In today's rapidly evolving industrial and architectural landscapes, Perforated Metal Mesh has emerged as a versatile solution that combines functionality with aesthetic appeal. This article delves into the core features, technical specifications, and applications of this innovative material, while also exploring the company behind it. Whether you're an engineer, architect, or industry professional, this guide will provide valuable insights into the capabilities of perforated metal mesh.

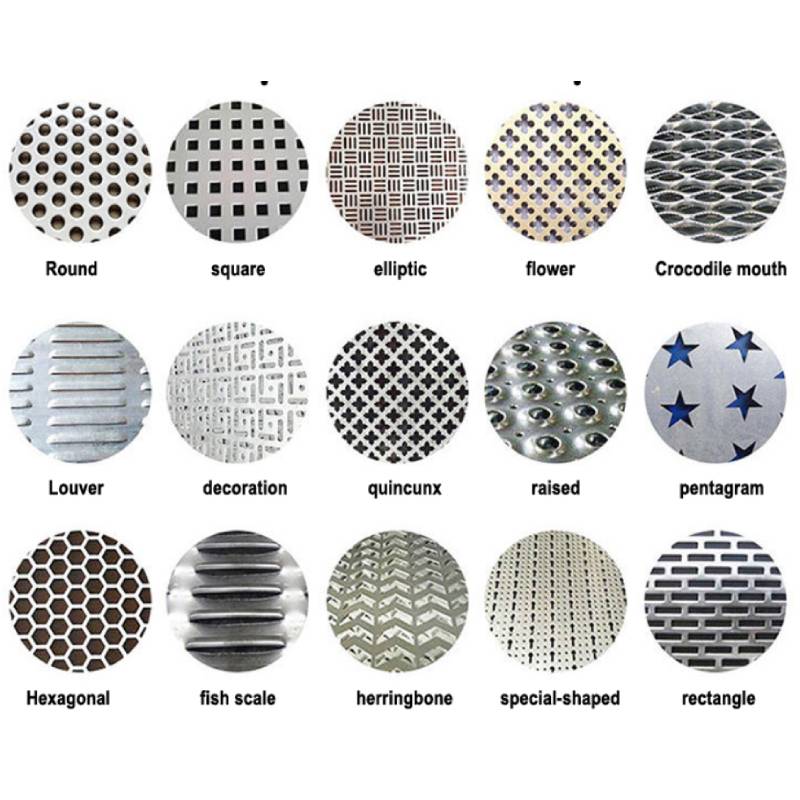

Perforated metal mesh is renowned for its unique combination of properties that make it suitable for a wide range of applications. Let's explore its most notable features:

The following table provides a detailed overview of the technical parameters of the perforated metal mesh:

| Parameter | Specification |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

Perforated metal mesh is widely used across various industries due to its adaptability and performance. Some of the key applications include:

Founded in 2010, Shenzhen Tike Metal Co., Ltd. has established itself as a leading manufacturer of metal mesh products. Located in Shenzhou City, the company specializes in producing high-quality perforated metal mesh that meets international standards. With a commitment to innovation and customer satisfaction, Shenzhen Tike Metal has earned a reputation for delivering reliable solutions to clients worldwide.

As a pioneer in the metal mesh industry, the company invests heavily in research and development to stay ahead of technological advancements. Their state-of-the-art production facilities ensure precision and consistency in every product. Shenzhen Tike Metal's dedication to quality is reflected in their compliance with global standards, including those set by the National Institute of Standards and Technology (NIST), which plays a crucial role in defining material performance criteria.

The use of perforated metal mesh offers significant environmental and economic advantages. Its recyclability reduces waste and supports sustainable manufacturing practices. Additionally, the lightweight nature of the mesh lowers transportation costs and energy consumption during installation. For businesses, these benefits translate into cost savings and a reduced environmental footprint, making perforated metal mesh a smart choice for forward-thinking projects.

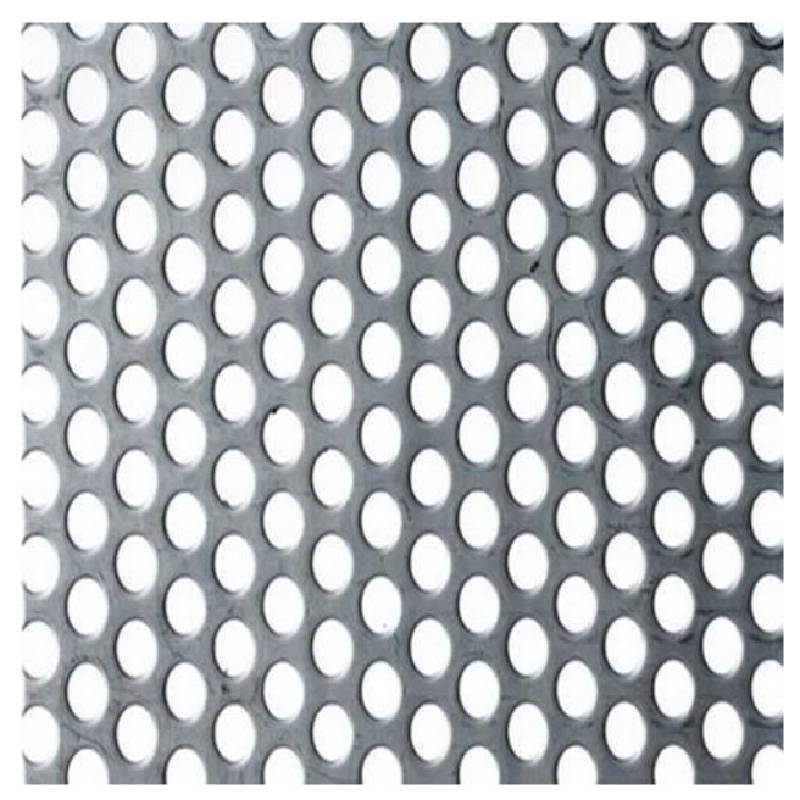

Below are some examples of the perforated metal mesh produced by Shenzhen Tike Metal:

New Project (7)

New Project (1)

New Project (6)

Perforated metal mesh is a versatile and durable material that offers numerous benefits across various industries. Its high opening rate, lightweight design, and customizable patterns make it an ideal choice for both functional and aesthetic applications. With the expertise of Shenzhen Tike Metal Co., Ltd., this product continues to set benchmarks in the metal mesh industry. As technology advances, the potential applications of perforated metal mesh are expected to expand, further solidifying its role in modern engineering and design.

[1] National Institute of Standards and Technology (NIST). (n.d.). https://www.nist.gov/

RELATED PRODUCTS