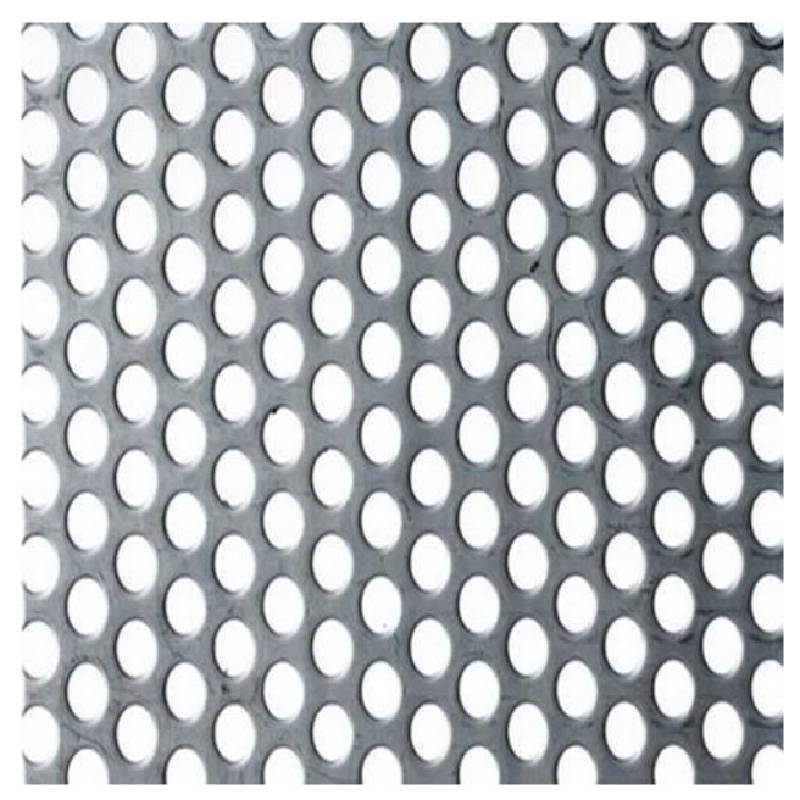

Perforated metal mesh has emerged as a critical component in modern industrial and architectural applications, offering a unique combination of durability, functionality, and aesthetic appeal. This article provides an in-depth exploration of the Perforated Metal Mesh, its technical specifications, and its diverse applications. Developed by Shenzhou Tike Metal Co., Ltd., this product exemplifies innovation in metal fabrication.

The Perforated Metal Mesh is designed to meet the demands of modern engineering and design. Its standout features include:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm – 10mm |

| Opening Rate | 5% – 80% |

| Aperture | 0.5mm – 200mm |

| Hole Distance | 1mm – 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

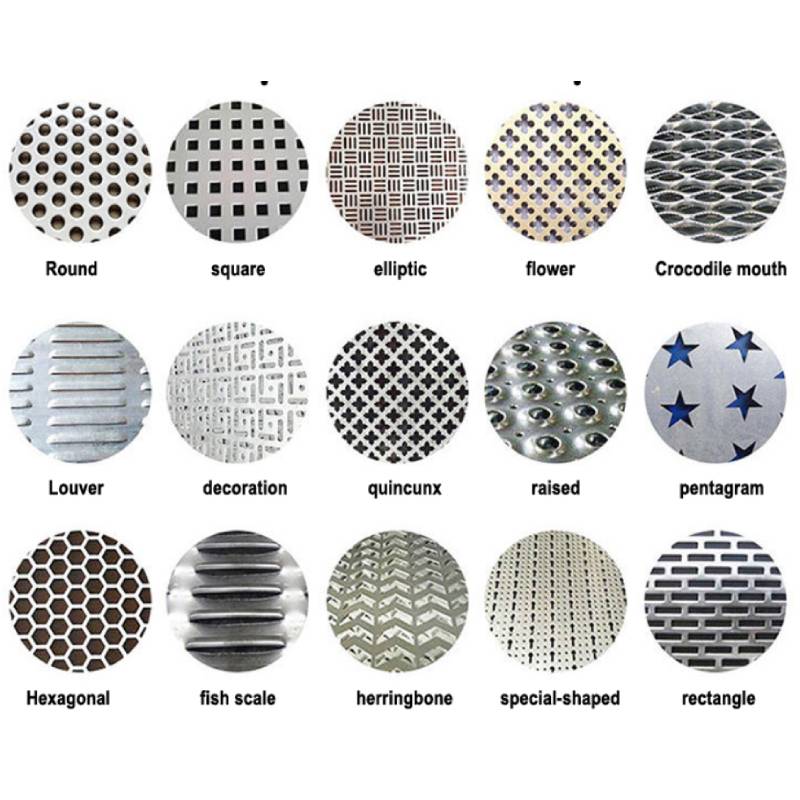

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% – 60% |

The Perforated Metal Mesh is widely used across industries due to its versatility. Key applications include:

Shenzhou Tike Metal Co., Ltd., a leading manufacturer of metal products, has established itself as a trusted name in the industry. With a focus on innovation and quality, the company provides solutions that meet global standards. Their commitment to Environmental Protection is evident in their sustainable practices, including the recyclability of their products. For more information, visit their official website.

The Perforated Metal Mesh by Shenzhou Tike Metal Co., Ltd. is a testament to the advancements in metal fabrication technology. Its combination of high performance, customization options, and environmental benefits makes it a preferred choice for a wide range of applications. As industries continue to prioritize sustainability and efficiency, products like this will play a crucial role in shaping the future of manufacturing and design.

National Institute of Standards and Technology (NIST) provides authoritative guidelines on material standards and testing procedures, ensuring the reliability and performance of industrial materials like perforated metal mesh.

RELATED PRODUCTS