Perforated metal mesh is a specialized material engineered to balance structural integrity with functional versatility. Its unique design allows for optimal airflow, light transmission, and customization, making it a preferred choice across diverse industries. This article explores the features, technical specifications, and applications of this advanced material, supported by insights from the National Institute of Standards and Technology (NIST).

The Sheet Plate Punching Mesh is engineered with precision to deliver exceptional performance. Below are its standout features:

Below is a detailed table of the Sheet Plate Punching Mesh specifications:

| Product Name | Perforated Metal Mesh |

|---|---|

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm–10mm |

| Opening Rate | 5%–80% |

| Aperture | 0.5mm–200mm |

| Hole Distance | 1mm–200mm |

| Size | 1m×2m, 1.22m×2.44m, 1.5m×3m, etc. |

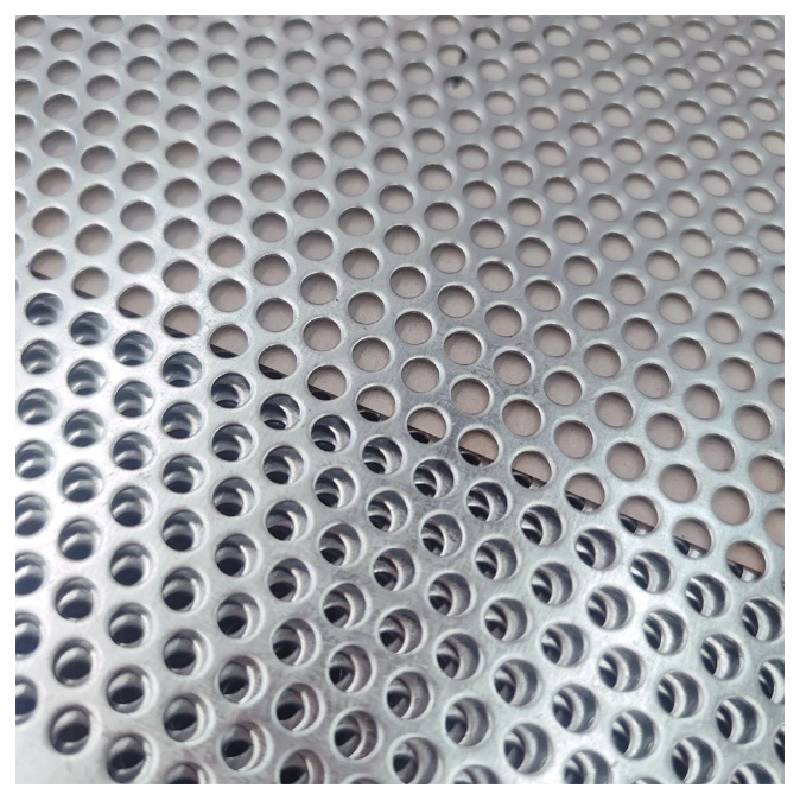

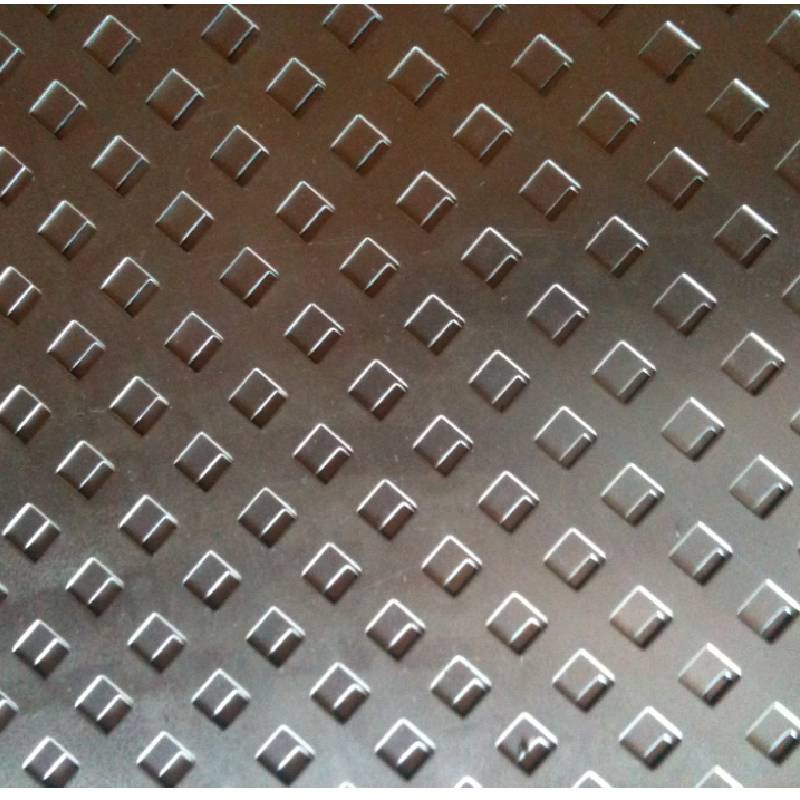

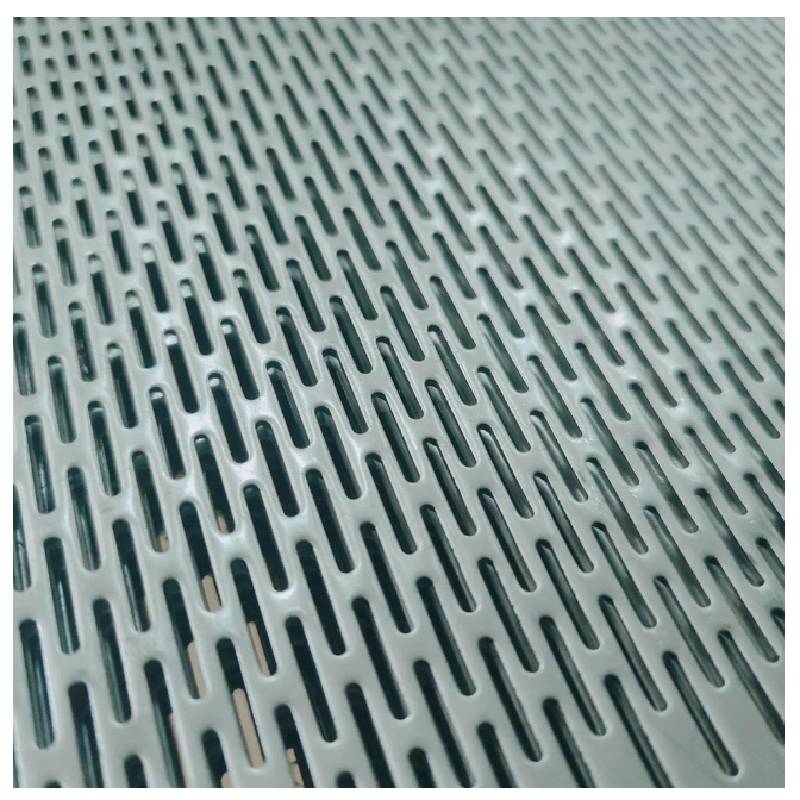

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150–200HB/30–50HB |

| Area Density | 20%–60% |

The Sheet Plate Punching Mesh is widely utilized in both industrial and architectural contexts. Key applications include:

As noted by NIST, "Precise material properties and standardized manufacturing processes are critical for ensuring reliability in industrial applications" (NIST). This aligns with the Sheet Plate Punching Mesh’s adherence to strict quality standards.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of metal products, specializing in Sheet Plate Punching Mesh and related solutions. With a commitment to innovation and sustainability, the company serves clients globally, offering high-quality materials tailored to diverse industrial needs. Their expertise in precision engineering ensures that each product meets rigorous performance criteria, as highlighted in NIST’s research on material standards (NIST).

Explore the Sheet Plate Punching Mesh in action through the following images:

The Sheet Plate Punching Mesh from Shenzhou Tike Metal Co., Ltd. exemplifies the fusion of innovation and practicality. Its advanced features, technical versatility, and environmental benefits make it a cornerstone of modern engineering. As NIST emphasizes, "Standardized material properties are essential for driving technological advancement" (NIST). This product stands as a testament to that principle, offering solutions that meet the evolving demands of industries worldwide.

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov

RELATED PRODUCTS