Perforated metal mesh has become an essential component in modern industrial and architectural solutions due to its versatility, durability, and customizable design. As a leading manufacturer in the metal processing industry, SHENZHOU TIKE METAL CO., LTD. offers high-quality perforated metal mesh that meets the demands of diverse applications. This article provides an in-depth analysis of the product's features, technical specifications, and real-world applications, supported by authoritative references and industry insights.

High Opening Rate: One of the most significant advantages of perforated metal mesh is its high opening rate, which can exceed 30%. This design allows for excellent air permeability and light transmission, making it ideal for applications requiring ventilation or natural lighting. According to NIST (National Institute of Standards and Technology), materials with high porosity often exhibit enhanced functional performance in environmental control systems.

Lightweight Design: Due to its high opening rate, perforated metal mesh is significantly lighter than solid metal sheets of the same size. This characteristic reduces material costs and simplifies installation processes, particularly in large-scale architectural projects.

Corrosion Resistance: The material can be fabricated from various metal plates, including stainless steel, aluminum, and galvanized steel, which provide excellent corrosion resistance. This makes the product suitable for harsh environments, such as marine or chemical processing facilities.

Customizable Aesthetics: The perforation patterns can be tailored to meet specific design requirements. Whether it's geometric shapes, floral motifs, or abstract designs, the product offers a wide range of aesthetic possibilities. As noted in NIST's research on material aesthetics, visual appeal is a critical factor in architectural applications.

Easy Processability: Perforated metal mesh is highly malleable, allowing for cutting, bending, welding, and other processing techniques. This flexibility ensures compatibility with various manufacturing workflows.

Environmental Sustainability: The product is fully recyclable, aligning with global trends toward eco-friendly materials. This feature supports sustainable development goals and reduces the environmental footprint of industrial projects.

| Parameter | Specification |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

Perforated metal mesh is widely used in both industrial and architectural applications. Its adaptability makes it a preferred choice for:

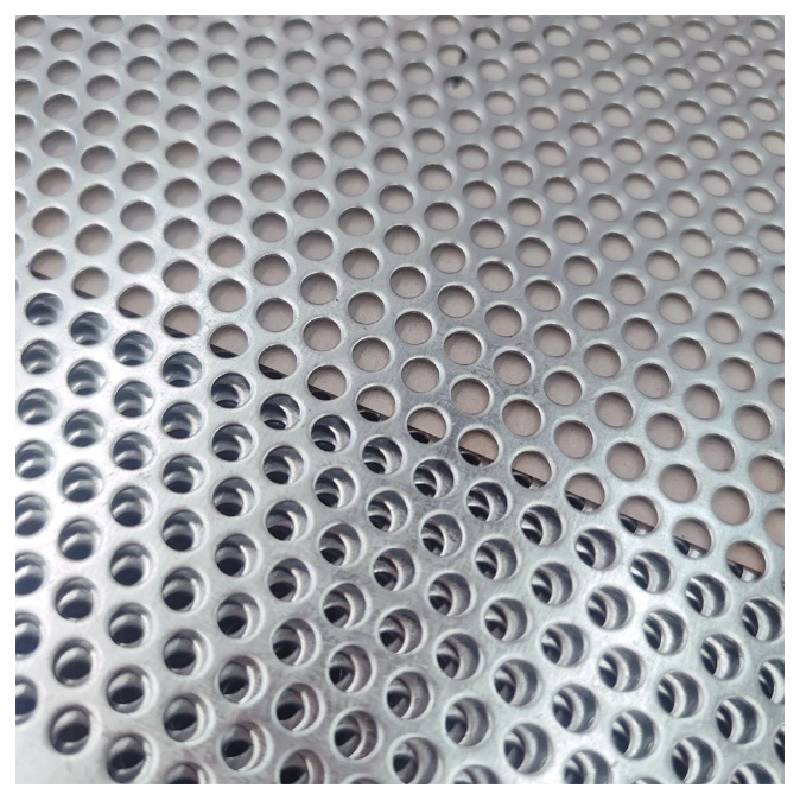

For example, the round hole perforation is the most popular pattern due to its balance between structural strength and aesthetic appeal.

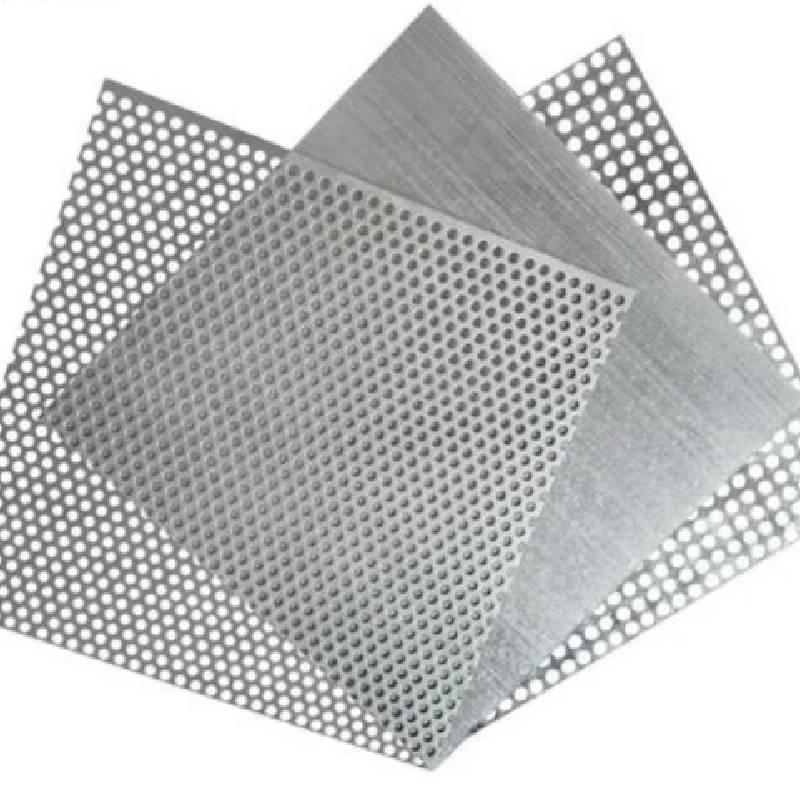

Below are visual representations of the product's versatility:

As a trusted manufacturer in the metal processing industry, SHENZHOU TIKE METAL CO., LTD. specializes in producing high-quality perforated metal mesh tailored to client needs. With a commitment to innovation and sustainability, the company ensures that its products meet international standards and environmental regulations.

Perforated metal mesh combines functionality, durability, and aesthetic appeal, making it an indispensable material in modern engineering and design. By leveraging advanced manufacturing techniques and adhering to strict quality control, SHENZHOU TIKE METAL CO., LTD. continues to lead the industry in providing solutions that meet the evolving demands of global markets.

NIST (National Institute of Standards and Technology) - Research on material properties and environmental impact.

SHENZHOU TIKE METAL CO., LTD. - Product specifications and company information.

RELATED PRODUCTS