Galvanised steel grating has revolutionized the industrial and architectural fields with its remarkable blend of durability and functionality. As one of the most sought-after products for flooring and structural applications, galvanised steel grating provides unparalleled advantages that are essential for businesses and projects demanding reliability and long-term performance.

Drawing upon extensive industry expertise, one can appreciate the unique process involved in creating galvanised steel grating. It begins with the selection of high-quality steel, which is then subjected to a hot-dip galvanizing process. This involves coating the steel with a layer of zinc, providing exceptional resistance to corrosion and rust, even in the harshest environments. The galvanisation not only enhances the material's longevity but also its load-bearing capacity, making it ideal for heavy-duty operations.

Expert craftsmanship plays a pivotal role in shaping galvanised steel gratings that meet the specific standards required by different industries. These gratings are designed to accommodate a range of custom specifications, including size, mesh type, and bearing bar thickness, ensuring that the product can be tailored to the precise needs of any project. Whether for industrial plants, construction sites, or architectural projects, these bespoke solutions underline the versatility of galvanised steel grating.

In real-world applications, galvanised steel grating shines due to its exceptional experience in providing both safety and reliability. It is particularly valued in industries like petrochemical, mining, and manufacturing, where safety is paramount. The gratings often feature slip-resistant surfaces, reducing the risk of accidents in wet or oily conditions. This safety feature is indispensable for maintaining an accident-free workplace, further solidifying the trustworthiness of galvanised steel grating.

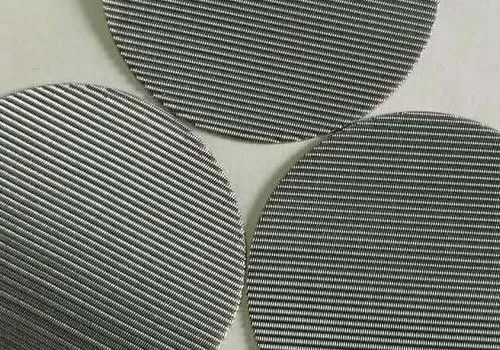

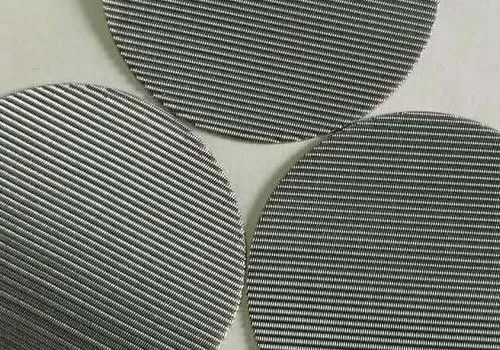

galvanised steel grating

Authoritativeness is a key attribute of companies that produce and supply galvanised steel grating. Industry leaders often possess decades of experience and are certified by reputable bodies that enforce rigorous safety and quality standards. These companies not only supply superior products but also provide critical insights and guidance to clients, helping them make informed decisions regarding their grating requirements. By prioritizing quality control and continuous innovation, these authoritative providers maintain their status as pillars in the sector, fostering confidence among their clientele.

Trustworthiness of galvanised steel grating is constantly verified through rigorous testing protocols that assess load limits, impact resistance, and environmental durability. These tests ensure that every piece of grating can withstand the demands it faces in situ. Moreover, the integrity of galvanisation is periodically evaluated to maintain its protective qualities over time, ensuring that clients receive a product that truly stands the test of time.

Galvanised steel grating's efficiency extends to installation and maintenance as well. Installation is straightforward, often requiring minimal tools and labor, reducing both time and costs. For maintenance, the corrosion-resistant properties ensure that the grating remains largely unaffected by the elements, significantly reducing the need for repairs or replacements. The long service life of galvanised steel grating results in overall cost savings, affirming its value as a wise investment.

In conclusion, the appeal of galvanised steel grating lies in its powerful combination of safety, durability, and adaptability. Its extensive use across various industries is a testament to its trustworthiness and high performance. Companies seeking reliable, high-quality materials for their projects can confidently turn to galvanised steel grating, assured of a product that epitomizes excellence through experience, expertise, authoritativeness, and trustworthiness.