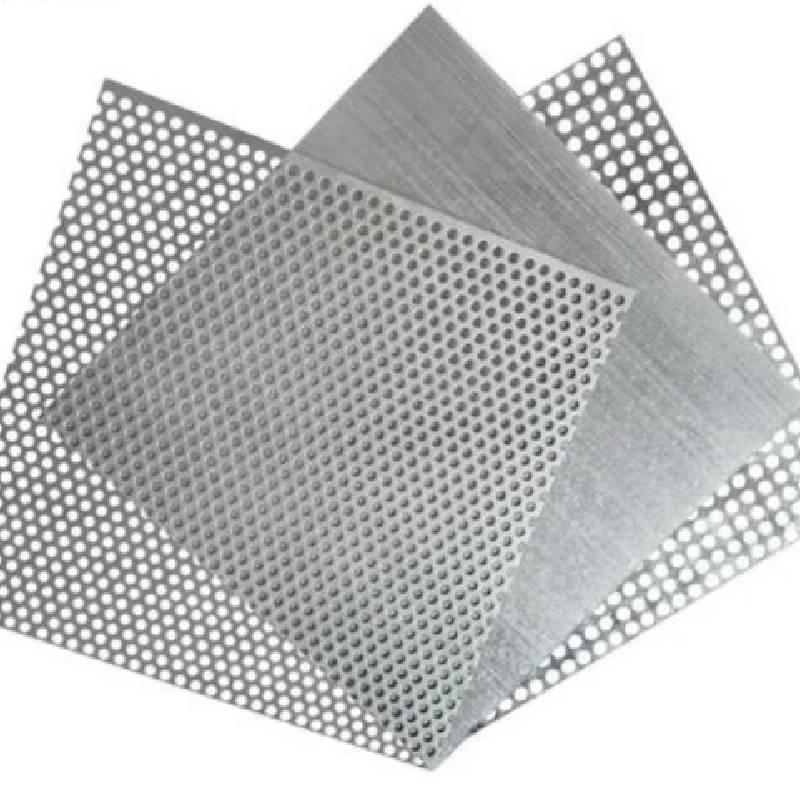

Perforated metal mesh is a highly versatile material that combines functionality, durability, and aesthetic appeal. With its unique design and customizable features, it has become a staple in various industries, from manufacturing to construction. This article delves into the core features, technical specifications, applications, and the company behind this innovative product, Perforated Metal Mesh.

Perforated metal mesh is engineered to meet the demands of modern industrial and architectural applications. Its standout features include:

The opening rate of perforated metal mesh can exceed 30%, ensuring excellent air permeability and light transmission. This makes it ideal for applications requiring ventilation, filtration, or acoustic control. The high opening rate also contributes to the material's lightweight nature, reducing the overall weight of the final product without compromising structural integrity.

Due to its high opening rate, perforated metal mesh is significantly lighter than solid metal sheets of the same size. This characteristic makes it easier to handle, transport, and install, reducing labor costs and improving efficiency in large-scale projects.

Perforated metal mesh can be manufactured from a variety of materials, including stainless steel, aluminum, and galvanized steel, each offering excellent corrosion resistance. This makes it suitable for use in harsh environments, such as coastal regions or industrial facilities where exposure to moisture and chemicals is common.

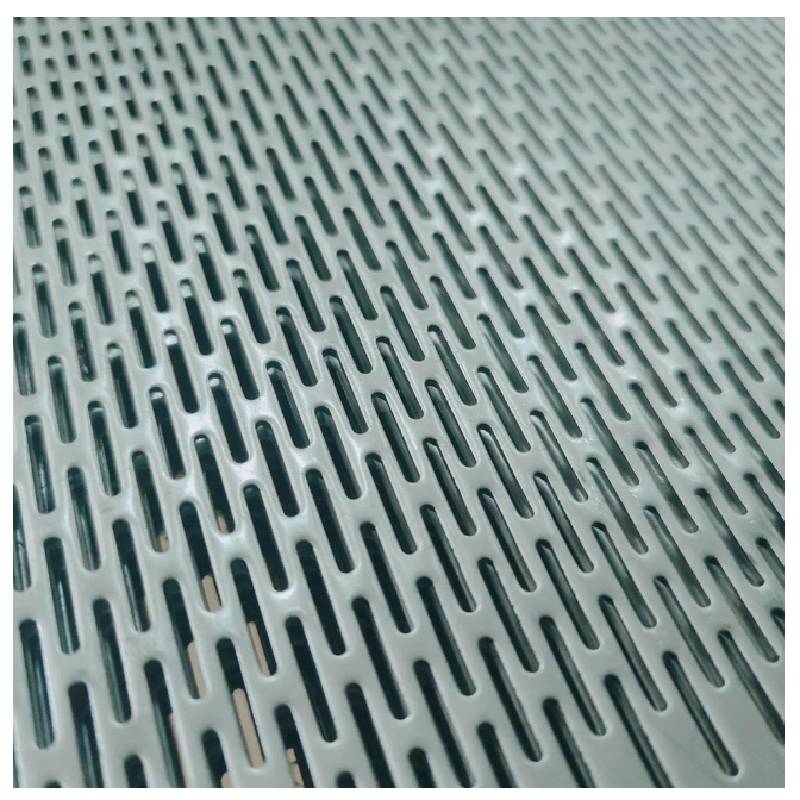

One of the most appealing aspects of perforated metal mesh is its ability to be customized. The opening shapes, patterns, and finishes can be tailored to meet specific design requirements. This flexibility allows the material to blend seamlessly into architectural elements while maintaining its functional properties.

Perforated metal mesh is highly versatile in terms of processing. It can be cut, bent, welded, and shaped to fit specific project needs. This adaptability ensures that the material can be integrated into a wide range of applications, from simple filters to complex structural components.

Perforated metal mesh is 100% recyclable, making it an environmentally sustainable choice. Its reusability reduces waste and supports green building practices, aligning with global efforts to minimize the environmental impact of industrial materials.

The following table outlines the key technical specifications of Perforated Metal Mesh:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

Perforated metal mesh is widely used across multiple industries due to its versatility and performance. Some of the key applications include:

Perforated metal mesh is commonly employed in industrial settings for filtration, screening, and separation processes. For example:

In the construction industry, perforated metal mesh is used for both functional and aesthetic purposes:

Perforated metal mesh also finds applications in:

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of perforated metal products, dedicated to providing high-quality solutions for industrial and architectural applications. With years of experience in the industry, the company has established a reputation for innovation, precision, and customer satisfaction. Their commitment to quality is reflected in the advanced manufacturing processes and rigorous testing of their products.

As a trusted name in the metal processing industry, Shenzhou Tike Metal Co., Ltd. continues to invest in research and development to meet the evolving needs of its clients. Their products are designed to meet international standards, ensuring reliability and performance in diverse environments.

Perforated metal mesh is a multifunctional material that combines strength, durability, and aesthetic appeal. Its high opening rate, lightweight design, corrosion resistance, and customizable features make it an ideal choice for a wide range of applications. Whether used in industrial filtration systems, architectural designs, or consumer products, this material continues to drive innovation and efficiency.

For more information about Perforated Metal Mesh and the services offered by Shenzhou Tike Metal Co., Ltd., visit their official website. The company's commitment to quality and sustainability ensures that their products meet the highest standards, making them a reliable partner for businesses and architects worldwide.

As noted by the National Institute of Standards and Technology (NIST), "measurements and research fuel innovation and improve the quality of life for all Americans" [1]. The development of advanced materials like perforated metal mesh exemplifies how precision engineering and scientific research contribute to technological progress.

RELATED PRODUCTS