Navigating the dynamic world of metal mesh pricing requires an understanding of multiple variables and market influences. As a long-standing expert in the field, I’ve witnessed firsthand how this particular industry continues to evolve, affecting suppliers and consumers alike.

Metal mesh, renowned for its versatility and utility, finds application in a plethora of industries ranging from construction and automotive to filtration and decoration. This ubiquitous material, however, sees its pricing fluctuate based on several critical factors.

A significant influence on metal mesh pricing is the cost of raw materials. Commodities such as steel, aluminum, and copper, which are integral to the production of metal mesh, are subject to constant price changes due to market demand, geopolitical situations, and trade tariffs. For instance, a surge in construction projects might see an escalated demand for steel, directly impacting the pricing of steel-based metal mesh products.

Furthermore, production technology and energy costs play pivotal roles. Advanced technologies that enhance the strength and flexibility of metal mesh can drive up production costs, thereby influencing final market prices. Similarly, the energy-intensive nature of material production means that fluctuations in energy prices—electricity and fuel—have a direct effect on pricing.

An often-overlooked aspect is the regulatory landscape. Stricter environmental regulations and certifications around production processes, especially concerning emissions and waste management, can add layers of cost to manufacturers. Compliance with these regulations, albeit necessary for sustainable production, may influence pricing strategies.

Another aspect to consider is logistics and transportation. The global nature of the metal mesh market requires efficient supply chains. Costs associated with shipping, storage, and handling of materials contribute to the final product price. Economic disruptions, such as port delays or increased fuel prices, can lead to unforeseen price adjustments.

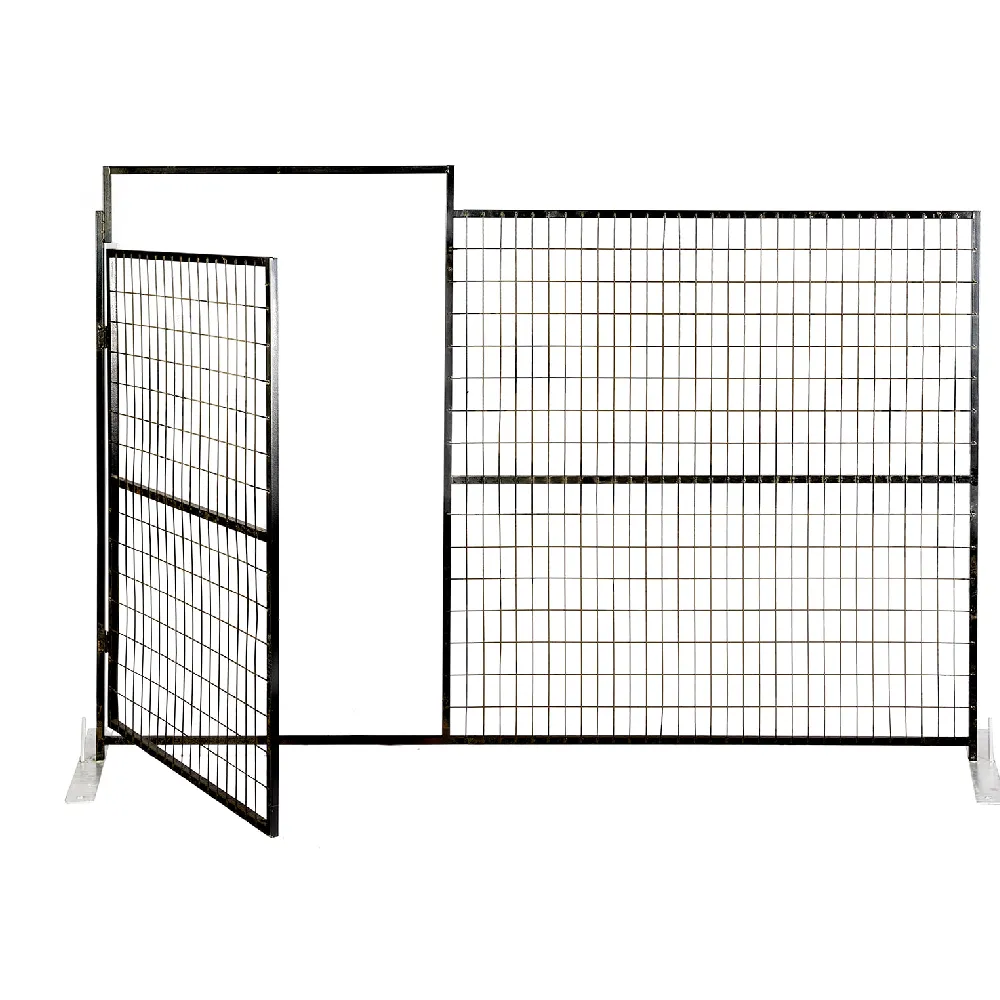

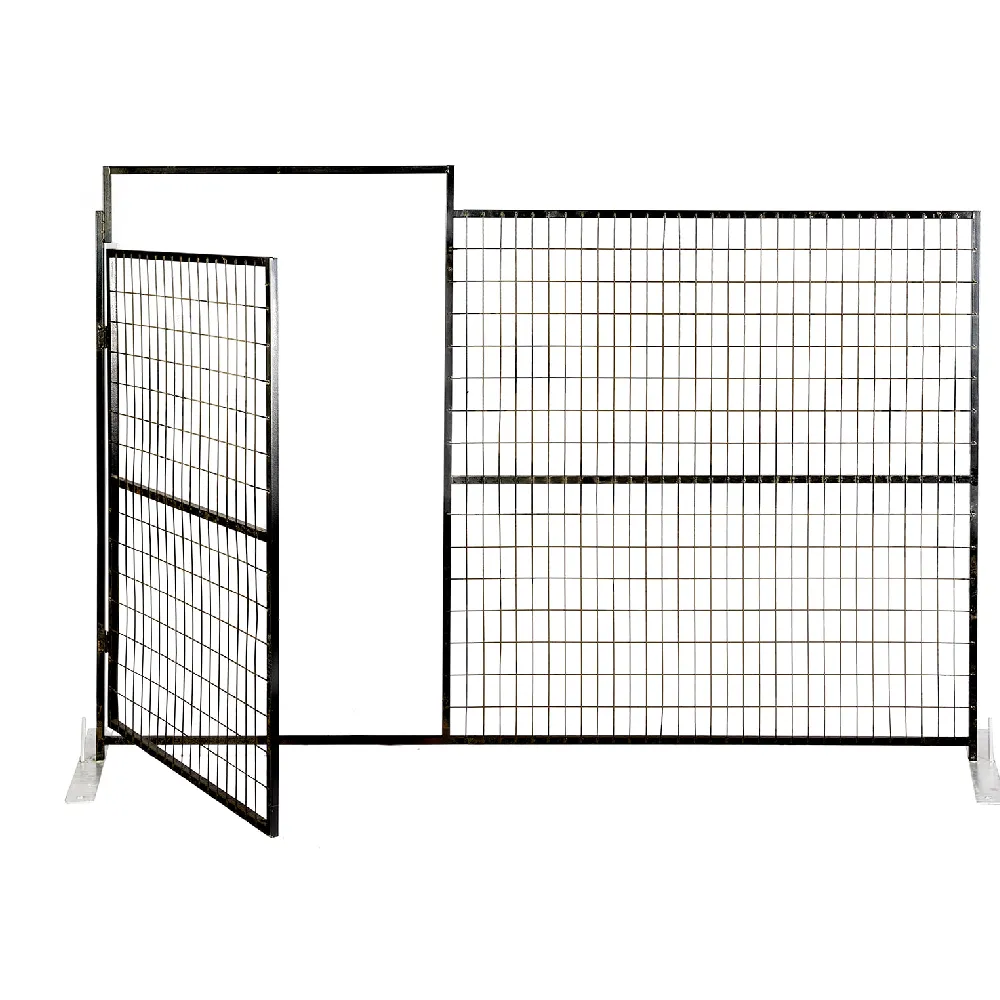

metal mesh price

In terms of industry trends, there's a growing inclination towards customized metal mesh solutions. Increased demand for specific applications—such as anti-dust meshes in electronic devices or high-durability meshes for architectural use—requires bespoke production processes, which can add a premium to standard pricing.

Transparency and communication between suppliers and buyers are crucial. An informed buyer can make strategic decisions with a clear understanding of market trends and price determinants. Suppliers who offer transparency concerning their pricing models, and who can articulate the impact of various factors on their pricing, build trust and credibility.

An advantageous approach for those looking to navigate metal mesh pricing is adopting forward contracts or hedging strategies. These financial instruments can aid businesses in locking current rates, protecting against potential future increases due to market volatility.

Lastly, leveraging technological advancements, such as AI-driven analytics and predictive modeling, can provide industry players with insights into price developments and potential market disruptions, enabling them to make data-driven decisions.

The landscape of metal mesh pricing is a reflection of a multitude of interconnected factors. For businesses and end-users, staying informed about these elements, and understanding the broader market dynamics, can facilitate smarter purchasing decisions, ensuring that they capture value while aligning with their financial and operational goals.