The Unmatched Benefits of Hot Dip Galvanized Steel Grating for Modern Industries

Hot dip galvanized steel grating is a critical component in various industrial applications, renowned for its durability, strength, and corrosion resistance. With an ever-growing demand across sectors such as construction, manufacturing, and infrastructure development, understanding the benefits and applications of this material can be invaluable. Drawing on years of experience and expert insights, this article aims to explore the unique advantages of hot dip galvanized steel grating and its significance in industrial settings.

One of the most remarkable features of hot dip galvanized steel grating is its exceptional longevity. The galvanization process involves immersing the steel in molten zinc, creating a robust barrier against rust and corrosion. This protective layer is not only long-lasting but also self-healing, as it can combat damages and scratches by forming a zinc oxide layer upon exposure to moisture. This intrinsic property ensures that the grating has a prolonged service life, significantly reducing the need for frequent maintenance or replacements.

Professionals working in harsh environments, such as offshore oil rigs or chemical plants, frequently opt for hot dip galvanized steel grating due to its resilience under extreme conditions. The robust protection against corrosion ensures that the structural integrity of platforms, walkways, and drainage covers is maintained, even when exposed to saltwater or industrial chemicals. This translates to lower operational costs and enhanced safety, as the risk of collapse or failure is markedly reduced.

Beyond its durability, hot dip galvanized steel grating is revered for its high load-bearing capacity. In industrial settings where heavy machinery or high foot traffic is prevalent, the grating must withstand significant pressure without compromising stability. The strength-to-weight ratio of galvanized steel grating offers an optimal balance, providing robust support while keeping structural weight at a minimum. This not only enhances ease of installation but also supports sustainability by reducing material requirements without sacrificing safety or performance.

hot dip galvanized steel grating

From an environmental perspective, hot dip galvanized steel grating is a responsible choice. Its manufacturing process is resource-efficient, minimizing waste and energy consumption. Additionally,

galvanized steel is 100% recyclable, supporting industrial sustainability goals. Industries focused on reducing their carbon footprint benefit from integrating such eco-friendly materials into their operations, reflecting a commitment to environmental stewardship and regulatory compliance.

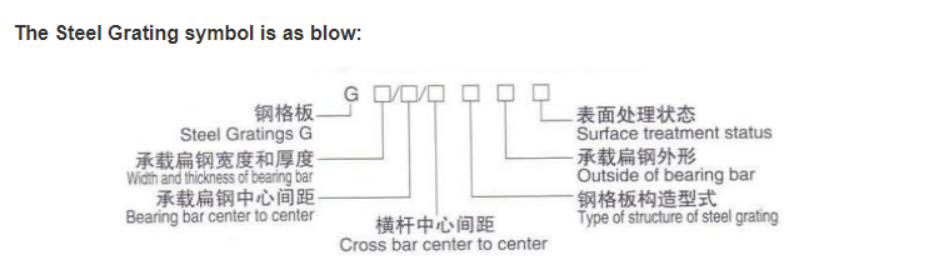

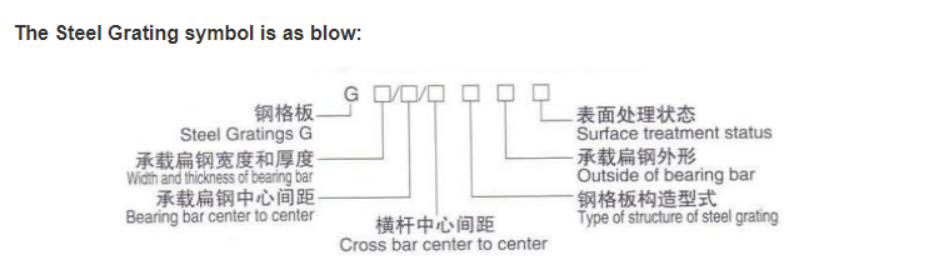

In terms of design flexibility, hot dip galvanized steel grating offers numerous configurations and sizes to suit varying operational needs. Customized solutions are readily available, allowing businesses to address specific functional requirements or aesthetic preferences. Whether for industrial floors, stair treads, or ventilation grilles, the adaptability of galvanized steel grating ensures seamless integration with existing structures or new projects.

Furthermore, the application of hot dip galvanized steel grating enhances workplace safety. Its non-slip surface significantly reduces the risk of accidents in areas prone to oil, water, or chemical spills. This safety feature is crucial in maintaining a secure work environment, underscoring the importance of choosing materials that not only meet functional demands but also prioritize personnel safety.

Expert testimony and authoritative data support the trustworthiness of hot dip galvanized steel grating as an industry-standard product. Manufacturers adhere to stringent quality controls and standards, such as ISO certifications, to ensure reliability and performance. This commitment to quality underpins the reputation of galvanized steel grating as a dependable solution for industrial challenges.

In conclusion, hot dip galvanized steel grating stands out as a superior choice for industries seeking durable, versatile, and environmentally friendly solutions. Its ability to withstand harsh environments, support substantial loads, and ensure safety makes it an indispensable asset across various applications. As industries evolve and demand resilient infrastructure, investing in hot dip galvanized steel grating promises long-term benefits and superior performance, reaffirming its status as an industry leader.