Heavy duty steel bar grating stands as a quintessential component in the construction and industrial sectors due to its strength, versatility, and adherence to safety standards. As industries continuously evolve, the demand for reliable materials that guarantee durability in various applications has necessitated an in-depth focus on this specific type of grating.

Steel bar grating is established as one of the superior choices in environments where safety, load-bearing capacity, and corrosion resistance are crucial. Its robustness is primarily attributed to the construction process, which involves the highly precise forging process. This ensures that each bar maintains a perfect alignment, thereby enhancing the overall structural integrity. This meticulous manufacturing process underscores the material's ability to handle extreme weights and pressures, making it ideal for use in walkways, platforms, and stair treads across various industries.

One of the standout features of heavy duty steel bar grating is its exceptional load bearing capabilities. Engineered to provide maximum strength with minimal weight, it outperforms conventional flooring materials. Structurally, it can withstand substantial loads without compromising on safety. This is particularly critical in industrial settings such as oil rigs, power plants, and transportation terminals, where heavy machinery and foot traffic demand resilient flooring solutions.

Durability is another hallmark of heavy duty steel bar grating. Its inherent resistance to harsh environmental factors, such as severe weather conditions and corrosive substances, ensures longevity and reduced maintenance costs. In fact, galvanized finishes often applied to steel gratings further enhance their resistance against rust and corrosion, making them a worthwhile investment for long-term infrastructure projects.

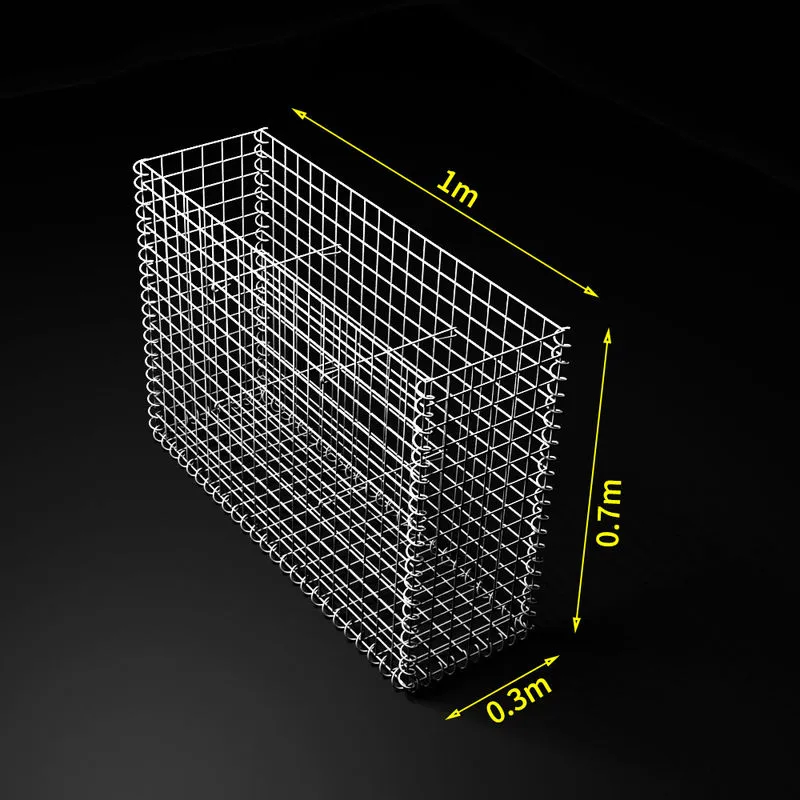

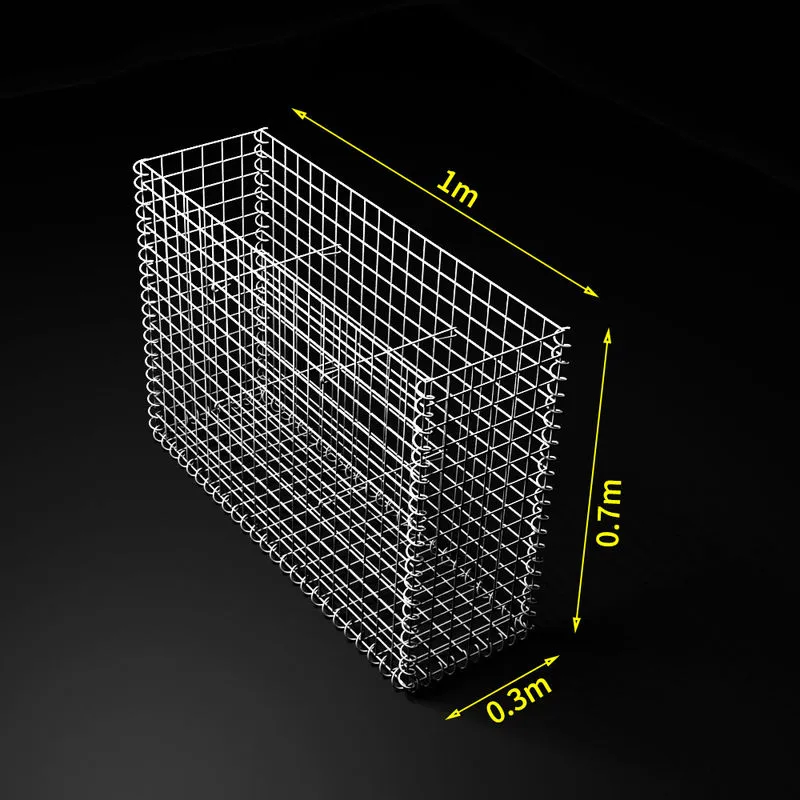

The design versatility of steel bar grating is another point of consideration for its widespread use. With various shapes and sizes available, it can be customized to meet specific project requirements. Whether the need is for serrated surfaces to provide extra traction or particular spacing between bars to allow debris to pass through, the adaptability of steel grating addresses numerous operational and aesthetic needs.

heavy duty steel bar grating

Safety, a paramount concern in any industrial setting, is also intrinsically linked to the choice of materials used.

Heavy duty steel bar grating leads with its anti-slip properties, particularly when surfaces are treated or serrated. This characteristic significantly reduces the chance of accidents, especially in wet or oily conditions, which are common in many industrial environments.

From an environmental perspective, steel is one of the most recycled materials globally. Opting for steel bar grating aligns with sustainable practices, encouraging the use of recycled content and supporting green building certifications. This commitment to sustainability does not detract from the material's performance—instead, it enhances its weight as a viable choice for eco-conscious organizations aiming to minimize their carbon footprint.

Moreover, the installation of steel bar grating is straightforward, reducing the time and labor costs associated with complex installation processes. The reduced installation time enhances project efficiency, ensuring that operations can commence without significant delays.

In conclusion, the use of heavy duty steel bar grating is a reflection of industry standards emphasizing experience, expertise, authoritativeness, and trustworthiness. By choosing this material, engineers and architects are assured of an expert-level product that encompasses reliability, durability, and safety. The comprehensive benefits it offers—ranging from superior load-bearing capacity to environmental sustainability—demonstrate its pivotal role in modern construction and industrial applications. The judicious choice of heavy duty steel bar grating ensures that infrastructure not only meets but exceeds the expected operational and safety standards, guaranteeing the trust and satisfaction of stakeholders involved.