Perforated metal mesh has emerged as a critical component in modern industrial and architectural applications, offering a unique combination of structural integrity, functional versatility, and aesthetic appeal. This article explores the Perforated Metal Mesh product, its technical specifications, and its role in advancing engineering solutions. By leveraging insights from the National Institute of Standards and Technology (NIST), we will examine how this material aligns with industry standards and innovation benchmarks.

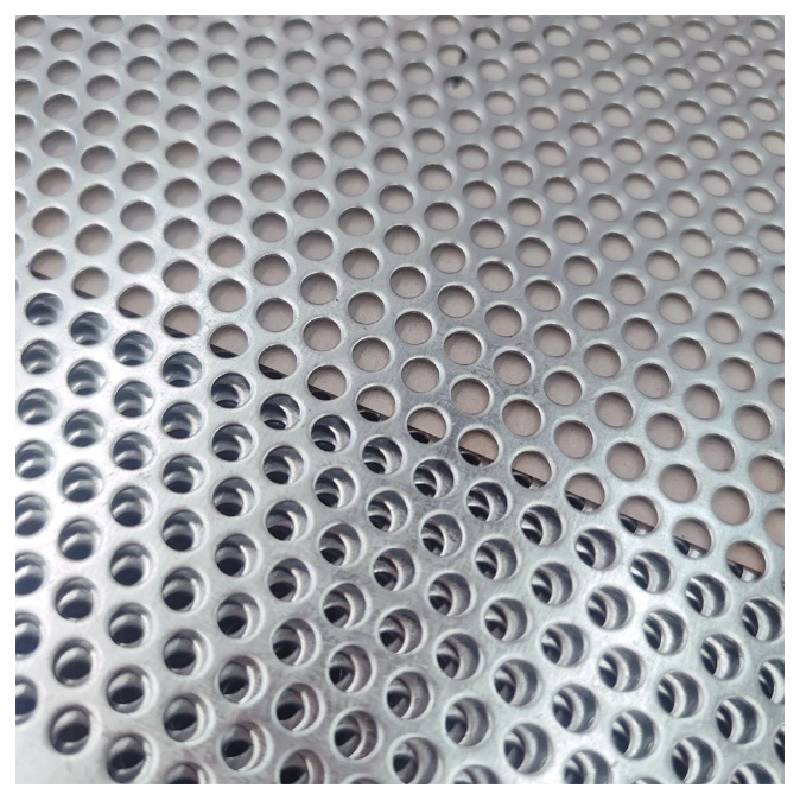

The Perforated Metal Mesh is a specialized material designed to balance durability, functionality, and adaptability. Manufactured through precision punching techniques, this mesh features a high opening rate, lightweight construction, and customizable design options. Its applications span across industries, from filtration systems to architectural facades, making it a cornerstone of modern engineering.

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm–10mm |

| Opening Rate | 5%–80% |

| Aperture | 0.5mm–200mm |

| Hole Distance | 1mm–200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150–200HB/30–50HB |

| Area Density | 20%–60% |

The Perforated Metal Mesh is a versatile solution for a wide range of applications. Its adaptability and performance characteristics make it a preferred choice in the following domains:

Founded as a leader in metal mesh innovation, Shenzhen Tike Metal Co., Ltd. specializes in producing high-quality perforated metal products. With a focus on precision engineering and customer-centric solutions, the company has established itself as a trusted supplier in global markets. Their commitment to sustainability and technological advancement aligns with industry standards, ensuring products meet rigorous quality and performance benchmarks.

As highlighted by the National Institute of Standards and Technology (NIST), "Precision in material engineering is critical for ensuring the reliability and efficiency of industrial components." Shenzhen Tike Metal Co., Ltd. adheres to these principles, leveraging advanced manufacturing techniques to deliver products that meet and exceed industry expectations.

Custom-designed perforated mesh for architectural applications

Industrial-grade perforated mesh for filtration systems

Lightweight structural component for modular construction

According to NIST, "Standardization of materials and processes is essential for ensuring interoperability and safety in industrial applications." The Perforated Metal Mesh adheres to these principles, with its technical specifications reflecting industry best practices. For instance, the material's tensile strength and hardness values align with standards for structural components, while its opening rate and aperture dimensions meet requirements for filtration and ventilation systems.

Furthermore, the mesh's environmental sustainability is a key factor in its appeal. As NIST emphasizes, "Sustainable manufacturing practices are critical for reducing the ecological footprint of industrial materials." The recyclability of the Perforated Metal Mesh supports this goal, offering a green alternative to traditional materials.

The Perforated Metal Mesh represents a convergence of innovation, functionality, and sustainability. Its technical specifications, combined with its adaptability to diverse applications, make it a valuable asset in both industrial and architectural contexts. By aligning with NIST's standards for precision and sustainability, Shenzhen Tike Metal Co., Ltd. continues to set benchmarks for quality and reliability in the metal mesh industry.

NIST (National Institute of Standards and Technology): https://www.nist.gov/

Shenzhen Tike Metal Co., Ltd.: https://www.tikemetal.com

Perforated Metal Mesh Product Page: https://www.tikemetal.com/perforated-metal-mesh.html

RELATED PRODUCTS