Iron tie wire, a fundamental component in various industrial and construction activities, serves a multitude of purposes, from securing frameworks to facilitating efficient packaging solutions. A deep dive into its characteristics and applications not only highlights the wire’s unmatched utility but also provides insights into why it remains a pivotal element in numerous sectors.

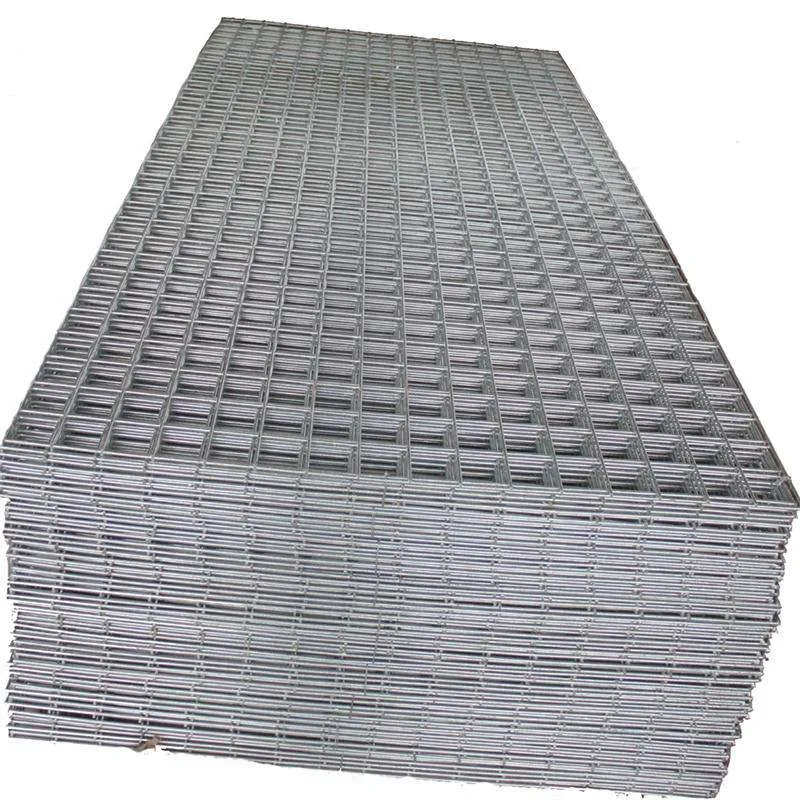

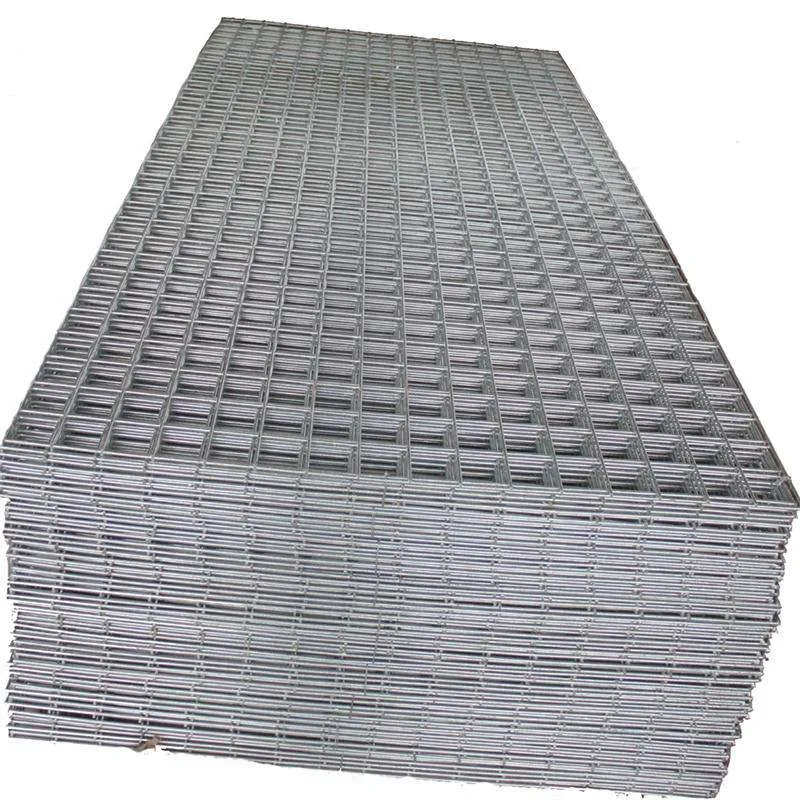

At its core, iron tie wire is highly regarded for its tensile strength and flexibility. These properties make it the ideal choice for tasks that require both durability and ease of manipulation. Unlike other materials, the inherent strength of iron ensures that the wire can withstand substantial pressure and weight without compromising its structural integrity. This makes it exceptionally useful in construction, where it is employed to secure rebar, ensuring stability and safety in building foundations.

Moreover, the versatility of iron tie wire makes it a preferred option in agriculture and landscaping. Farmers often rely on it to secure plants and vines to supports, promoting organized growth and maximizing space efficiency. In landscaping, the wire helps to form and hold shapes in topiary, ensuring the aesthetic appeal and structure of garden art.

From an industrial perspective, iron tie wire's application in packaging and transportation cannot be overstated. It is used extensively to bind products, ensuring their safe transit from manufacturers to retailers. This not only helps in maintaining the integrity of the goods but also in reducing the risk of loss or damage, thereby fostering trust with end consumers and partners along the supply chain.

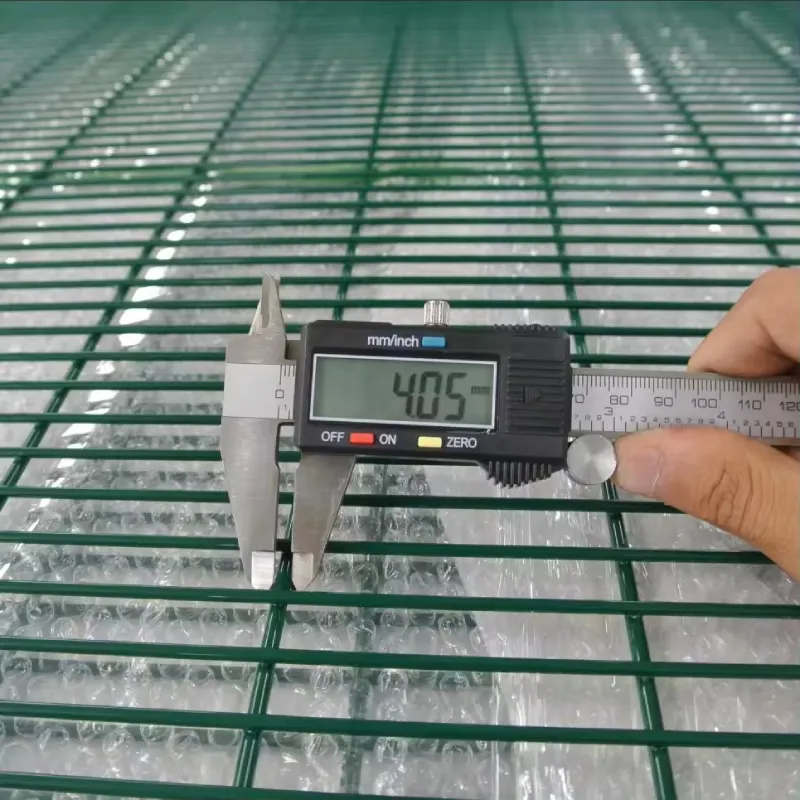

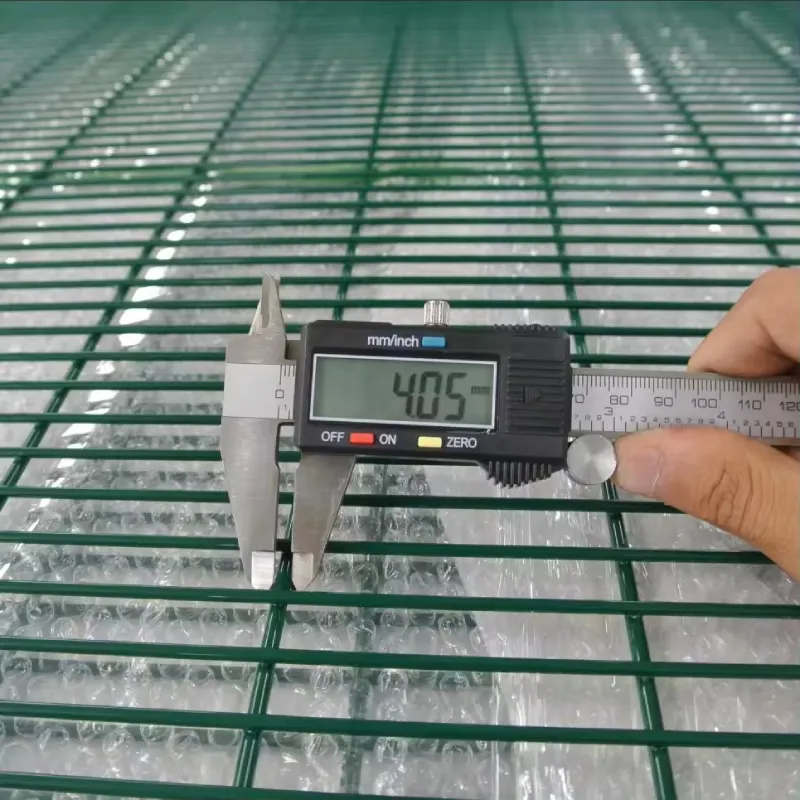

The expertise surrounding the manufacturing and treatment of iron tie wire also enhances its appeal. The process typically involves drawing the iron through a series of dies to achieve the desired thickness and strength. Hardened through precise heat treatment protocols, the wire exhibits enhanced resilience against environmental stresses such as humidity and fluctuating temperatures. The meticulous attention to production quality underscores the expertise required to produce wire that meets international standards.

iron tie wire

One might question the environmental impact of utilizing iron tie wire, considering the growing emphasis on sustainable practices. It's noteworthy that iron, as a material,

is fully recyclable. The wire can be repurposed and reused without significant degradation of its properties. This recycling capability aligns with the increasing demand for eco-friendly materials, adding to the wire's authoritative standing in material selection for green construction projects.

Additionally, its affordability compared to alternative binding solutions underscores its value proposition. The cost-effectiveness of iron tie wire does not compromise performance, ensuring wide accessibility across varied economic landscapes globally. This economic edge reinforces its authoritative presence as a reliable choice among contractors, farmers, and manufacturers.

Trustworthiness is further solidified by long-term usage and positive feedback in diverse industries. Users report high satisfaction rates due to its reliability and performance consistency. Many providers adhere to stringent quality assurance protocols, offering warranties and support services that guarantee user satisfaction and enhance brand loyalty.

In conclusion, iron tie wire remains an indispensable material across multiple sectors owing to its superior strength, versatility, and sustainable attributes. Its widespread acclaim is backed by decades of trusted use, professional expertise in manufacturing, and evolving innovations that keep it relevant in modern applications. As industries continue to progress, iron tie wire stands as a testament to the enduring importance of robust, flexible solutions.