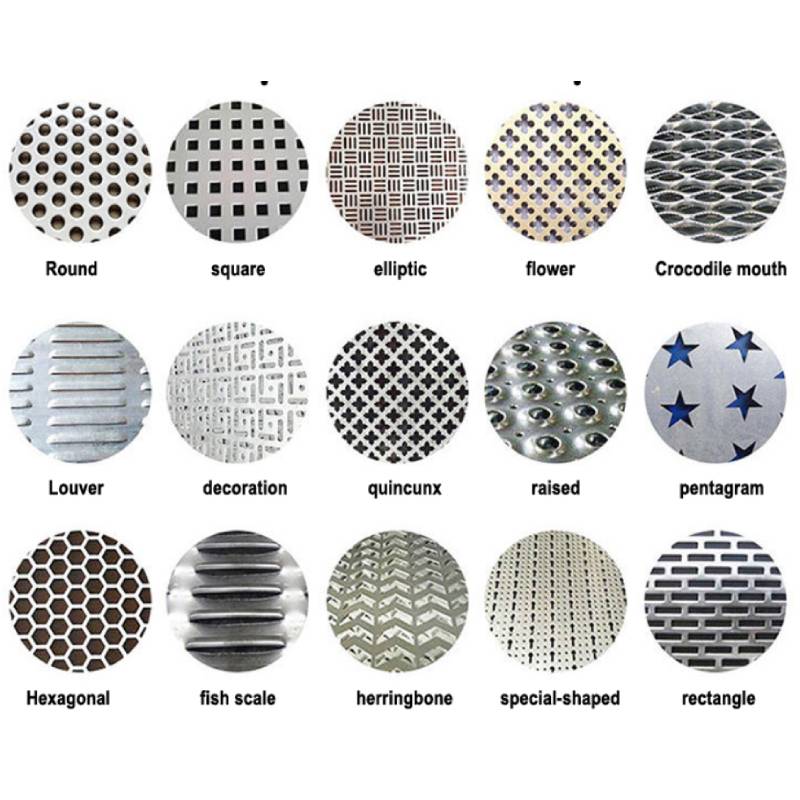

Customizable Aesthetics set perforated metal mesh apart from conventional materials. The mesh can be produced in a variety of shapes, including square, round, and oval, allowing for creative design possibilities. This flexibility is particularly valuable in architectural projects where visual appeal is as important as functionality. Whether it's a modern office building or a historical restoration, the ability to customize the mesh ensures that it complements the overall design.

Easy Processing further enhances the versatility of perforated metal mesh. The material can be cut, bent, welded, and shaped to fit specific requirements. This adaptability makes it a popular choice for manufacturers and engineers who need to integrate the mesh into complex systems. Additionally, the ease of processing reduces production time and costs, making it a cost-effective solution for various industries.

Environmental Sustainability is a growing concern in modern manufacturing, and perforated metal mesh addresses this issue effectively. The material is fully recyclable, reducing waste and promoting a circular economy. By choosing perforated metal mesh, businesses can align with eco-friendly practices while maintaining high performance standards. This sustainability aspect is particularly appealing to industries looking to reduce their carbon footprint and meet regulatory requirements.

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

Industrial Applications are one of the primary uses of perforated metal mesh. The material is extensively used in oil filters and grain sifters, where its high opening rate and durability ensure efficient separation of materials. In the automotive industry, perforated metal mesh is employed in sound isolation systems to reduce noise pollution and enhance driver comfort. Additionally, its corrosion resistance makes it suitable for use in chemical processing plants, where exposure to harsh chemicals is common.

Architectural Applications highlight the aesthetic and functional benefits of perforated metal mesh. The material is used in ventilation systems to improve indoor air quality, as well as in acoustic panels to control sound reverberation in large spaces. In modern architecture, perforated metal mesh is often integrated into building facades to create visually striking designs while maintaining structural integrity. Its ability to allow natural light to pass through also contributes to energy efficiency, reducing the need for artificial lighting.

Other Applications include the production of screening devices for agricultural and mining industries, where the mesh's durability and high opening rate ensure efficient material handling. In the entertainment sector, perforated metal mesh is used in stage backdrops and soundproofing panels, providing both functionality and visual appeal. The versatility of the material makes it a valuable asset across multiple sectors.

Shenzhou Tike Metal Co., Ltd., based in Shenzhou, China, has established itself as a reliable supplier of high-quality Perforated Metal Mesh. With years of experience in the industry, the company has built a reputation for delivering products that meet the highest standards of performance and durability. Their commitment to innovation and customer satisfaction is evident in their comprehensive range of products, which cater to a wide array of applications.

The company's state-of-the-art manufacturing facilities ensure precision and consistency in every product. By leveraging advanced technologies and rigorous quality control measures, Shenzhou Tike Metal Co., Ltd. guarantees that their perforated metal mesh meets the specific requirements of each client. This dedication to quality is further reinforced by their adherence to international standards, including those set by the National Institute of Standards and Technology (NIST), which plays a pivotal role in advancing measurement science and technology in the United States.

Shenzhou Tike Metal Co., Ltd. also emphasizes sustainability in its operations. The company's focus on recyclable materials and energy-efficient production processes aligns with global efforts to reduce environmental impact. By choosing their products, businesses can contribute to a more sustainable future while benefiting from the superior performance of perforated metal mesh.

One notable application of perforated metal mesh is in the construction of green buildings, where the material's ability to enhance natural lighting and ventilation is leveraged to reduce energy consumption. For example, the NIST has recognized the importance of materials like perforated metal mesh in achieving energy efficiency in modern architecture. Their research on sustainable building practices highlights the role of such materials in creating environmentally friendly structures.

Another case study involves the use of perforated metal mesh in industrial filtration systems. A leading manufacturer of oil filtration equipment integrated perforated metal mesh into their products, resulting in improved efficiency and reduced maintenance costs. The material's high opening rate and corrosion resistance ensured that the filters could handle demanding conditions without compromising performance.

In the entertainment industry, perforated metal mesh has been used to create innovative stage designs. For instance, a renowned theater company utilized the material in their latest production to achieve a unique visual effect while maintaining acoustic control. The mesh's ability to allow light to pass through and absorb sound made it an ideal choice for the project.

Perforated Metal Mesh is a versatile and durable material that offers a wide range of benefits for industrial and architectural applications. Its high opening rate, lightweight design, corrosion resistance, customizable aesthetics, and environmental sustainability make it a preferred choice for businesses seeking reliable solutions. Shenzhou Tike Metal Co., Ltd. continues to lead the industry with its commitment to quality, innovation, and sustainability. By integrating perforated metal mesh into their projects, companies can enhance performance, reduce costs, and contribute to a more sustainable future.

1. National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

2. Shenzhou Tike Metal Co., Ltd. (n.d.). Perforated Metal Mesh. Retrieved from https://www.tikemetal.com/perforated-metal-mesh.html

RELATED PRODUCTS