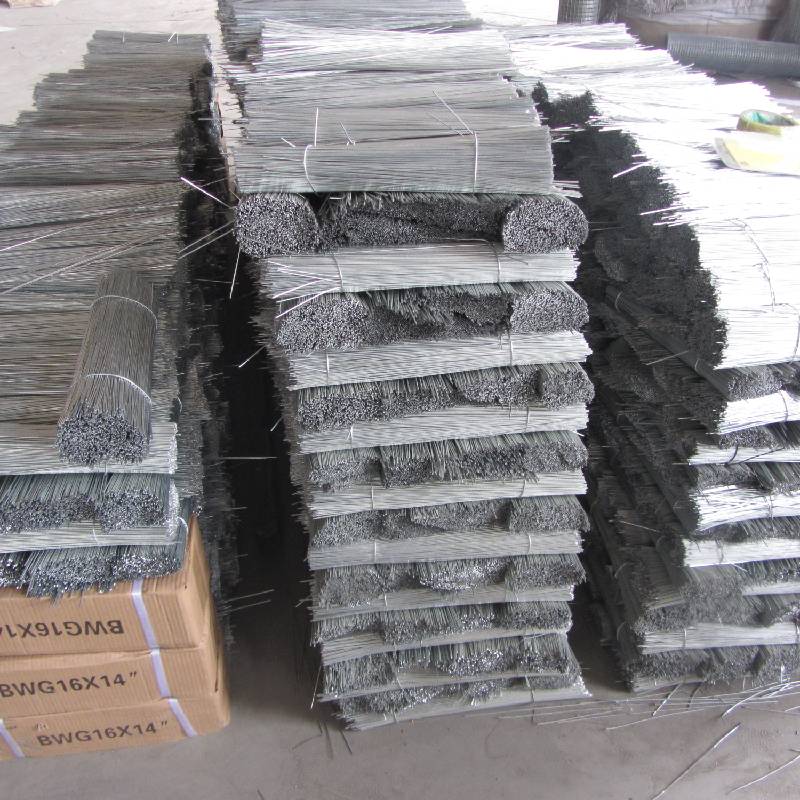

If you work with foam cutters, food portioners, lab rigs, or just rugged shop fixtures, you already know how fussy a good Cutting Wire can be. The right wire keeps lines clean, loads predictable, and downtime low. I’ve toured the workshops in Hebei—origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City—and, to be honest, the best plants there now run tighter process control than some European outfits I’ve seen.

Three real shifts: tighter diameter tolerances for automated gantries, coatings that survive humid shops, and traceability (QR-coded spools). Actually, buyers keep asking for mixed-material batches—stainless for food contact, nichrome for hot-wire foam cutting, and high-carbon steel for general fixtures—shipped together to cut freight. It seems that speed of customization beats rock-bottom price now.

Typical materials: 304/316L stainless (food, corrosion resistance), high-carbon steel (ASTM/EN spring grades), and nichrome (hot-wire cutting). Coatings: bright, zinc, tin, or polymer. In fact, the team markets it as easy to transport and use—spool handling is straightforward.

| Parameter | Spec (real-world ≈) |

|---|---|

| Diameter range | 0.10–1.00 mm (±0.005–0.01 mm) |

| Tensile strength | 1500–2800 MPa (grade-dependent) |

| Elongation | 2–12% (per ASTM A313 / EN 10270-1) |

| Spool length | ≈0.5–5 km/spool (by diameter) |

| Coating | Bright, Zn, Sn, polymer (optional) |

Materials → multi-stage drawing → stress relieving → surface prep → coating (as needed) → precision spooling → QC. Testing includes diameter via laser mic, tensile/elongation per ISO 6892-1, torsion, and 72–168 h salt spray for coated types. Service life: in reciprocating rigs, high-carbon Cutting Wire clocked >50,000 cycles at ≈60% UTS; stainless varies with load and environment.

| Vendor | Tensile consistency | MOQ | Lead time | Customization | Certs |

|---|---|---|---|---|---|

| Tikemetal (Cutting Wire) | ±3–5% UTS, stable | Low (around 200–300 kg) | 10–20 days | Diameter, coating, spools | ISO 9001; RoHS/REACH on request |

| Vendor B | ±7–10% UTS | Medium | 25–30 days | Limited | ISO 9001 |

| Vendor C | ±5–8% UTS | High | 15–25 days | Coating only | Basic compliance |

Options include diameter (0.10–1.00 mm), alloy (304/316L, high-carbon, nichrome), surface (bright/Zn/Sn/polymer), and packaging (DIN spools, coils). Many customers say the polymer-coated Cutting Wire noticeably reduces squeal on foam lines—small win, big relief. One EPS shop in Zhejiang switched to a 0.30 mm nichrome variant: cut speed rose ≈12%, and breakage dropped from 7 to 2 per week after they matched tension to 55% of UTS and stabilized heat via closed-loop drivers.

Standards referenced: ASTM A313 (stainless spring wire), EN 10270-1 (patented cold-drawn steel wire), ISO 6892-1 (tensile testing). Sample lot data: 0.30 mm 316L—diameter ±0.005 mm, UTS 1670 MPa, elongation 10.5%, salt spray 96 h (no red rust); high-carbon 0.50 mm—UTS 2100 MPa, torsion ≥25 turns. Food-contact declarations and RoHS/REACH reports can be supplied per order.

Bottom line: if you need consistent, easy-to-use Cutting Wire with fast tweaks for your line, this factory in Hebei is worth a call.

RELATED PRODUCTS