Perforated metal mesh has become an essential component in a wide range of industrial and architectural applications due to its unique combination of functionality, durability, and aesthetic appeal. This article provides an in-depth exploration of the features, technical specifications, and applications of perforated metal mesh, along with insights into the company behind this innovative product.

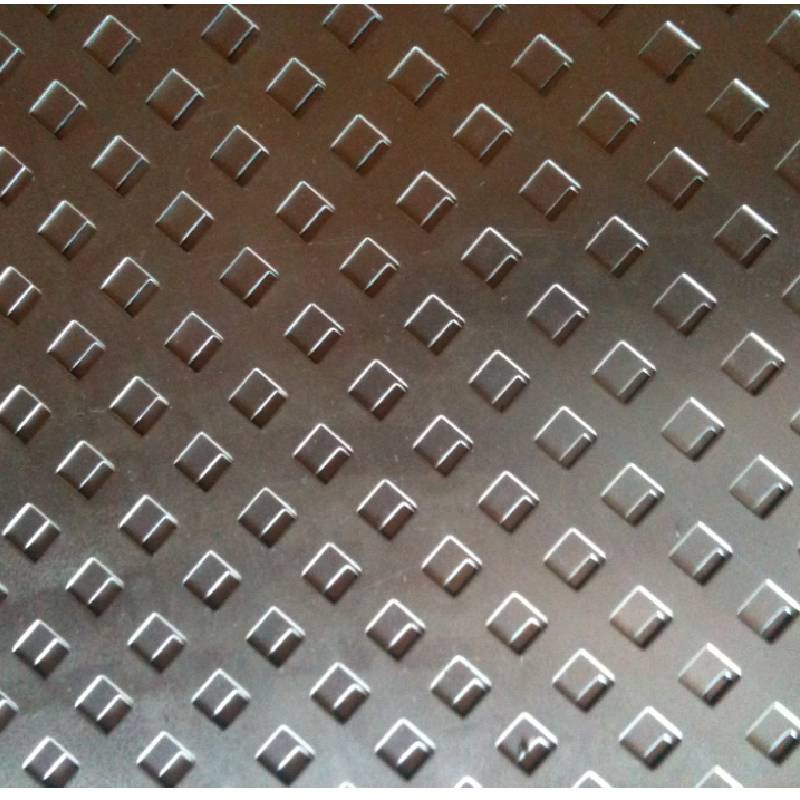

Sheet Plate Punching Mesh is a specialized form of metal mesh characterized by its high opening rate, lightweight design, and customizable patterns. Manufactured using advanced punching techniques, this product offers a balance between structural integrity and perforation efficiency. The product page provides detailed information on its capabilities and uses.

The Sheet Plate Punching Mesh is engineered to meet the demands of modern industrial and architectural projects. Its standout features include:

The following table outlines the detailed technical specifications of the Sheet Plate Punching Mesh:

| Parameter | Specification |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

The Sheet Plate Punching Mesh is widely used across multiple industries and architectural projects. Some of its key applications include:

The application images showcase the versatility of the mesh in real-world scenarios, including industrial filtration and architectural design.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of metal products, specializing in the production of Sheet Plate Punching Mesh. With decades of experience in the industry, the company has established itself as a reliable supplier of high-quality metal solutions for global markets.

As a company committed to innovation and sustainability, Shenzhou Tike Metal adheres to strict quality control standards and leverages advanced manufacturing technologies to ensure precision and consistency in its products. Their official website offers further details about their product range and services.

The production of Sheet Plate Punching Mesh aligns with international standards for material performance and safety. According to the National Institute of Standards and Technology (NIST), precise measurements and standardized testing are critical for ensuring the reliability of industrial materials. While specific NIST certifications for this product are not detailed in the context, the principles of measurement accuracy and quality assurance emphasized by NIST are integral to the manufacturing process.

As noted by NIST, "Without precise measurements, your car wouldn’t run, your phone wouldn’t work, and hospitals couldn’t function." This underscores the importance of adhering to rigorous standards in the production of materials like perforated metal mesh.

The Sheet Plate Punching Mesh exemplifies the perfect blend of functionality, durability, and aesthetics. Its high opening rate, lightweight design, and customizable features make it an ideal choice for diverse applications. As a trusted manufacturer, Shenzhou Tike Metal Co., Ltd. continues to drive innovation in the metal industry, delivering products that meet the evolving needs of global markets.

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov

RELATED PRODUCTS