Perforated metal mesh has become an essential material in modern industrial and architectural applications due to its unique combination of functionality, durability, and aesthetic appeal. As a leading supplier, Shenzhou Tike Metal Co., Ltd. offers high-quality perforated metal mesh that meets the diverse needs of global industries. This article provides an in-depth analysis of the product's features, technical specifications, applications, and the company's commitment to innovation.

Perforated metal mesh is engineered to deliver exceptional performance across multiple dimensions. Its design allows for a high opening rate, typically exceeding 30%, which ensures excellent air permeability and light transmission. This makes it ideal for applications requiring ventilation, filtration, or acoustic control. The lightweight nature of the mesh, achieved through its high opening rate, reduces material costs and facilitates easier handling and installation compared to solid metal sheets of the same size.

Corrosion resistance is another critical advantage of perforated metal mesh. The material can be manufactured from various metals, including stainless steel, aluminum, and galvanized steel, each offering tailored resistance to environmental factors. This versatility ensures the mesh can withstand harsh conditions in industrial environments or outdoor settings. Additionally, the customizable design allows for the creation of unique patterns and shapes, enhancing both functionality and visual appeal.

Easy processing is a hallmark of perforated metal mesh. It can be cut, bent, welded, and formed into complex shapes without compromising structural integrity. This flexibility makes it suitable for a wide range of applications, from simple grating systems to intricate architectural elements. Furthermore, the material's recyclability aligns with modern sustainability goals, as it can be reused or repurposed without significant loss of quality.

The technical specifications of perforated metal mesh are designed to meet the exacting demands of various industries. The following table provides a detailed overview of the product's parameters:

| Parameter | Specification |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150-200HB/30-50HB |

| Area Density | 20% - 60% |

The product's customization options are extensive. Users can specify the type of metal, hole size, and pattern to suit their specific requirements. For example, round holes are the most popular choice due to their uniformity and ease of manufacturing, while square or oval holes offer alternative aesthetic and functional benefits. The mesh's tensile strength and hardness ensure it can withstand mechanical stress, making it suitable for demanding applications.

Perforated metal mesh finds widespread use in both industrial and architectural contexts. One of its primary applications is in NIST-compliant filtration systems, where its high opening rate and durability make it ideal for oil filters, grain sifters, and air purification units. The mesh's ability to allow airflow while retaining particulate matter is critical in these scenarios.

In architectural design, perforated metal mesh is used for sound insulation, ventilation, and decorative elements. Its acoustic properties help reduce noise pollution in buildings, while its open structure allows for natural ventilation. The material's aesthetic versatility enables it to be integrated into modern facades, ceilings, and partitions, adding both functionality and visual interest.

Other applications include industrial grating for walkways and platforms, where its lightweight and corrosion-resistant properties ensure safety and longevity. In the automotive and aerospace sectors, the mesh is used for heat dissipation and component shielding. Its recyclability further enhances its appeal in industries prioritizing sustainability.

Shenzhou Tike Metal Co., Ltd. is a reputable manufacturer of metal products, specializing in perforated metal mesh and related solutions. With a focus on innovation and quality, the company has established itself as a trusted supplier to clients worldwide. Its commitment to precision engineering and customer-centric approaches ensures that products meet the highest standards of performance and reliability.

The company's facilities are equipped with advanced machinery and skilled technicians, enabling the production of custom-designed perforated metal mesh. By leveraging cutting-edge technology and adhering to international quality certifications, Shenzhou Tike Metal Co., Ltd. delivers products that exceed industry expectations. For more information about their services, visit their official website.

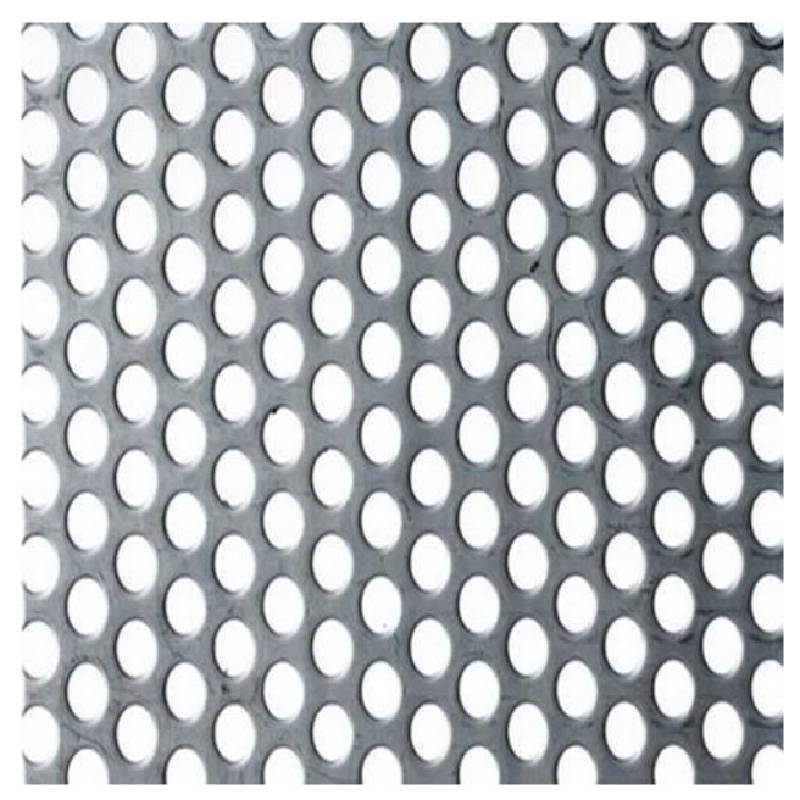

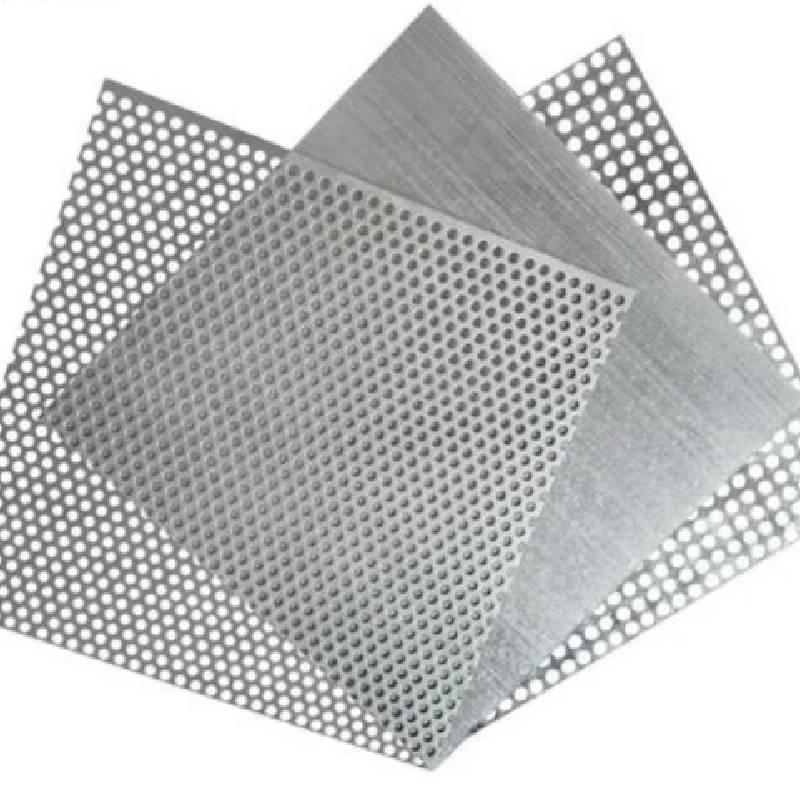

Below are images of the product, highlighting its diverse applications and design flexibility:

Perforated metal mesh is a versatile and durable material that plays a vital role in modern industrial and architectural solutions. Its unique combination of high opening rate, lightweight design, corrosion resistance, and customization options makes it an ideal choice for a wide range of applications. Shenzhou Tike Metal Co., Ltd. continues to lead the industry by delivering high-quality products that meet the evolving needs of global markets.

For further details about the product, visit the Perforated Metal Mesh page or explore the company's official website.

National Institute of Standards and Technology (NIST) - Technical standards and guidelines for metal materials.

RELATED PRODUCTS