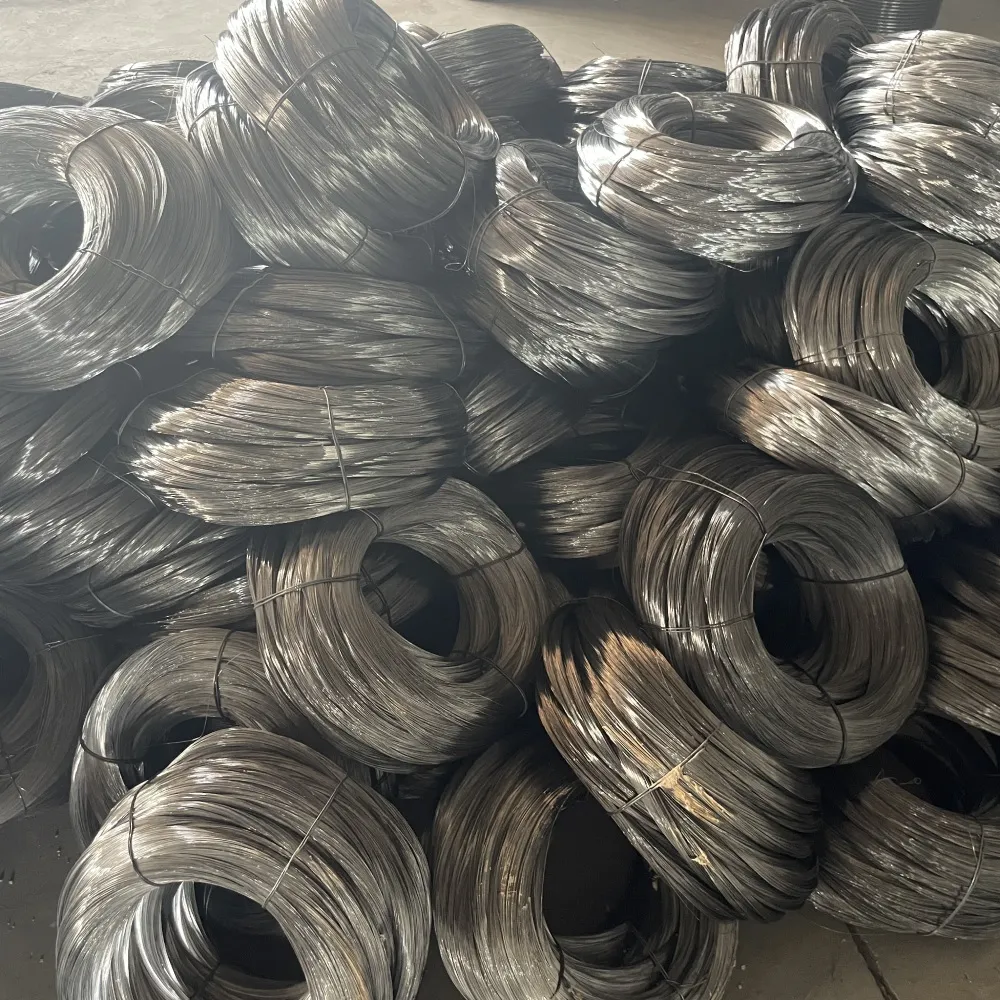

Last month I was in Hebei, out by the east side of Baoheng Road in Zhaobazhuang Village, Tangfeng Town, Shenzhou City, and watched coils come off the annealing line with a dark satin finish. That was my reminder that black iron wire is still the quiet backbone of construction and recycling yards. It’s marketed locally simply as “Black Wire,” but the performance is what people remember—good elasticity, consistent draw, forgiving to bend.

At its core, black iron wire is low-carbon steel wire (typically SAE 1006/1008) drawn to size, then furnace-annealed to recover ductility. The Hebei line I toured runs a pretty standard flow:

| Parameter | Spec (≈, real-world use may vary) |

|---|---|

| Diameter range | 0.8–5.5 mm (20–4 gauge) |

| Tensile strength after anneal | 350–550 MPa |

| Elongation | ≥ 15–25% |

| Coil/spool | Small coils 1–50 kg; master coils 500–1000 kg |

| Finish | Black annealed; light oil or dry |

| Standards touchpoints | ASTM A853 (carbon steel wire); EN 10218-1/2 (general + wire drawing) |

Advantages folks mention: forgiving bends, steady coil payoff, and cost. Not glamorous, but reliable. Service life indoors is typically 3–5 years; outdoors it depends heavily on humidity and salt exposure (I’ve seen black iron wire hold up fine under tarps, and fail fast on coastal sites—fair warning).

Routine tests include tensile/elongation (per ASTM A853 sampling), reverse-bend, diameter tolerance, and surface continuity. A typical tensile pull I saw in Hebei: Ø1.2 mm at ≈ 420 MPa TS and 22% elongation—right down the fairway. Plants usually run ISO 9001 systems and can provide RoHS/REACH statements (no coating, so it’s straightforward).

| Vendor | Range | Certs | Lead time | Notes |

|---|---|---|---|---|

| Tike Metal (Origin: East side of Baoheng Road… Hebei) | 0.8–5.5 mm; coils/spools | ISO 9001; RoHS/REACH statements | 7–15 days (stock); 20–30 days custom | Stable anneal curves; good coil build |

| Importer A (mixed mills) | 1.2–4.0 mm | ISO 9001 (varies) | 20–45 days | Inconsistent payoff on some lots |

| Local Distributor B | Common sizes only | — | Immediate from stock | Convenient, premium pricing |

Construction (SE Asia): Switching to Ø1.0 mm black iron wire with softer anneal cut rebar tying time ≈8% (crew feedback: “fewer snaps, easier twist”).

Recycling (EU MRF): 12-gauge black iron wire on 25 kg spools reduced changeovers by ~12 per week; bale integrity unchanged after 72-hour dwell.

Citations:

RELATED PRODUCTS