If you work in fencing, concrete reinforcement, or aquaculture, you’ve probably handled Hot Dipped Galvanized welded Wire Mesh more times than you can count. To be honest, not all mesh is created equal. Coating route, wire chemistry, weld settings—these are the quiet variables that decide whether your fence looks new in year six or starts flaking by winter two.

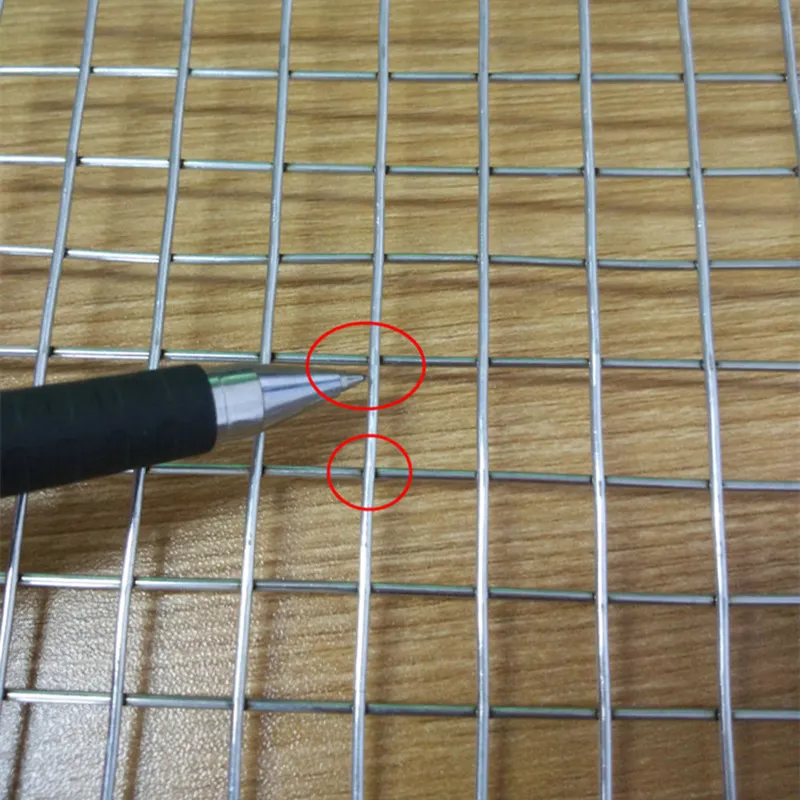

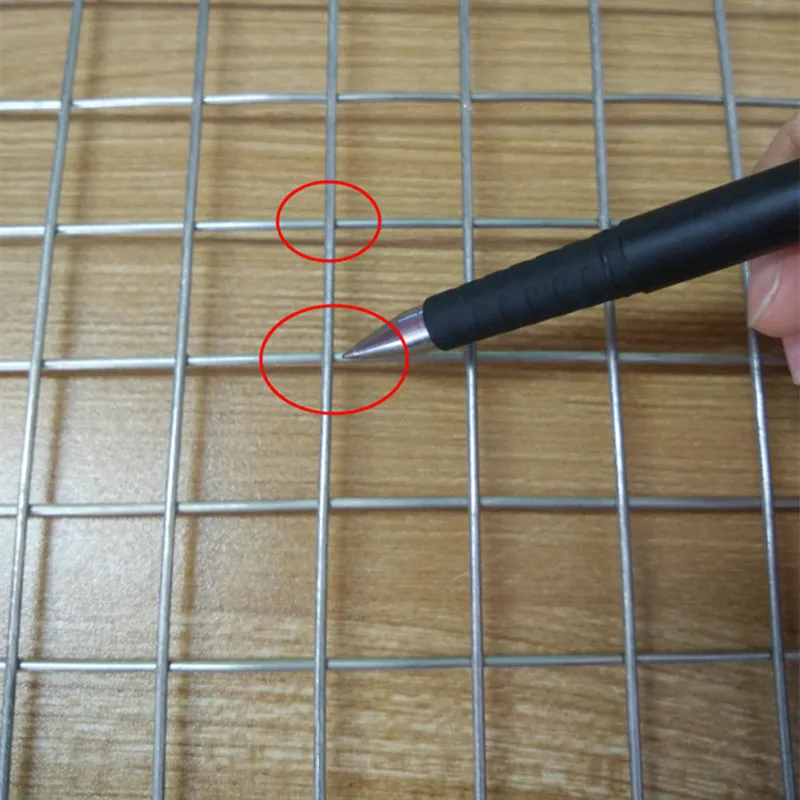

We’re seeing a steady shift toward heavier zinc weights and pre-galvanized (GBW) wire that’s hot-dipped before welding—exactly what this product is. Actually, that choice is deliberate: you get a thick, uniform zinc layer on the wire. Yes, the welds can temper the coating at the nodes, but with robust zinc mass, service life stays strong. Many customers say this strikes the best price–performance balance compared with galvanizing the entire panel after welding (GAW).

| Parameter | Typical Range (≈) | Notes |

|---|---|---|

| Wire diameter | 1.2–4.8 mm | Heavier gauges for panels/industrial yards |

| Mesh opening | 1/4"–2" (6.35–50.8 mm) | Custom spacing available |

| Zinc coating mass | ≈ 180–300 g/m² | Higher for coastal requests |

| Tensile strength | 380–550 MPa | Balanced for weldability |

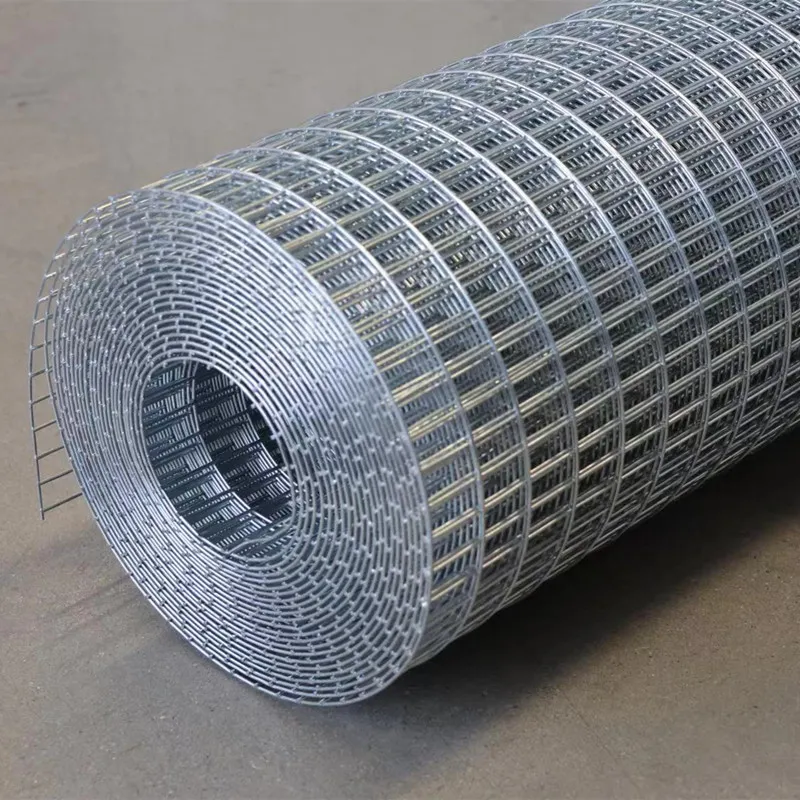

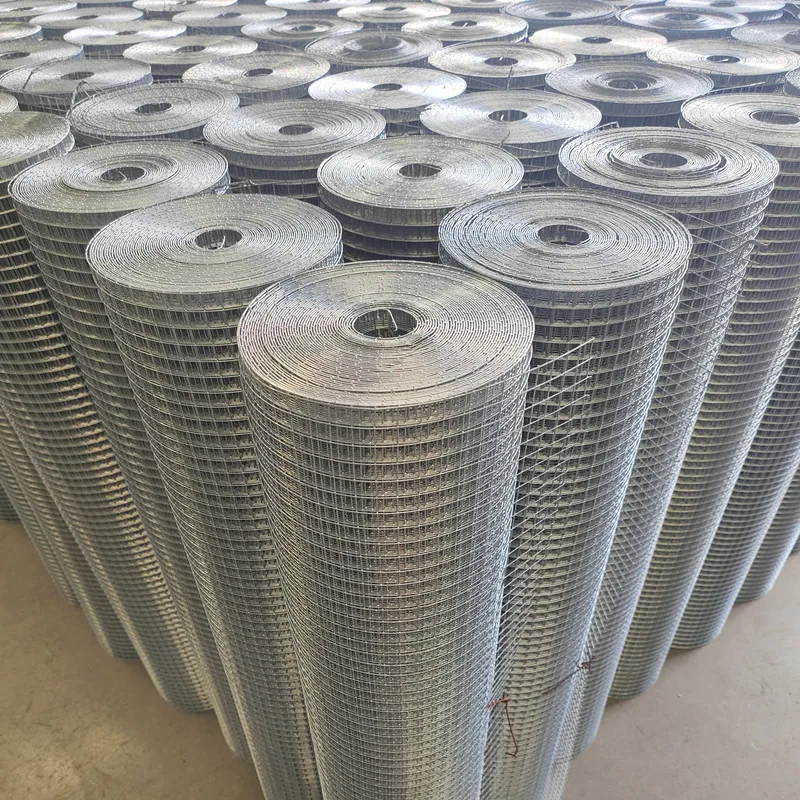

| Formats | Rolls 0.9–1.8 m; Panels 1×2 m, 1.2×2.4 m | Other sizes on request |

| Service life | ≈ 8–20 years | Environment-dependent |

Lab snapshots: salt spray (ASTM B117) has clocked 480–720 h before red rust at cut edges in typical GBW builds—field mileage varies with pollution and salt load. Customers in mildly coastal zones report “still clean” at year 6, which frankly aligns with what we’ve seen.

Origin matters too: these meshes are produced near the East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui, Hebei—an area that lives and breathes wire and mesh. It shows in the consistency.

| Vendor | Lead time | Zinc mass (≈) | Certs | QC Testing |

|---|---|---|---|---|

| Tike Metal (Hebei) | 10–20 days | 180–300 g/m² | ISO 9001 | ASTM A90, B117 reports per lot |

| Generic Importer A | 30–45 days | ≈ 120–200 g/m² | Supplier-declared | Spot checks only |

| Local Mill B | 7–15 days | ≈ 150–250 g/m² | ISO 9001 | In-house only |

A mid-size berry farm near brackish water opted for Hot Dipped Galvanized welded Wire Mesh rolls, 2" opening, 2.8 mm wire, zinc ≈ 260 g/m². Installation was brisk; posts at 2.5 m centers worked fine. After 30 months, only light dulling—no red rust at welds. The farm manager told us, “Honestly, zero maintenance so far.” That’s what you want.

You can tweak opening size, wire gauge, roll vs panel, and zinc mass. For splash zones or fertilizer-heavy fields, ask for the upper zinc band and tighter QA on weld nugget size. If vandal resistance is a worry, step up gauge and panelize. And if you need color, a light powder topcoat over Hot Dipped Galvanized welded Wire Mesh isn’t overkill—it extends life, surprisingly often at modest cost.

Citations:

RELATED PRODUCTS