Perforated metal mesh has become a cornerstone in modern industrial and architectural applications due to its unique combination of durability, functionality, and aesthetic appeal. As a leading manufacturer, Shenzhou Tike Metal Co., Ltd. offers a wide range of perforated metal mesh products designed to meet the evolving needs of diverse industries. This article explores the features, advantages, technical specifications, application scenarios, and company background of perforated metal mesh, providing a comprehensive overview of its value and versatility.

Perforated metal mesh is engineered to deliver exceptional performance across a range of applications. Its high opening rate ensures optimal airflow and light transmission, making it ideal for ventilation and filtration systems. The lightweight design, achieved through its high opening rate, reduces material costs and facilitates easier handling and installation. Additionally, the corrosion resistance of perforated metal mesh ensures long-term durability, even in harsh environments.

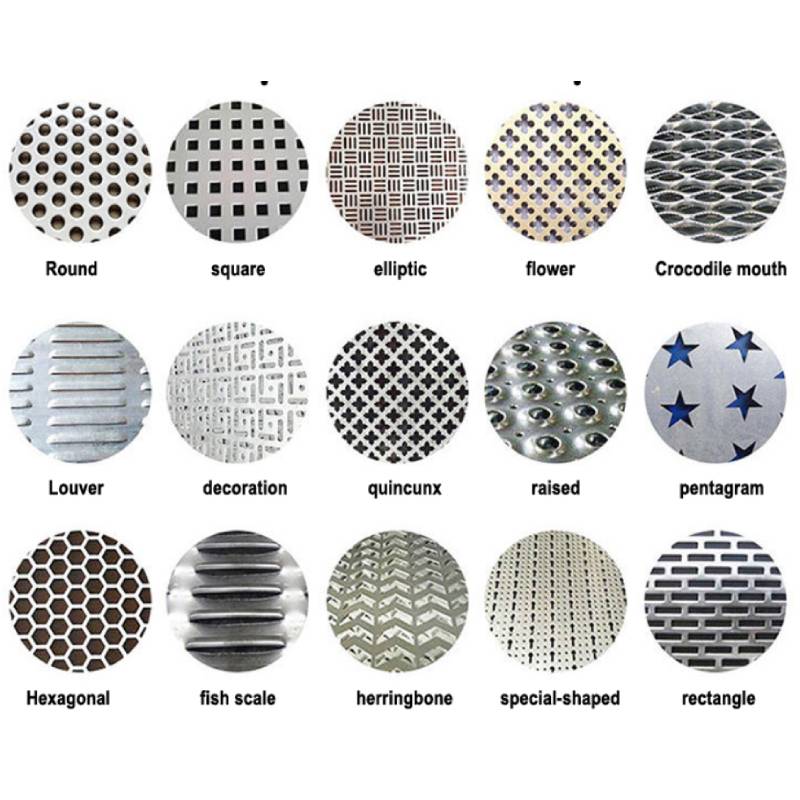

Customization is a hallmark of perforated metal mesh, allowing for the creation of beautiful patterns and shapes tailored to specific design requirements. The easy processing capabilities—enabling cutting, bending, and welding—further enhance its adaptability. Finally, the environmental protection aspect of perforated metal mesh makes it a sustainable choice, as it is fully recyclable and reusable.

The technical specifications of perforated metal mesh highlight its versatility and precision. Below is a detailed table outlining the key parameters:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm-10mm |

| Opening Rate | 5%-80% |

| Aperture | 0.5mm-200mm |

| Hole Distance | 1mm-200mm |

| Size | 1mx2m, 1.22mx2.44m, 1.5mx3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150-200HB/30-50HB |

| Area Density | 20%-60% |

The advantages of perforated metal mesh are manifold, making it a preferred choice in various industries. Its high opening rate ensures efficient air and light transmission, which is critical in applications such as HVAC systems and architectural facades. The lightweight design reduces structural load, making it ideal for large-scale installations. Furthermore, the corrosion resistance of perforated metal mesh ensures longevity, even in corrosive environments.

The customizable design allows for unique patterns and shapes, enabling architects and engineers to achieve both functional and aesthetic goals. The easy processing capabilities facilitate seamless integration into complex systems, while the environmental friendliness aligns with global sustainability initiatives. These advantages collectively position perforated metal mesh as a versatile and reliable material.

Perforated metal mesh finds extensive use in both industrial and architectural applications. In industrial settings, it is employed in oil filters, grain sifters, and sound isolation systems. Its ability to control airflow and filter particles makes it indispensable in manufacturing and processing environments. In architectural applications, perforated metal mesh is used for ventilation systems, acoustic panels, and decorative facades, enhancing both functionality and visual appeal.

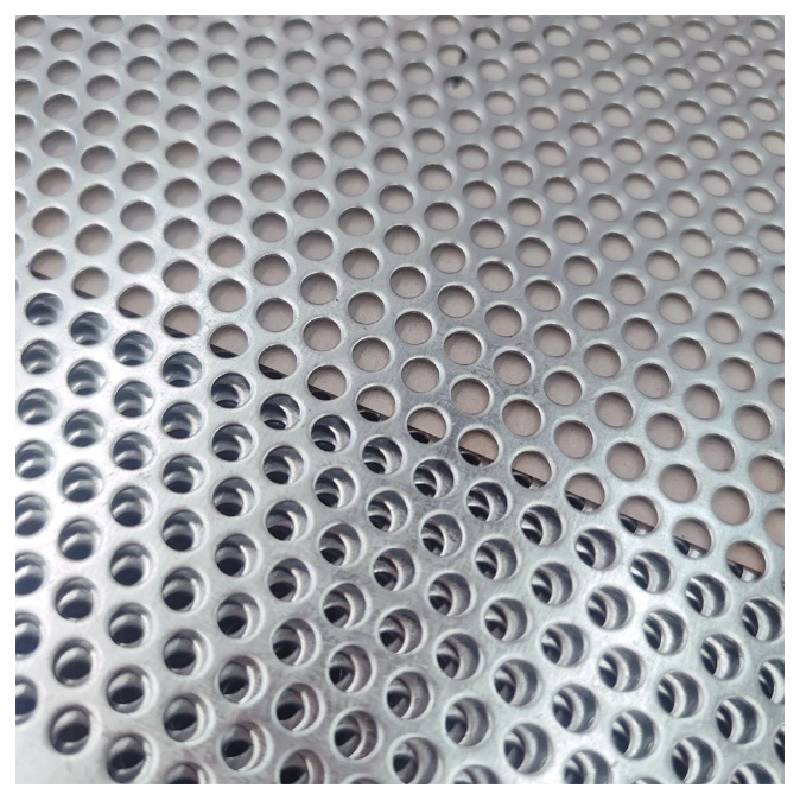

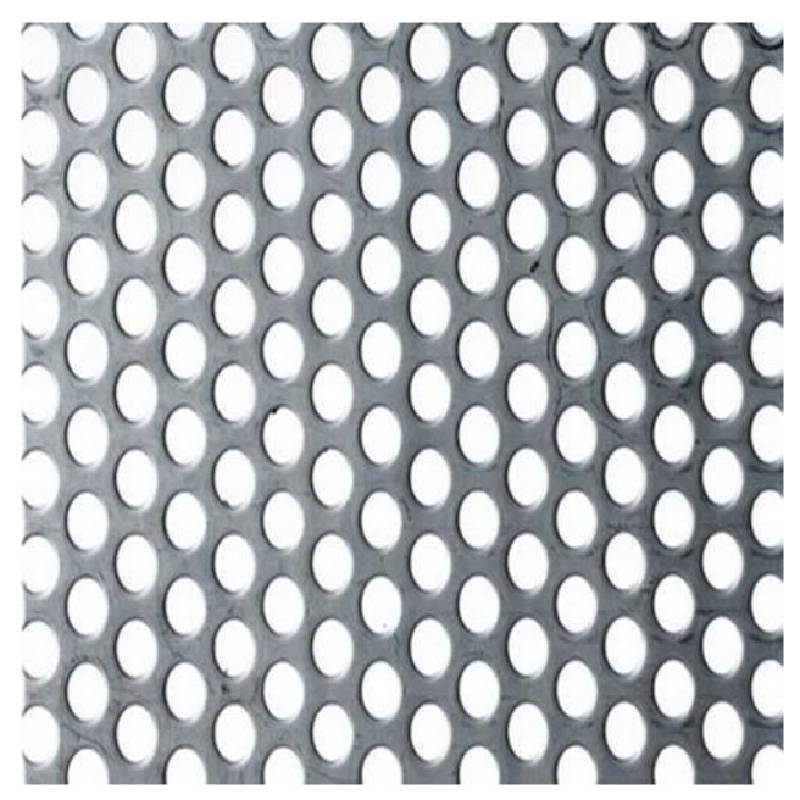

The round hole perforation is the most popular type, offering uniformity and consistency in performance. Other shapes, such as square and oval, provide additional design flexibility. The adaptability of perforated metal mesh ensures its relevance across a wide range of sectors, from construction to automotive and aerospace.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of perforated metal mesh, renowned for its commitment to quality, innovation, and customer satisfaction. With years of experience in the industry, the company has established itself as a trusted supplier of high-performance metal products. Their state-of-the-art facilities and advanced manufacturing technologies enable them to produce perforated metal mesh that meets the highest standards of precision and durability.

Shenzhou Tike Metal Co., Ltd. serves a global clientele, providing tailored solutions for diverse applications. Their product range includes sheet plate punching mesh, which is widely used in industrial and architectural projects. The company's dedication to sustainability is reflected in its eco-friendly manufacturing processes and recyclable materials, aligning with global environmental standards.

For more information about Shenzhou Tike Metal Co., Ltd., visit their official website.

The choice of perforated metal mesh is driven by its unique combination of properties that cater to both functional and aesthetic needs. Its high opening rate ensures optimal airflow and light transmission, making it ideal for ventilation and filtration systems. The lightweight design reduces material costs and facilitates easier handling, while the corrosion resistance guarantees long-term durability.

The customizable design allows for creative expression, enabling architects and engineers to achieve specific visual and functional goals. The easy processing capabilities ensure seamless integration into complex systems, while the environmental friendliness makes it a sustainable choice. These factors collectively make perforated metal mesh a versatile and reliable material for a wide range of applications.

The production of perforated metal mesh adheres to stringent industry standards to ensure quality and performance. While specific standards may vary by region and application, organizations like the National Institute of Standards and Technology (NIST) play a crucial role in establishing benchmarks for material properties and manufacturing processes. NIST's research and development efforts contribute to the advancement of measurement science, which is essential for maintaining consistency and reliability in industrial products.

For further information on industry standards related to perforated metal mesh, refer to the NIST website.

Perforated metal mesh is a versatile and high-performance material that offers a unique combination of durability, functionality, and aesthetic appeal. Its high opening rate, lightweight design, corrosion resistance, and customizable patterns make it an ideal choice for a wide range of industrial and architectural applications. Shenzhou Tike Metal Co., Ltd. continues to lead the industry with its commitment to innovation, quality, and sustainability, providing reliable solutions for global customers.

For more details about perforated metal mesh and other products, visit the product page or explore the company website.

RELATED PRODUCTS