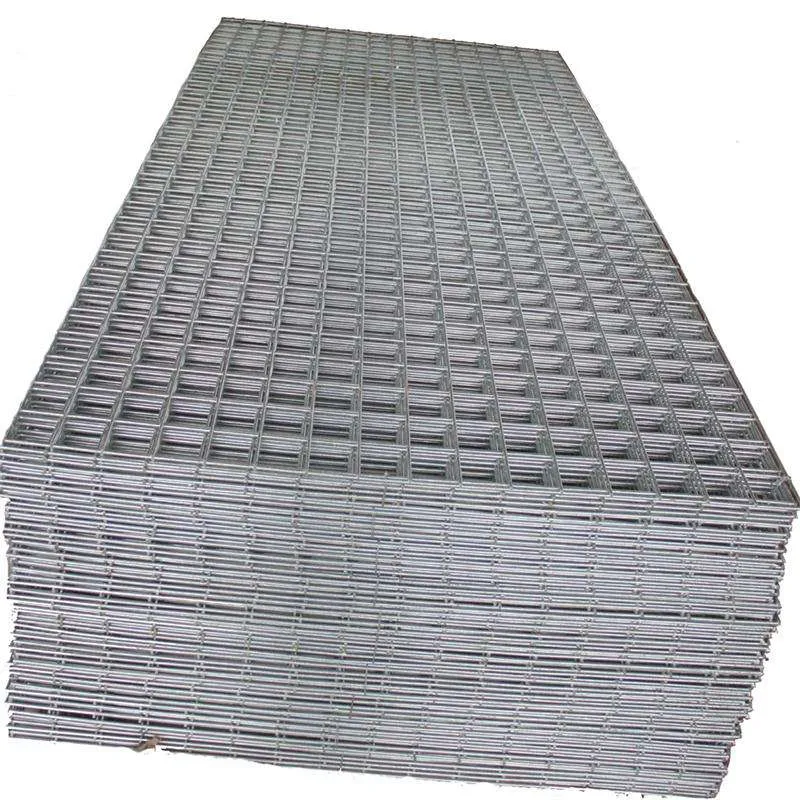

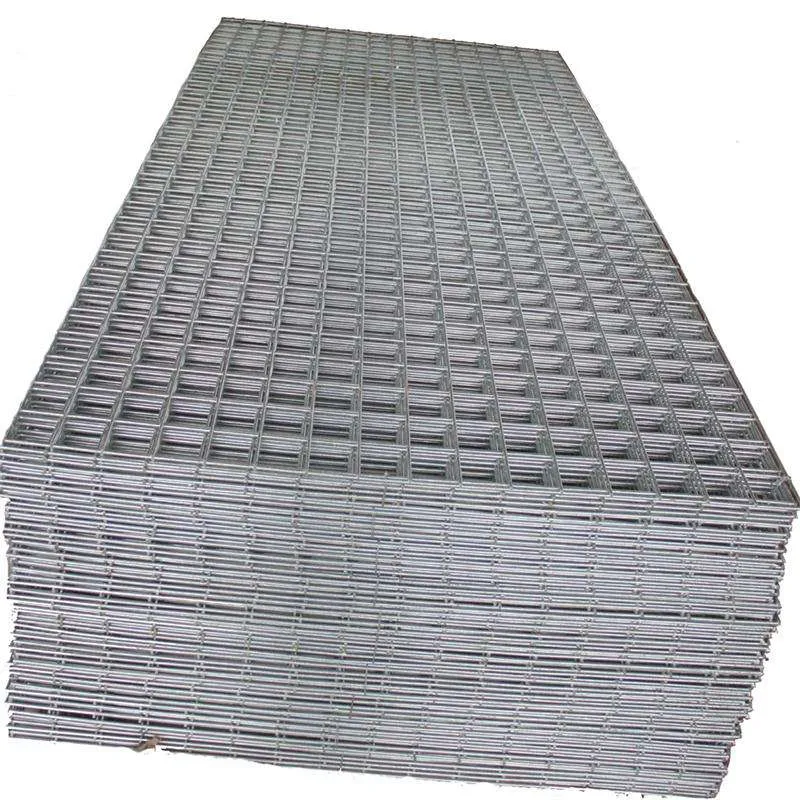

Industrial metal mesh is a versatile material that has transformed numerous industries with its vast array of applications. Traditionally, metal mesh has been used for simple fencing or structural support, but the modern industrial landscape reveals far more innovative uses. This evolution is due primarily to its unique properties, including durability, flexibility, and high tensile strength.

One of the most critical sectors benefitting from industrial metal mesh is the architectural and construction industry. Architects and designers are continuously pushing the boundaries of creativity and sustainability, and metal mesh provides a perfect blend of both. Its openness allows natural light and air to penetrate buildings, promoting energy efficiency and reducing the reliance on artificial lighting and ventilation. Furthermore, metal mesh is an excellent choice for creating aesthetically pleasing facades and partitions, offering both functionality and style.

In the realm of transportation, industrial metal mesh plays a pivotal role in manufacturing and safety. It is used in the production of vehicle grilles, filters, and ventilated panels due to its robustness and lightweight nature. The aerospace industry, in particular, relies on metal mesh for its unparalleled strength-to-weight ratio, which is critical for fuel efficiency and overall performance. These attributes not only enhance the safety of vehicles but also significantly contribute to the operational efficiency of transport systems.

The agricultural sector also reaps the benefits of industrial metal mesh. This durable material is employed for grain storage and drying, as well as in livestock enclosures. Its ability to withstand harsh environmental conditions ensures long-lasting performance, minimizing maintenance costs and reducing waste. Farmers have reported increased productivity and improved crop quality, attributing these successes to the superior aeration and protection provided by metal mesh.

industrial metal mesh

Industrial metal mesh is indispensable in the filtration industry. Its precise pore sizes allow for effective separation of particles in liquids and gases, making it an ideal choice for water treatment, chemical processing, and air purification plants. Industries dealing with hazardous materials rely heavily on the reliability of metal mesh filters to ensure the safety and integrity of their processes. This level of trust is built on decades of proven performance and a deep understanding of filtration technology.

From a manufacturing perspective, the flexibility and adaptability of industrial metal mesh make it a cost-effective solution. The mesh can be tailored to specific requirements, whether it is being used for a simple screen or a complex component in sophisticated machinery. Manufacturers appreciate the ease of installation and its compatibility with other materials, which streamlines production and enhances product quality.

Furthermore, the recyclability of metal mesh aligns with the global shift towards sustainable practices. Companies across various industries are recognizing the importance of reducing their environmental footprint, and the use of recyclable materials like metal mesh is a significant step in that direction. It not only addresses corporate responsibility but also meets the increasing consumer demand for sustainable products.

Overall, industrial metal mesh stands out as a material of choice across multiple industries due to its unmatched combination of strength, versatility, and sustainability. Its role in modern industrial applications highlights the importance of selecting materials that can adapt to the rapidly changing demands of the market, improve efficiency, and foster innovation. As industries continue to evolve, the reliance on trusted materials like industrial metal mesh ensures they are well-equipped to tackle future challenges. The continuing development of this material is a testament to its essential position in the industrial world, proving time and again that it is an invaluable asset in both traditional and modern applications.