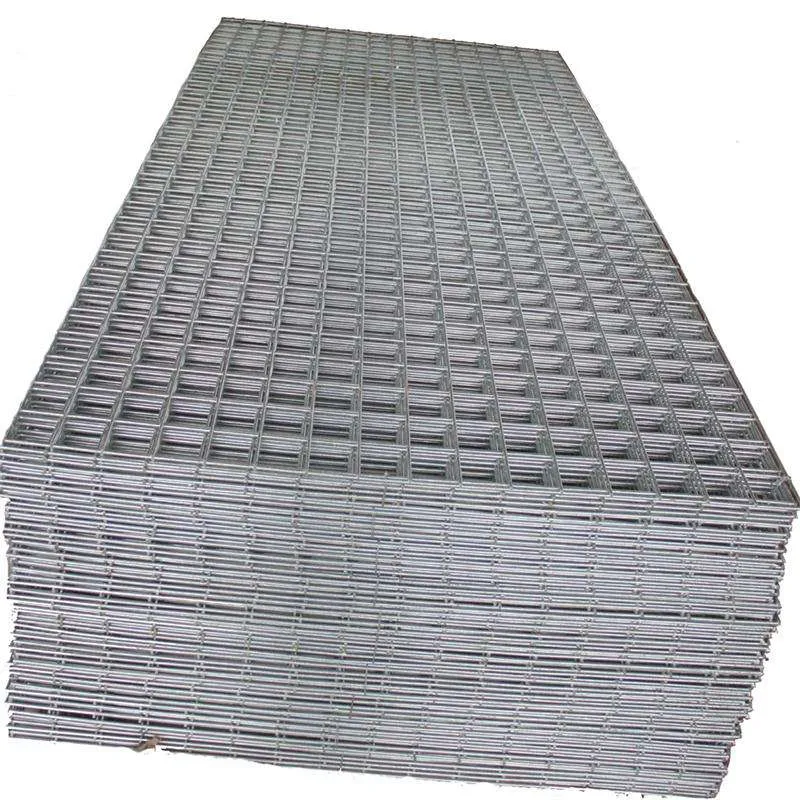

Hot Dipped Galvanized Welded Mesh Panel is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire mesh. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

A Hot Dipped Galvanized Welded Mesh Panel is a rigid sheet made by resistance welding low-carbon steel wires into a grid, then immersing the entire panel in molten zinc. The hot-dip process forms a metallurgical bond that coats welds, cut ends, and intersections—delivering superior corrosion resistance versus pre-galvanized or electro-galvanized alternatives. For B2B buyers in fabricated metal products and the manufacturing of metal wire mesh, this translates to stable performance, longer service life, and consistent dimensional accuracy across projects.

Across factories, logistics hubs, and infrastructure projects, hot-dipped galvanized welded panels are specified for perimeter fencing, machine guarding, warehouse partitions, shelving and racking sides, animal enclosures, ventilation and HVAC guards, and construction reinforcement. Their rigidity and corrosion protection make them a go-to choice for outdoor and high-traffic environments.

The total cost of ownership favors hot-dipped galvanized panels because the robust zinc layer protects welds and edges, reducing repainting and replacement cycles. Installation speed and low maintenance demands lower lifecycle labor costs, while consistent panel flatness reduces rework during integration into frames and fence lines. For B2B buyers, this means predictable budgets and fewer maintenance shutdowns.

Sustainability priorities in manufacturing emphasize longer-lasting materials, circularity, and compliance with regulations such as REACH and RoHS. Hot-dipped galvanized steel contributes by extending service life—reducing replacements and embodied carbon over the asset’s lifetime—while both steel and zinc are fully recyclable. This aligns with end users seeking durable, low-maintenance infrastructure in utilities, transport, logistics, and agriculture.

Hot Dipped Galvanized Welded Mesh Panel delivers the durability, dimensional stability, and corrosion resistance B2B decision makers need across fabricated metal products and the manufacturing of metal wire mesh. With consistent quality and customization, SHENZHOU TIKE METAL CO., LTD. is a reliable partner for industrial, construction, and infrastructure applications. Ready to engineer your next project with confidence?

RELATED PRODUCTS