Perforated metal mesh is a versatile and durable material that has become an essential component in various industries and architectural applications. Its unique combination of high opening rate, lightweight design, and corrosion resistance makes it a preferred choice for engineers, architects, and manufacturers worldwide. This article explores the features, technical specifications, application scenarios, and company background of Perforated Metal Mesh offered by Shenzhou Tike Metal Co., Ltd., a leading manufacturer in this field.

Perforated Metal Mesh is engineered to deliver exceptional performance across a wide range of applications. One of its most notable features is its high opening rate, which can exceed 30%. This allows for excellent air permeability and light transmission, making it ideal for ventilation systems, soundproofing, and decorative panels. The high opening rate also contributes to the lightweight design of the mesh, as it reduces the overall weight compared to solid metal sheets of the same size. This characteristic is particularly beneficial in applications where weight reduction is critical, such as in aerospace or automotive industries.

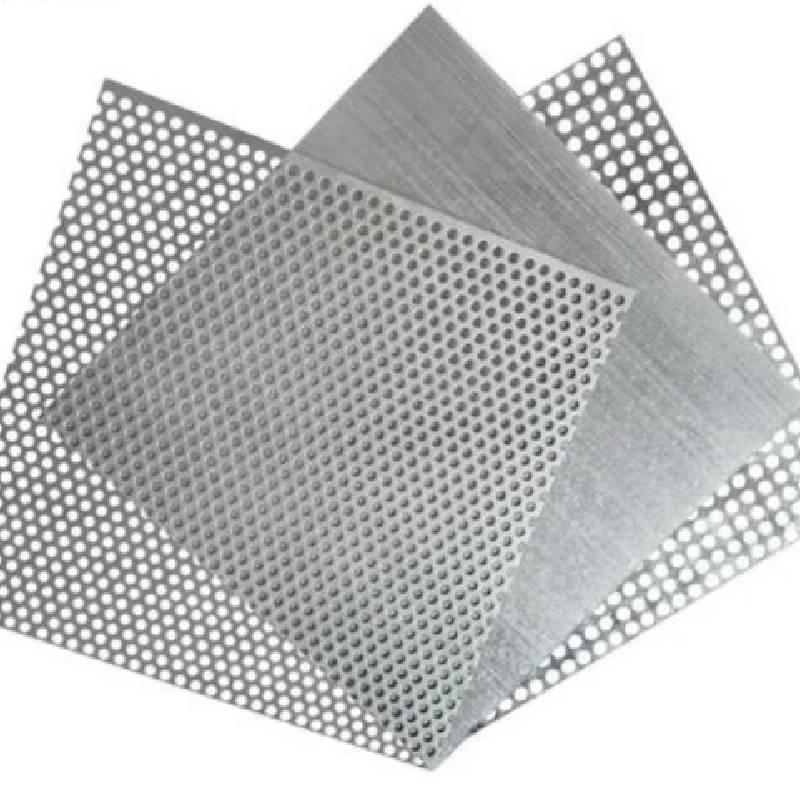

Another standout feature is its corrosion resistance. Perforated mesh can be manufactured from various metal alloys, including stainless steel, aluminum, and galvanized steel, each offering different levels of corrosion resistance depending on the application requirements. This durability ensures the material can withstand harsh environments, such as industrial settings or coastal regions, without compromising its structural integrity.

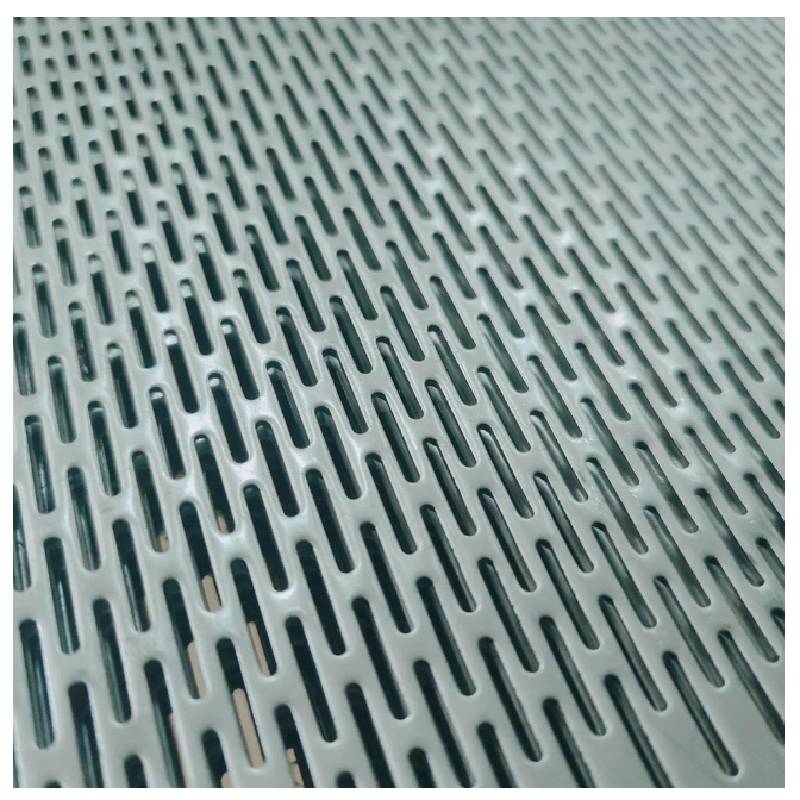

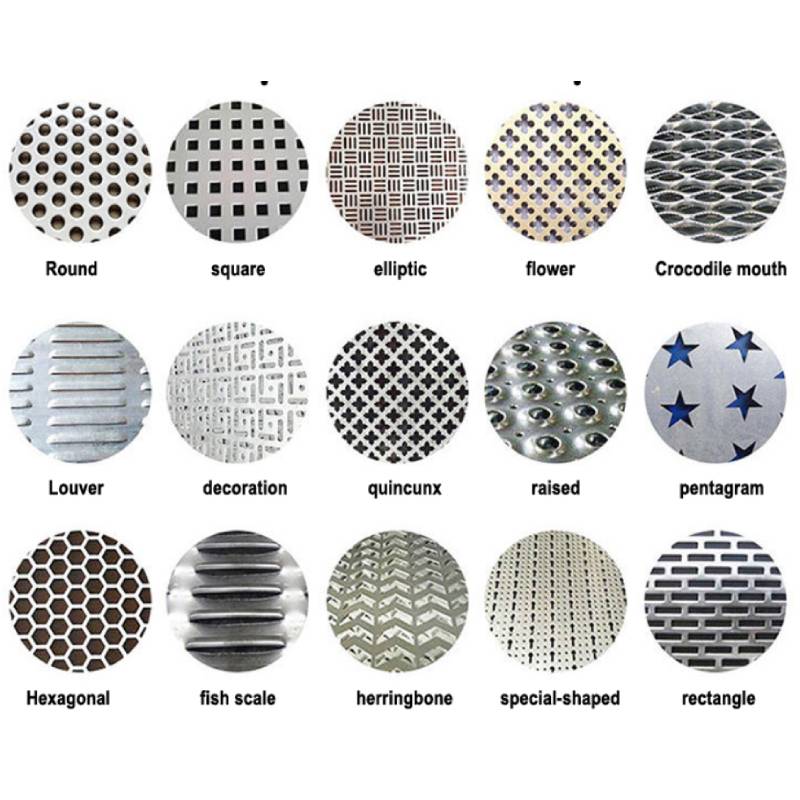

The customizable design of Perforated Metal Mesh is another significant advantage. The opening shape can be tailored to meet specific customer needs, enabling the creation of intricate patterns and shapes. This flexibility allows architects and designers to incorporate the mesh into aesthetic elements of buildings, such as facades, partitions, and ceiling systems. Additionally, the easy processing capabilities of the material—enabling cutting, bending, welding, and other modifications—further enhance its adaptability to diverse projects.

Environmental sustainability is also a key consideration. The recyclability of Perforated Metal Mesh makes it an eco-friendly option for manufacturers and consumers alike. By reusing the material, industries can reduce waste and contribute to a circular economy. This aligns with global efforts to minimize environmental impact while maintaining high performance standards.

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm–10mm |

| Opening Rate | 5%–80% |

| Aperture | 0.5mm–200mm |

| Hole Distance | 1mm–200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150–200HB/30–50HB |

| Area Density | 20%–60% |

The technical specifications of Perforated Metal Mesh highlight its versatility and performance capabilities. The material's thickness ranges from 0.3mm to 10mm, allowing it to be used in both lightweight and heavy-duty applications. The opening rate can be adjusted between 5% and 80%, providing flexibility for different functional requirements, such as filtration, sound absorption, or decorative purposes. The aperture and hole distance are customizable, enabling precise control over airflow, light transmission, and structural strength.

The size options ensure compatibility with standard manufacturing processes and construction projects. Common dimensions include 1m x 2m, 1.22m x 2.44m, and 1.5m x 3m, which are widely used in industrial and architectural contexts. The shape of the holes—whether square, round, or oval—can be tailored to specific design or performance needs. For example, round holes are often preferred for their uniformity and ease of manufacturing, while square or oval holes may be chosen for aesthetic or functional reasons.

The tensile strength and hardness of the material ensure durability and resistance to deformation under stress. The area density (20%–60%) further influences the mesh's weight and structural integrity, making it suitable for applications requiring a balance between strength and lightness.

Perforated Metal Mesh is widely used in both industrial and architectural applications. In industrial settings, it serves as a critical component in oil filters, grain sifters, and sound isolation systems. Its high opening rate and air permeability make it ideal for filtration and ventilation, while its corrosion resistance ensures long-term performance in harsh environments. For example, in sound isolation, the mesh can be used to absorb or block noise, improving acoustic comfort in industrial facilities and commercial buildings.

In architectural applications, Perforated Metal Mesh is employed for ventilation systems, decorative panels, and structural elements. Its customizable design allows architects to integrate the material into modern building facades, interior partitions, and ceiling systems. The lightweight nature of the mesh also makes it suitable for large-scale installations without adding excessive structural load. Additionally, its aesthetic appeal enables the creation of visually striking designs that combine functionality with artistic expression.

One of the most popular variations of Perforated Metal Mesh is the round hole perforation, which is favored for its uniformity and ease of manufacturing. This type is commonly used in air filters, grilles, and decorative elements. However, other shapes, such as square or oval holes, are also available to meet specific design or performance requirements.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of Perforated Metal Mesh and other metal products, with a strong reputation for quality, innovation, and customer service. The company specializes in producing high-performance metal mesh solutions tailored to the needs of various industries. With years of experience in the field, Shenzhou Tike Metal has established itself as a trusted partner for manufacturers, architects, and engineers seeking reliable and durable materials.

The company's commitment to technical excellence is evident in its advanced manufacturing processes and rigorous quality control standards. By leveraging state-of-the-art machinery and skilled professionals, Shenzhou Tike Metal ensures that its products meet the highest industry benchmarks. This dedication to quality is reflected in the corrosion resistance, durability, and customization options offered by its Perforated Metal Mesh products.

As a manufacturer with a global presence, Shenzhou Tike Metal serves clients across multiple regions, providing customized solutions that address specific application requirements. The company's environmental responsibility is also a key focus, with initiatives aimed at reducing waste and promoting sustainable practices. This aligns with the growing demand for eco-friendly materials in both industrial and architectural sectors.

There are several compelling reasons to choose Shenzhou Tike Metal Co., Ltd. for your Perforated Metal Mesh needs. First and foremost is the superior quality of the products. The company's perforated metal mesh is manufactured using high-grade materials and advanced techniques, ensuring durability, corrosion resistance, and precision in every component. This makes it suitable for demanding applications where reliability is critical.

Another key advantage is the customization options available. Shenzhou Tike Metal understands that each project has unique requirements, and the company offers tailored solutions to meet these needs. Whether you require a specific opening rate, aperture size, or shape, the team can work closely with you to design the perfect perforated metal mesh for your application.

The company's competitive pricing and efficient delivery further enhance its appeal. By optimizing its production processes and supply chain, Shenzhou Tike Metal ensures that customers receive high-quality products at cost-effective prices. This is particularly beneficial for businesses looking to reduce expenses without compromising on quality.

Finally, Shenzhou Tike Metal provides comprehensive customer support, from initial consultation to post-sale services. The company's team of experts is dedicated to helping clients make informed decisions and ensuring that their projects are completed successfully. This level of support is invaluable in complex or large-scale applications.

As a manufacturer of Perforated Metal Mesh, Shenzhou Tike Metal Co., Ltd. adheres to international industry standards and certifications to ensure the quality and performance of its products. These standards include ISO 9001 for quality management, ISO 14001 for environmental management, and ASME for material specifications. Compliance with these standards guarantees that the perforated metal mesh meets the highest levels of technical performance and safety.

For further information on industry standards related to perforated metal mesh, you can refer to the National Institute of Standards and Technology (NIST), which provides comprehensive resources on materials and manufacturing processes. NIST plays a critical role in developing standards that ensure the reliability and performance of industrial materials, including metal mesh products.

Perforated Metal Mesh is a versatile and high-performance material that offers numerous benefits for industrial and architectural applications. Its high opening rate, lightweight design, corrosion resistance, and customizable features make it an ideal choice for a wide range of projects. Shenzhou Tike Metal Co., Ltd. is a trusted manufacturer of perforated metal mesh, delivering quality products that meet the highest industry standards.

For more information about Perforated Metal Mesh and Shenzhou Tike Metal Co., Ltd., visit the company's product page or contact their team directly. Whether you're an engineer, architect, or manufacturer, Shenzhou Tike Metal offers the expertise and solutions to meet your needs.

RELATED PRODUCTS