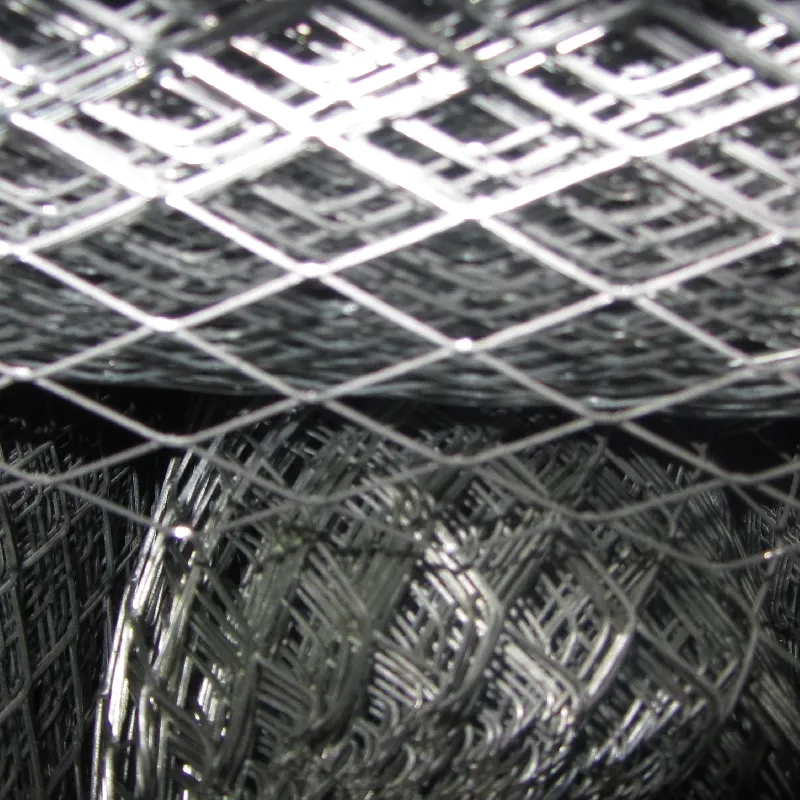

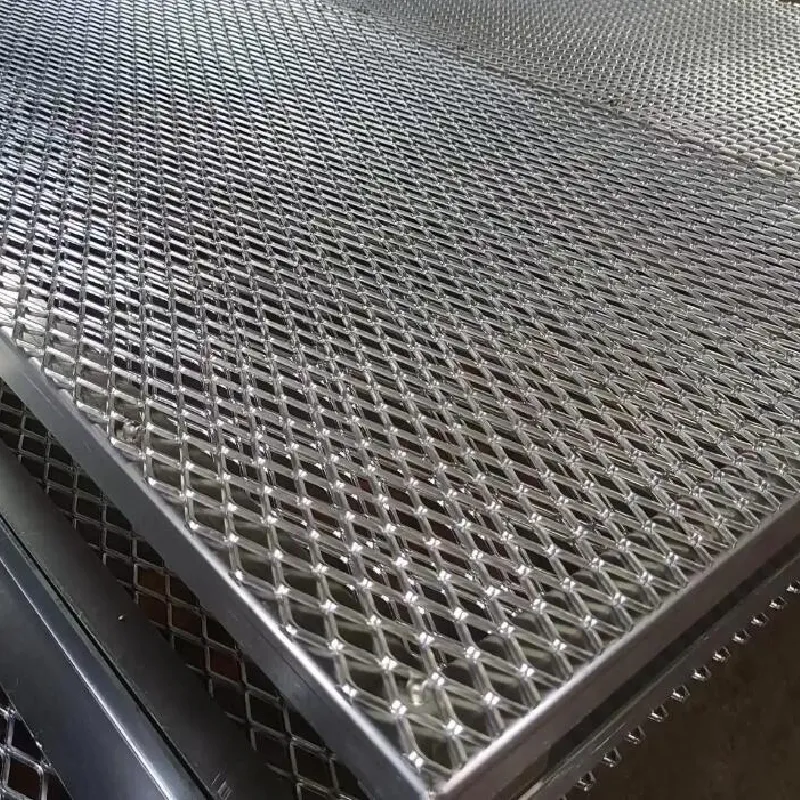

1. Overview: What is Expanded Metal Mesh?

Expanded Metal Mesh is produced by simultaneously slitting and stretching metal sheets, resulting in a mesh-like pattern composed of diamond-shaped openings. This unique unibody structure (no welds or weak points) delivers high strength-to-weight ratios, excellent rigidity, and reliable performance across countless modern engineering and architectural applications. Available in materials such as carbon steel, stainless steel, aluminum, copper, and more, Expanded Metal Mesh provides excellent air/light flow, security, and aesthetics.

2. Industry Trends: The Evolving Market for Expanded Metal Mesh

The global Expanded Metal Mesh market has seen significant growth over the past decade, driven by rising infrastructure projects, innovations in building design, industrial protection systems, and urban beautification initiatives. According to MarketsandMarkets and Academic Forum Reports, the demand for advanced mesh specifications—especially mill-finished carbon steel and stainless steel—has increased substantially in the Americas, Europe, and Asia-Pacific. Rapid innovation in mesh processing, anti-corrosion treatments, and design customization is a key future trend.

| Region |

2023 Market Share (%) |

Typical Applications |

Growth Rate (2022-2028, CAGR) |

| Asia-Pacific |

35% |

Infrastructure, Industrial, Security Grills |

6.2% |

| Europe |

28% |

Façades, Railings, Furniture, Filtration |

5.4% |

| North America |

24% |

Architectural, Walkways, Gratings, Fencing |

4.8% |

| Middle East & Africa |

8% |

Perimeter Security, Sunshades |

4.1% |

| Latin America |

5% |

Civil, Residential, Decorative |

3.7% |

- 2023 Market Size: USD 2.4 Billion

- Expected 2028 Market Size: Over USD 3.3 Billion

- Key Drivers: Green architecture, rising urban security, prefabricated construction, design innovations

- Sources: MarketsandMarkets, SAGE Journals

3. Technical Parameters of Expanded Metal Mesh

The core advantages of Expanded Metal Mesh stem from its customizable technical parameters. Industry standards from ASTM F1267, EN 13241-1 specify crucial metrics:

| Parameter |

Common Range |

Industry Standard |

Description |

| Material |

Carbon steel, SS304/316, Aluminum, Copper |

ASTM, EN specs |

Base metal type |

| Mesh Thickness |

0.3mm ~ 8mm |

EN 10346, ASTM 123-19 |

Sheet thickness after expansion |

| SWD / LWD (Short/Long Way of Diamond) |

3mm × 6mm ~ 120mm x 300mm |

Customized |

Opening size directionally |

| Strand Width |

0.5mm – 8.5mm |

Customer spec |

Metal strip between mesh openings |

| Overall Width |

0.5m ~ 2.5m |

Industry standard & custom |

Full width of mesh panel |

| Surface Finish |

Mill Finish, Galvanized, Powder Coated |

ISO 9227 |

Corrosion protection, aesthetics |

| Open Area Ratio |

45% ~ 90% |

ASTM E2016-15 |

Light/air transmission ratio |

4. Applications of Expanded Metal Mesh

Versatile, robust, and aesthetic—Expanded Metal Mesh serves a broad spectrum of applications across multiple sectors:

- Security and Safety: Window guards, fencing, machine protection, stair treads, safety barriers, anti-slip walkways

- Architecture and Façade: Decorative panels, curtain walls, sunshades, suspended ceilings, facades, interior partitions

- Industrial/Filtration: Catalyst supports, filters, air & liquid filtration, battery enclosures

- Infrastructure: Gratings, trench covers, bridge walkways, highway guardrails, cable trays

- Automotive & Transportation: Grilles, radiator covers, train/ramp floorings, luggage racks

- Furniture & Design: Shelves, storage baskets, art installations, public seating

- Energy: Battery grids, solar panel supports

Case Study: TIKE Metal's mill-finish Expanded Metal Mesh has been widely deployed in international transportation infrastructure, combining anti-corrosion surface finishes with custom SWD/LWD patterns for project-specific requirements. (ScienceDirect Technical Review)

5. Manufacturing Process of Expanded Metal Mesh

The core behind the strength and cost-effectiveness of Expanded Metal Mesh lies in its manufacturing process. This involves:

- Sheet Selection: Certified raw metal sheets (carbon steel, stainless, alu) are chosen as per desired finish and strength.

- Slitting: Precision dies cut slits into the sheet at exact intervals using high-tonnage press.

- Expanding: The sheet is simultaneously stretched so the slits form uniform diamond or hexagonal openings.

- Finishing: Surface treatments – mill finished, hot-dip galvanized, powder coated, anodized, etc. – for durability and corrosion resistance.

- Cutting/Flattening: Cutting to desired dimensions; optionally flattening by rolling for certain architectural uses.

Unlike welded meshes, Expanded Metal Mesh has no bonds/joins, thus providing enhanced structural integrity and load-bearing performance.

6. Why Choose Expanded Metal Mesh by SHENZHOU TIKE METAL CO., LTD.?

- Exceptional Expertise: Decades of precision engineering and production excellence.

- Authoritative Standards: Certified according to ASTM F1267, EN 13241-1, ISO 9001, and ISO 14001.

- Custom Engineering: Tailored mesh sheet, size, strand width, and surface specification options.

- Trusted by Global Clients: Provided high-quality Expanded Metal Mesh for Fortune 500, government, and landmark projects worldwide.

- Leading Technologies: Automated CNC expansion presses, laser measurement QC, sustainable eco-finishing lines.

Contact: info@tikemetal.com | View Full Product Details

7. Professional FAQ: Key Expanded Metal Mesh Technical Issues

Expert Answers to Frequently Asked Technical Terms

Q1: What materials are commonly used for Expanded Metal Mesh?

A1: Carbon steel (mill finish, galvanized), stainless steel (304/316), aluminum alloys, nickel, and copper are the most widely used materials because of their mechanical strength and corrosion resistance.

Q2: What do SWD and LWD mean in the context of Expanded Metal Mesh?

A2: SWD (Short Way of Diamond) and LWD (Long Way of Diamond) refer to the dimensions of mesh opening. Correct specification ensures strength and passage of light/air (Source).

Q3: How is surface finish selected for Expanded Metal Mesh?

A3: Surface treatments depend on application & budget: mill finish for interior, hot-dip galvanizing for corrosion-prone environments, powder coating for extended durability and aesthetics.

Q4: How does Expanded Metal Mesh compare in strength to welded wire mesh?

A4: Expanded mesh maintains native metal integrity, increasing its strength-to-weight ratio. Welded mesh may have weak points at joints. For high-stress zones, expanded mesh is often superior (Reference).

Q5: What are key installation standards for Expanded Metal Mesh?

A5: Comply with standards such as ASTM F1267 and check for structural framework support, recommended fastener spacing, and edge protection. Factory finishing minimizes onsite processing (ASTM Standard).

Q6: What is the maximum panel size for Expanded Metal Mesh?

A6: Industry maximum is typically 2.5m × 7.5m (customizable); larger panels may require extra framing/handling provisions. Contact manufacturer for size limits.

Q7: How does strand width affect Expanded Metal Mesh performance?

A7: Wider strands provide higher load capacity but reduce open area. Application (load-bearing vs. filtration/decor) determines optimal strand width selection.

8. Best Practices for Specifying Expanded Metal Mesh

- Clearly define application purpose—load bearing, aesthetics, security, filtration, airflow

- Choose proper base material and coating for intended environment (e.g., hot-dip galvanized for outdoor use)

- Specify open area percentage to balance security and transmission (light, air, etc.)

- Accurately state mesh size (SWD, LWD), strand width, and thickness

- If architectural, consult designer for desired visual pattern and surface color

- Request supporting technical documentation and installation guidance

- Unmatched technical support by certified engineers (10+ years average experience)

- Quick prototyping and fast global delivery—ISO9001 quality guarantee

- Strict compliance with international and project-specific standards

- Scalable production from hand samples to bulk orders

-

Contact us: info@tikemetal.com,

+86 180 3200 9599 (Phone), 0318-5299898 (Mobile)

10. Conclusion

With innovative material science, process control, and decades-long industry experience, Expanded Metal Mesh has become an essential element of modern construction, safety, and design. Whether applied to infrastructure, architecture, or industrial filtration, its advantages—strength, cost-effectiveness, sustainability, and beauty—make it a preferred choice around the globe.

For project consultation or to order premium Expanded Metal Mesh, partner with SHENZHOU TIKE METAL CO., LTD.—your authoritative expert in advanced mesh solutions.