Heavy duty expanded metal is a pivotal component across various industries, known for its exceptional strength, versatility, and durable nature. Different from ordinary expanded metal, this type stands out due to its significantly thicker strands and bonds, making it ideal for rigorous applications. Let's delve into what makes heavy duty expanded metal a premium choice for industrial and structural uses.

Harnessing the strength of metal sheets, manufacturers transform them into expanded metal by simultaneously cutting and stretching the sheet. The process results in a mesh pattern that not only amplifies the strength and durability but also optimizes the weight-to-strength ratio, crucial for heavy-duty applications. The inherent properties of this material make it particularly valuable in environments where lightweight yet strong materials are required, such as in the construction, transportation, and defense industries.

In construction, heavy duty expanded metal offers a practical solution for reinforcing concrete, enhancing load-bearing walls, and forming structures like walkways and platforms. Its open mesh design allows for easy passage of light, heat, and air, which not only reduces weight but also increases the safety and aesthetics of the structure. Moreover, the material is resilient against harsh weather conditions and corrosion, making it a trustworthy option for outdoor and maritime environments.

The transportation sector also greatly benefits from this innovation. Heavy duty expanded metal is frequently used in the manufacture of vehicle grilles, mesh systems for ventilation, and flooring, especially in commercial and military vehicles. Its ability to endure strenuous conditions without succumbing to wear and tear ensures long service life, minimizing maintenance and replacement costs—essential factors for fleet operations.

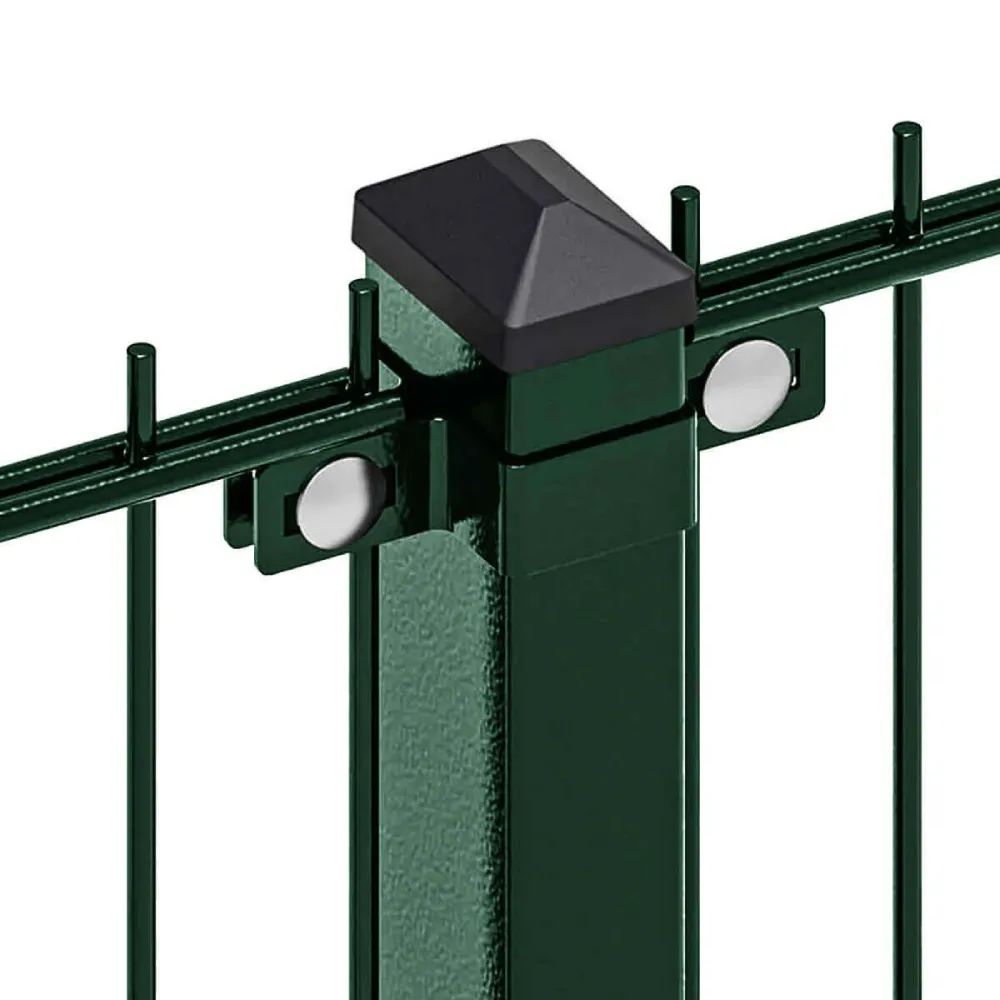

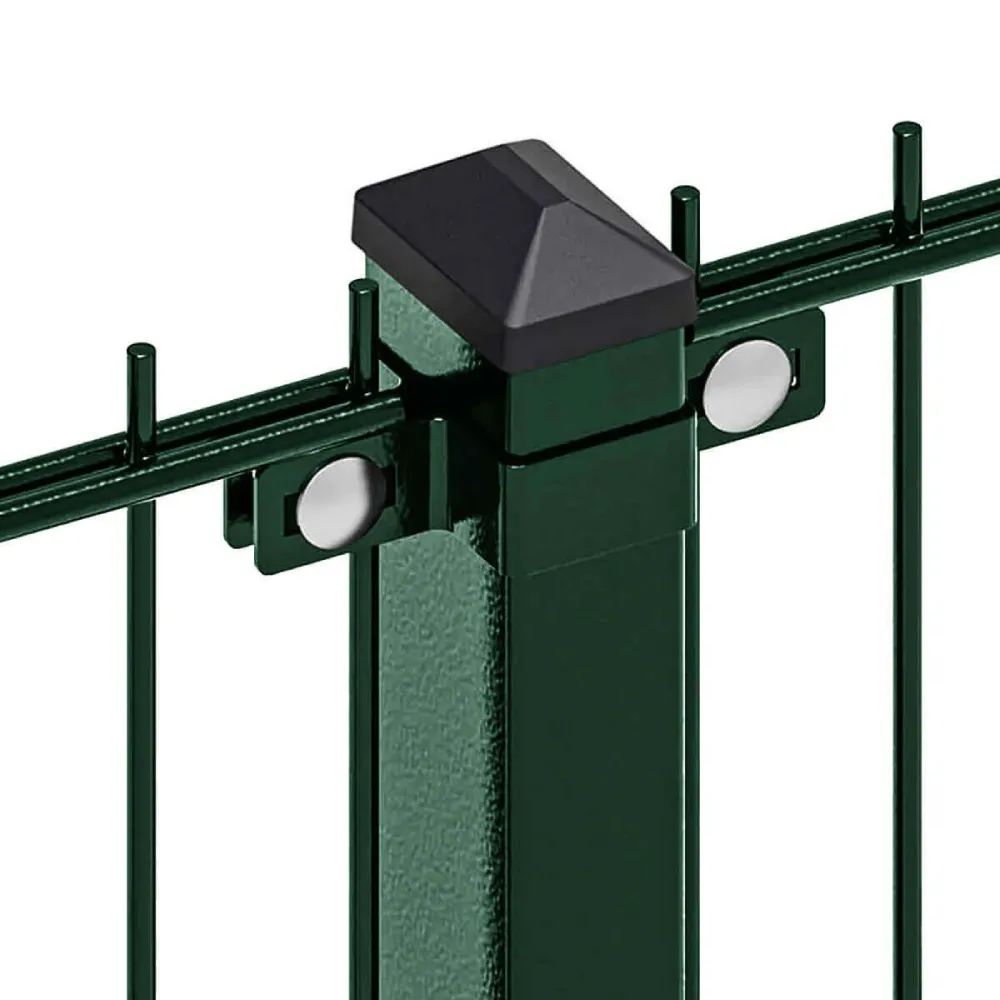

heavy duty expanded metal

Furthermore, industries involved in security and protection have found heavy duty expanded metal indispensable. The material's robustness provides effective solutions for securing facilities with fences, barriers, and security mesh. Unlike traditional fencing materials, expanded metal does not unravel and is hard to cut, making it an ideal deterrent against unauthorized access and vandalism.

Expert selection and installation of heavy duty expanded metal are paramount to maximizing its benefits. Buyers should prioritize products that meet or exceed industry standards, ensuring they receive the highest quality metal that meets expected performance requirements. Professional consultation and installation by experienced personnel further assure the reliability and effectiveness of the product in its intended application.

Trust in heavy duty expanded metal is bolstered by evidence-based performance in real-world scenarios. Reputable brands often provide case studies and testimonials from satisfied clients, reinforcing the material's capabilities and credible reputation. These endorsements ensure that clients are investing in a solution that has been tried, tested, and approved by peers across various fields.

In summary, heavy duty expanded metal continues to be at the forefront of industrial substrates by offering unmatched strength, versatility, and endurance. Its diverse applications across numerous industries not only demonstrate its capability but also emphasize its necessity in modern infrastructure and technology. When considering enhanced performance, reliability, and cost-effectiveness in industrial applications, heavy duty expanded metal undoubtedly stands as a premier material choice.