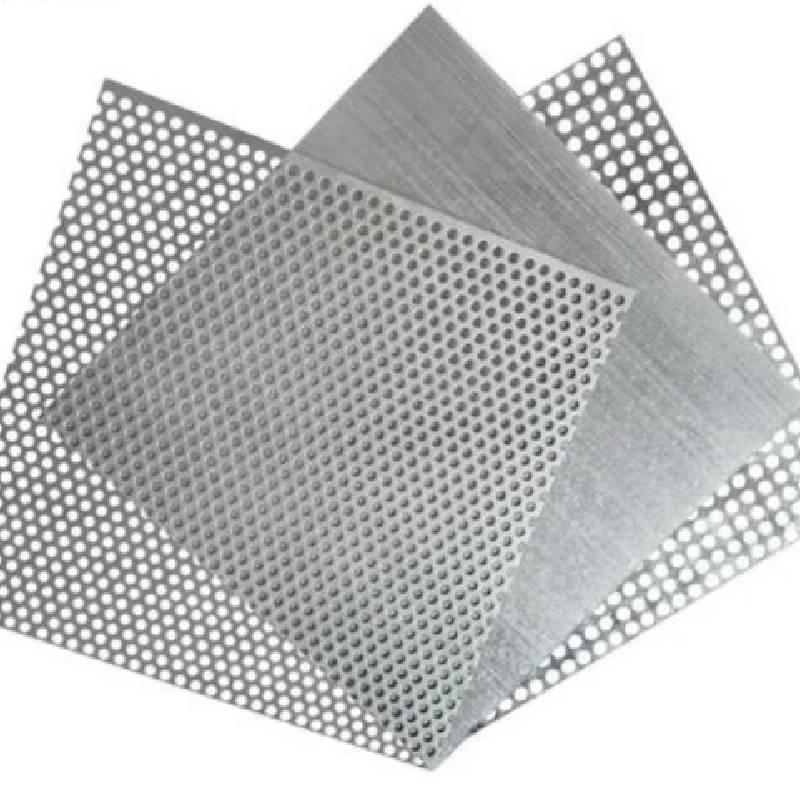

Perforated metal mesh is a highly adaptable material that combines structural integrity with functional versatility. Its unique design allows for optimal airflow, light transmission, and customization, making it a preferred choice across various industries. This article delves into the Perforated Metal Mesh product, exploring its features, technical specifications, applications, and the company behind it. Whether you're an engineer, architect, or industry professional, this comprehensive guide will help you understand the value and potential of this innovative material.

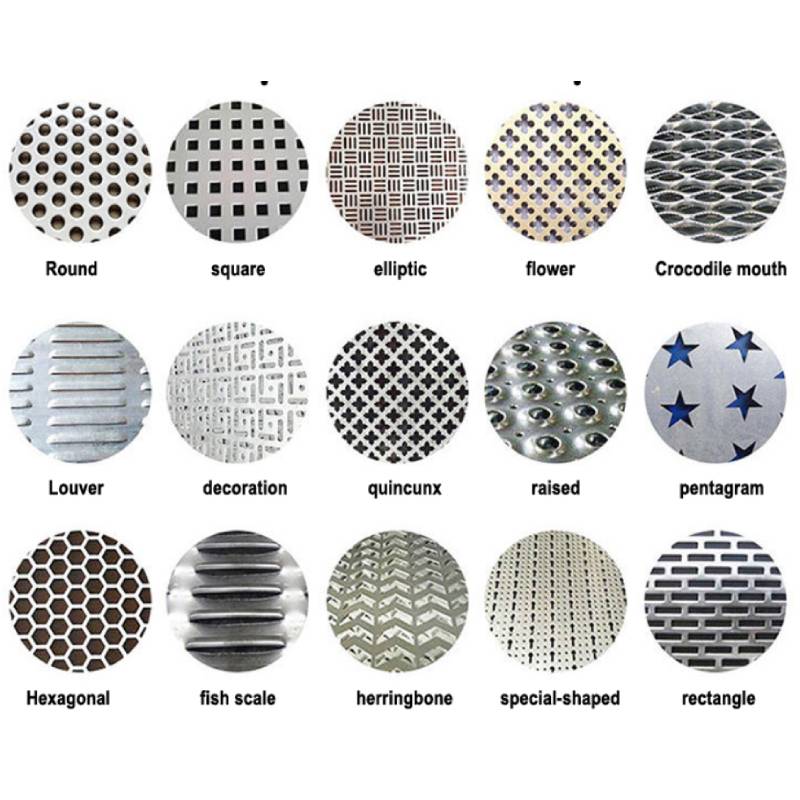

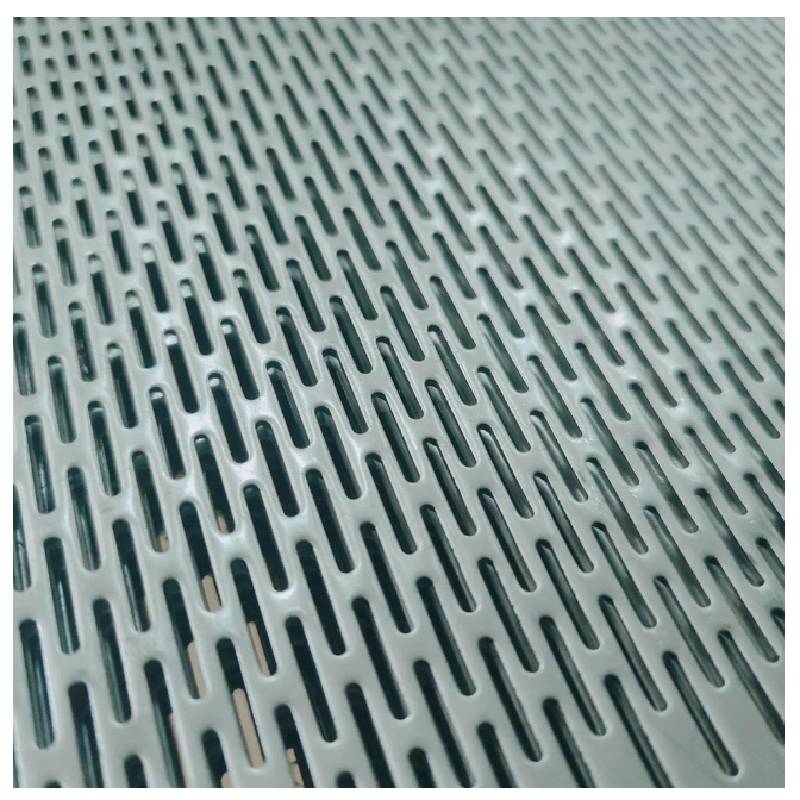

The Perforated Metal Mesh is engineered to meet diverse industrial and architectural demands. Its standout features include:

The Perforated Metal Mesh is available in a wide range of configurations to suit different applications. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm – 10mm |

| Opening Rate | 5% – 80% |

| Aperture | 0.5mm – 200mm |

| Hole Distance | 1mm – 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa – 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% – 60% |

The Perforated Metal Mesh offers several advantages that make it a superior choice over traditional materials:

According to NIST standards, perforated materials are often evaluated for their structural integrity and performance under varying conditions. The Perforated Metal Mesh aligns with these benchmarks, ensuring reliability and compliance with industry regulations.

The Perforated Metal Mesh is widely used in both industrial and architectural settings. Some of its key applications include:

For example, the Perforated Metal Mesh is commonly used in the construction of Sheet Plate Punching Mesh for industrial enclosures, where its corrosion resistance and lightweight properties are critical.

Shenzhou Tike Metal Co., Ltd. (SHENZHOU TIKE METAL CO., LTD.) is a leading manufacturer of Perforated Metal Mesh and related products. With years of experience in the metalworking industry, the company has established itself as a trusted supplier of high-quality perforated materials. Their commitment to innovation, precision, and customer satisfaction ensures that their products meet the highest standards of performance and reliability.

Shenzhou Tike Metal Co., Ltd. is dedicated to providing tailored solutions for clients across various sectors. Their expertise in Sheet Plate Punching Mesh and other metal products has earned them a reputation for excellence in the global market. For more information about the company, visit their official website.

The Perforated Metal Mesh from Shenzhou Tike Metal Co., Ltd. is a versatile, durable, and sustainable solution for a wide range of applications. Its combination of high performance, customization options, and environmental benefits makes it an essential material for modern industries and architectural projects. Whether you're looking for efficient ventilation systems, sound insulation, or decorative elements, this product offers a reliable and cost-effective option.

NIST (National Institute of Standards and Technology) provides authoritative guidelines and standards for materials and manufacturing processes. For more information on material performance and testing, visit https://www.nist.gov/.

RELATED PRODUCTS