Heavy duty metal screen mesh stands as a cornerstone in both industrial and domestic applications, offering unparalleled durability and versatility. For anyone keen on an efficient solution to various filtration and separation needs, the robust construction of these meshes is crafted to withstand the harshest environments while providing superior performance.

A prime example of its application can be found in industries such as mining and construction. Here, the demand for strong, resilient materials is constant,

and heavy-duty metal screen mesh doesn't disappoint. Its high tensile strength and corrosion resistance make it ideal for sieving rocks, gravel, and other coarse materials, helping to streamline operations while ensuring safety and precision.

Crafted from high-grade metals, these meshes are meticulously manufactured to meet specific needs. Stainless steel, one of the most popular materials used, provides excellent rust resistance, which is crucial for outdoor and marine applications. For industries where magnetic permeability is a concern, meshes made from specialized alloys like Monel are preferred, offering non-magnetic properties while maintaining strength.

In architectural design, heavy duty metal screen mesh is celebrated for its aesthetic and functional qualities. It is often installed as infill panels in balustrades or used in facades to add a touch of modern elegance. The mesh allows for an interplay of light and shadow, transforming spaces by enhancing visual interests without the need for heavy, opaque materials. This application underscores its versatility, marrying utility with style effortlessly.

The expertise involved in selecting the right mesh for a specific use cannot be overstated. Engineers and designers must consider variables such as aperture size, wire diameter, and the material of construction. For instance, fine mesh openings are crucial in water treatment facilities where precise filtration is necessary, while broader openings are suitable for agricultural use, where they function as effective barriers for pests without obstructing air circulation.

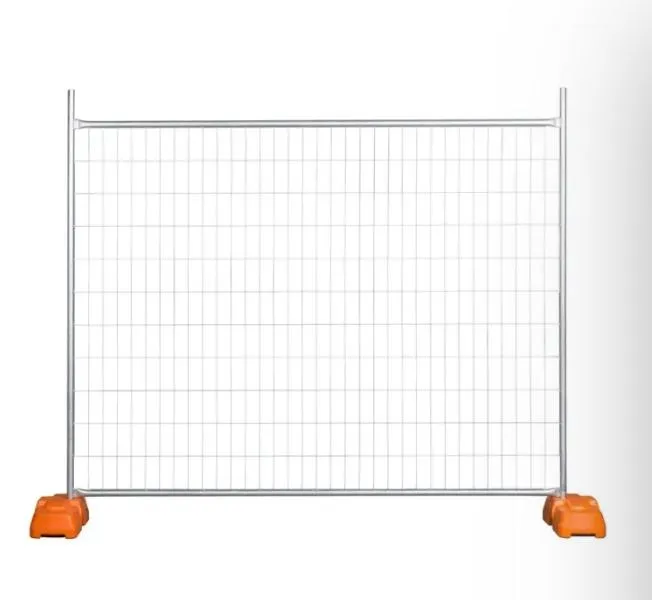

heavy duty metal screen mesh

Trustworthiness in heavy duty metal mesh products is achieved through rigorous testing and adherence to international standards such as ASTM and ISO. These standards ensure that the meshes meet required specifications for strength, corrosion resistance, and durability. Certifications from recognized bodies provide users with peace of mind, knowing that the products have been thoroughly vetted for quality and dependability.

Consulting industry experts is paramount for those new to utilizing heavy duty metal screen mesh. Experienced suppliers not only offer insights into the best products for specific applications but also provide after-sales support, ensuring that the mesh performs optimally over its lifespan. This relationship fosters a bond of trust, empowering users to maximize the utility of their investment.

Innovative advancements in manufacturing have further expanded the capabilities of heavy duty metal screen mesh. Laser cutting technology enables precise customization, allowing for the creation of intricate patterns without compromising structural integrity. This progress leads to tailored solutions that meet diverse application requirements, reinforcing the mesh's status as a versatile tool across industries.

In summary, heavy duty metal screen mesh offers a reliable, cost-efficient solution for complex filtration, separation, and design needs. Its enduring popularity across various sectors is a testament to its robust nature and adaptability. By aligning with renowned standards and leveraging expert advice, users can achieve optimal results, ensuring their projects are supported by materials that combine strength, beauty, and resilience. Whether for industrial purposes or creative architectural endeavors, heavy duty metal screen mesh remains an essential component, bearing unyielding performance with every use.